Lead smelting tail gas treatment process

A technology for exhaust gas treatment and lead smelting, which is applied in the fields of cleaning hollow objects, separation of dispersed particles, chemical instruments and methods, etc. It can solve the problems of affecting the observation of the treatment tower, the proportion of lead smoke, and the adhesion of lead dust, etc. The effect of increasing dust treatment efficiency and lead dust exposure possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

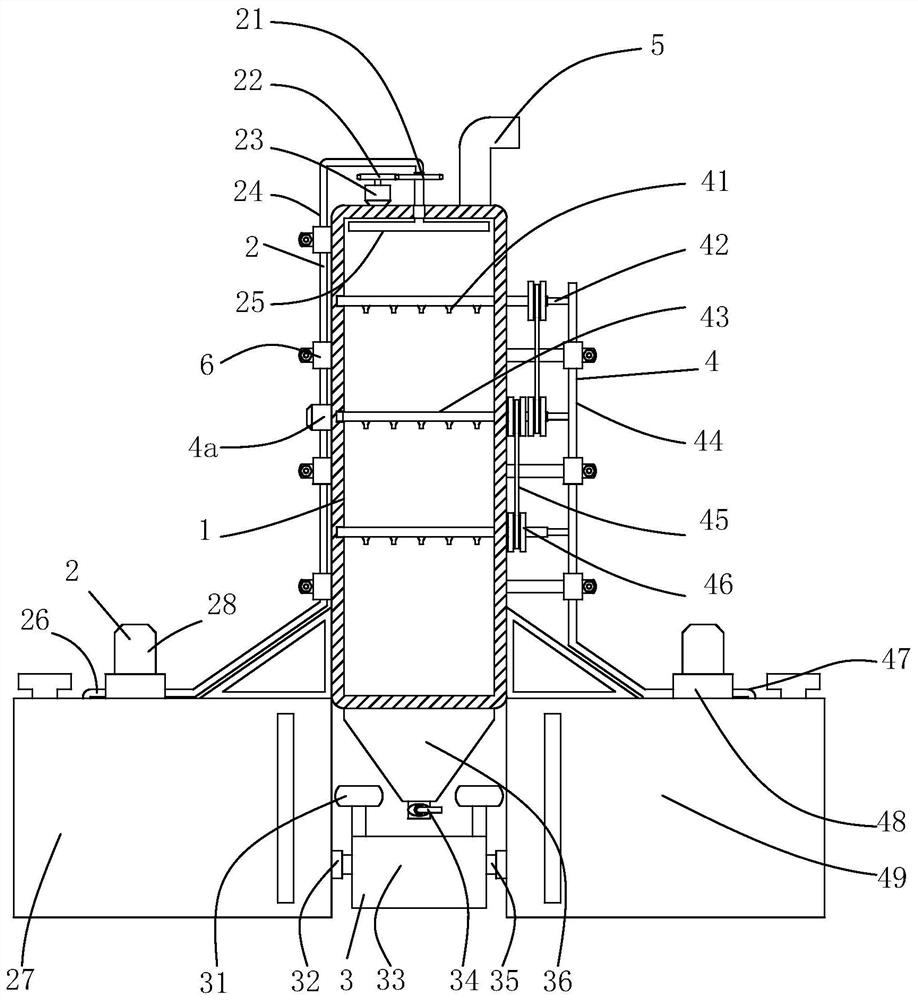

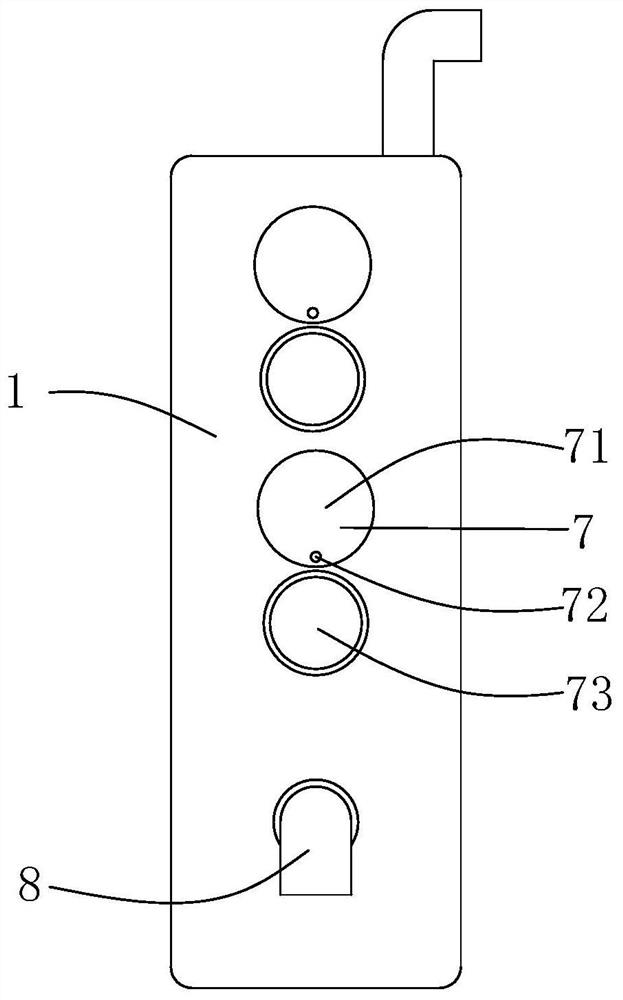

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

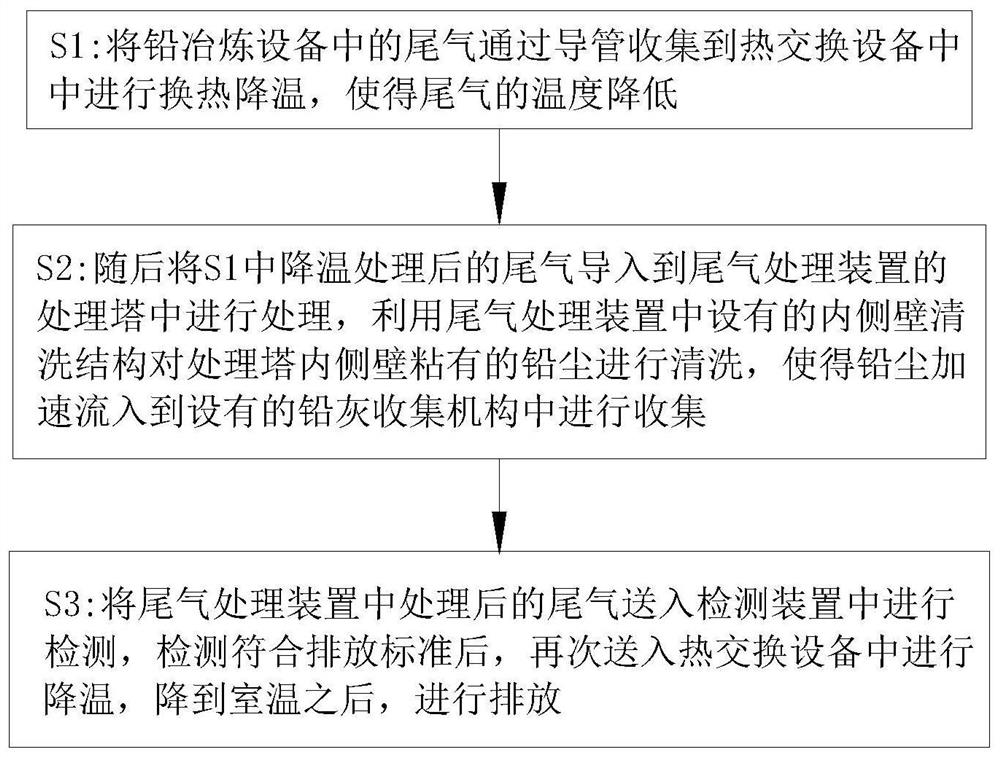

[0024] Please refer to Figure 1-Figure 4 , a lead smelting tail gas treatment process, the process steps are as follows:

[0025] S1: the exhaust gas in the lead smelting equipment is collected in the heat exchange equipment through the conduit for heat exchange and cooling, so that the temperature of the exhaust gas is reduced;

[0026] S2: then the exhaust gas after the cooling treatment in S1 is introduced into the treatment tower of the tail gas treatment device for processing, and the inner wall cleaning structure provided in the tail gas treatment device is used to clean the lead dust adhered to the inner wall of the treatment tower, so that the lead The dust accelerates to flow into the set lead ash collection mechanism for collection;

[0027] S3: Send the tail gas treated in the tail gas treatment device into the detection device for detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com