Green battery shell grinding device

A green battery and shell technology, applied in grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve problems such as uneven processing plane, lack of availability, pits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

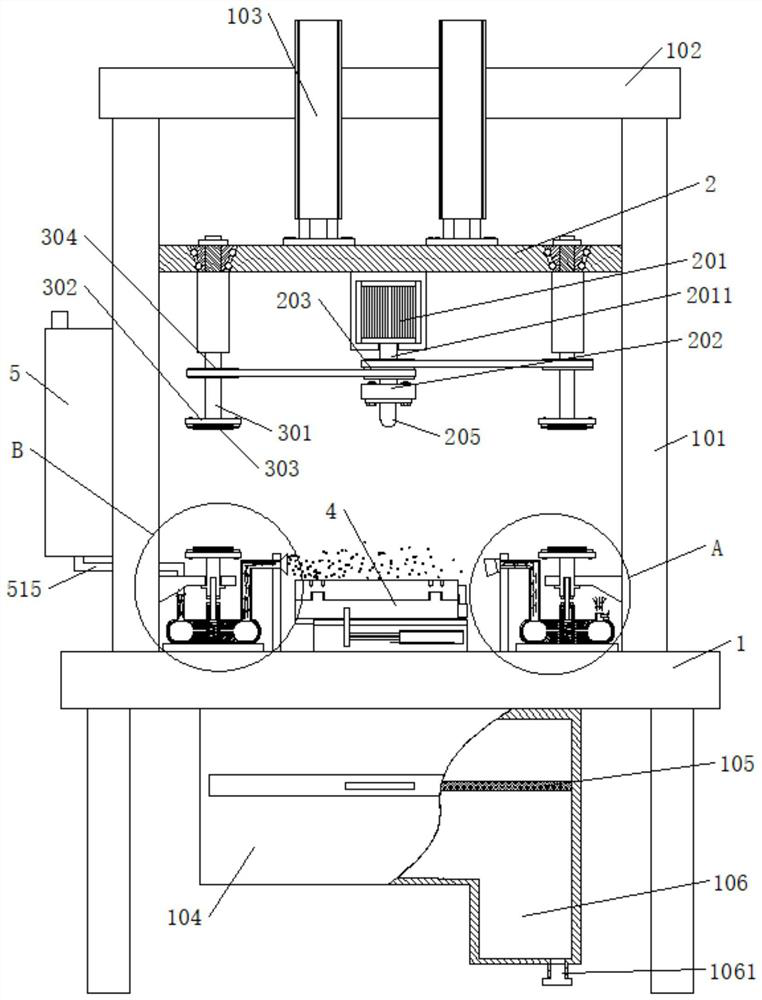

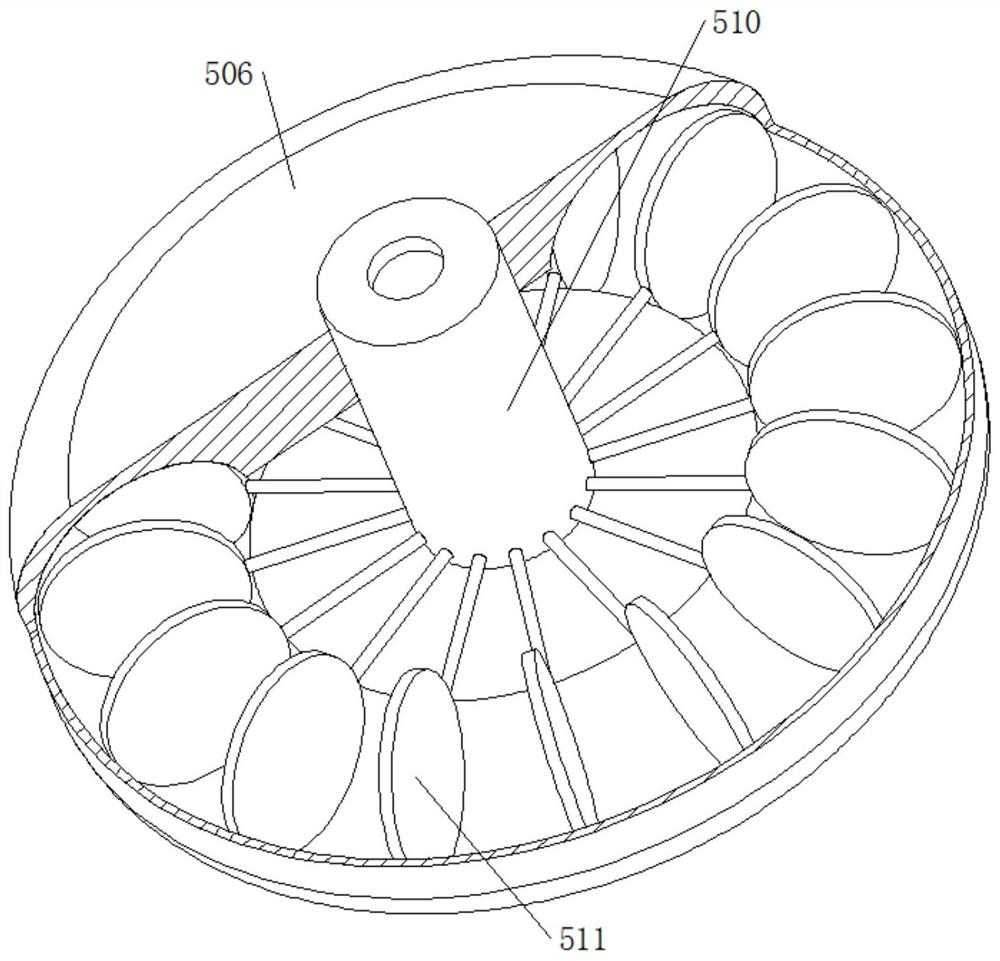

[0032] refer to Figure 1-8, a green battery casing grinding device, comprising a base 1, a workpiece fixture 4, a lifting plate 2, a grinding mechanism and two first rotating shafts 301 rotatably connected to the lifting plate 2, the workpiece fixture 4 is fixedly connected to the base 1, and is polished The mechanism is connected to the bottom of the lifting plate 2, and the two first rotating shafts 301 are rotationally connected with the grinding mechanism. When the grinding mechanism is working, the two first rotating shafts 301 rotate synchronously, and the base 1 is also connected with an air spray mechanism and a liquid spray mechanism; , the air injection mechanism and the liquid injection mechanism both include a housing 506, an arc-shaped through groove is arranged inside the housing 506, the center of the housing 506 is rotatably connected to a second rotating shaft 510, and a plurality of blades 511 are fixedly connected to the outer surface of the second rotating ...

Embodiment 2

[0035] refer to figure 1 , this implementation discloses a specific implementation of the grinding mechanism, the grinding mechanism includes a motor 201, the output end of the motor 201 is connected to a third rotating shaft 2011, the lower end of the third rotating shaft 2011 is detachably connected to a grinding head 205, two first rotating shafts 301 is fixedly connected with a first pulley 304, the third rotating shaft 2011 is fixedly connected with a second pulley 203, and a belt is sleeved on the first pulley 304 and the second pulley 203, and the third rotating shaft 2011 is realized through belt transmission. and the synchronous rotation of the first rotating shaft 301.

[0036] refer to figure 1 , Figure 4 , Figure 5 The bottom of the third rotating shaft 2011 is connected with the first substrate 202, the grinding head 205 is fixedly connected to the first substrate 202 by screws, the lower end of the first rotating shaft 301 is fixedly connected to the second ...

Embodiment 3

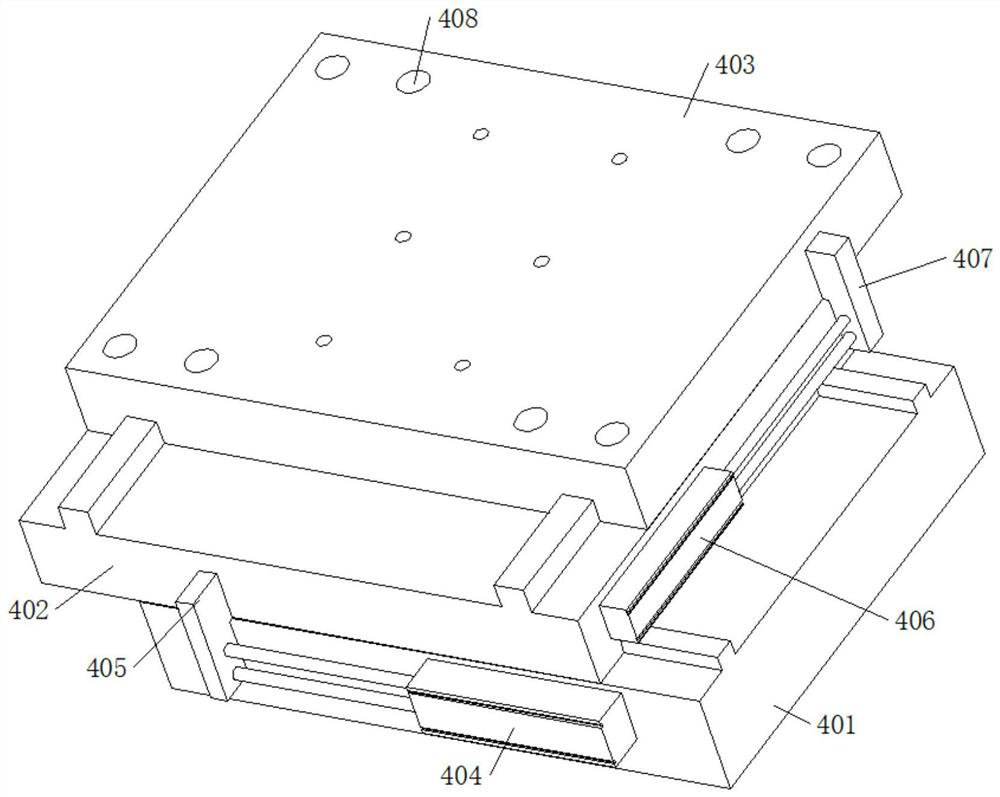

[0040] refer to figure 2 , this implementation discloses a specific implementation of the workpiece holder 4, which includes a first base 401, a second base 402 and a third base 403; wherein, the first base 401 is fixedly connected to the base 1, and the second The base 402 is slidably connected to the first pedestal 401, the third pedestal 403 is slidably connected to the second pedestal 402, and the sliding directions of the second pedestal 402 and the third pedestal 403 are vertical in space, the first The side wall of the base 401 is equipped with a second cylinder 404, the side wall of the second base 402 is fixedly connected with a first fixed plate 405, the output end of the second cylinder 404 is connected with the first fixed plate 405, and the second base 402 is installed There is a third cylinder 406, the side wall of the third base 403 is fixedly connected with a second fixed plate 407, the output end of the third cylinder 406 is connected with the second fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com