Organic tea leaf production system

A production system and tea technology, which are applied to conveyors, tea processing before extraction, transportation and packaging, etc., can solve the problems of prolonged rolling time, low efficiency, and inability to meet the demand for pressure rolling of tea leaves. The effect of friction, enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

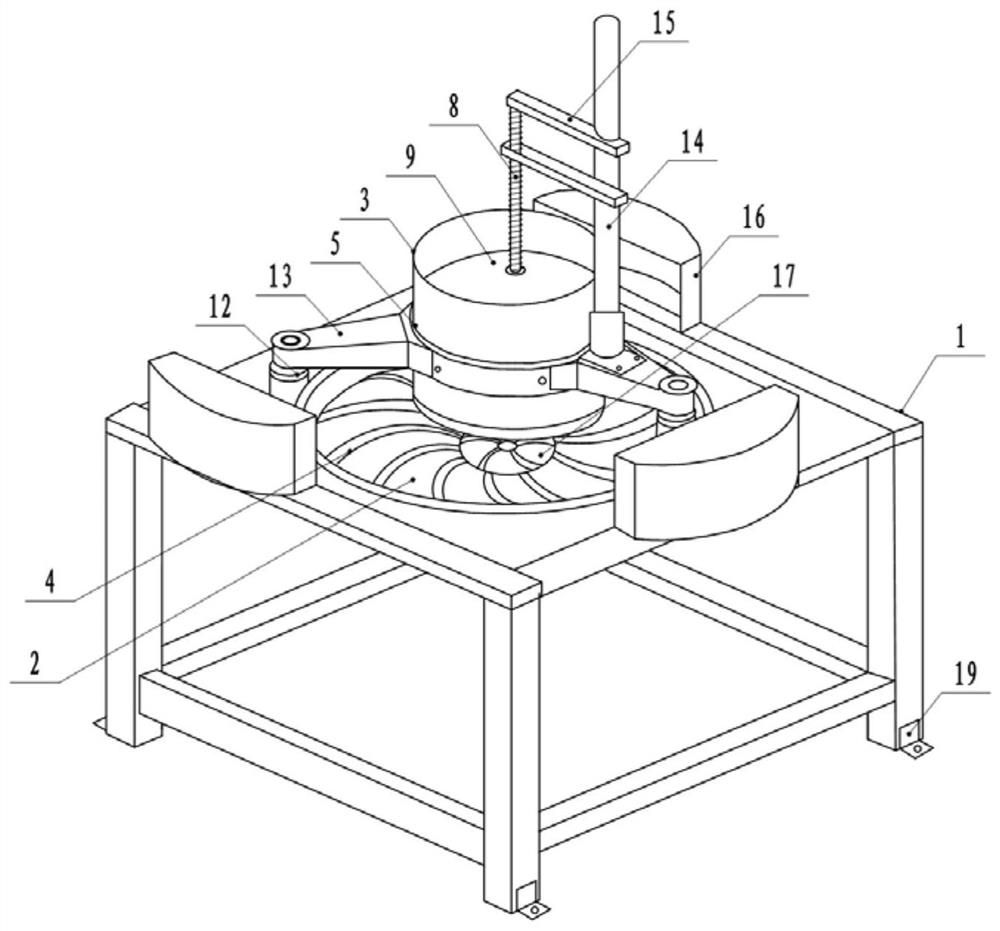

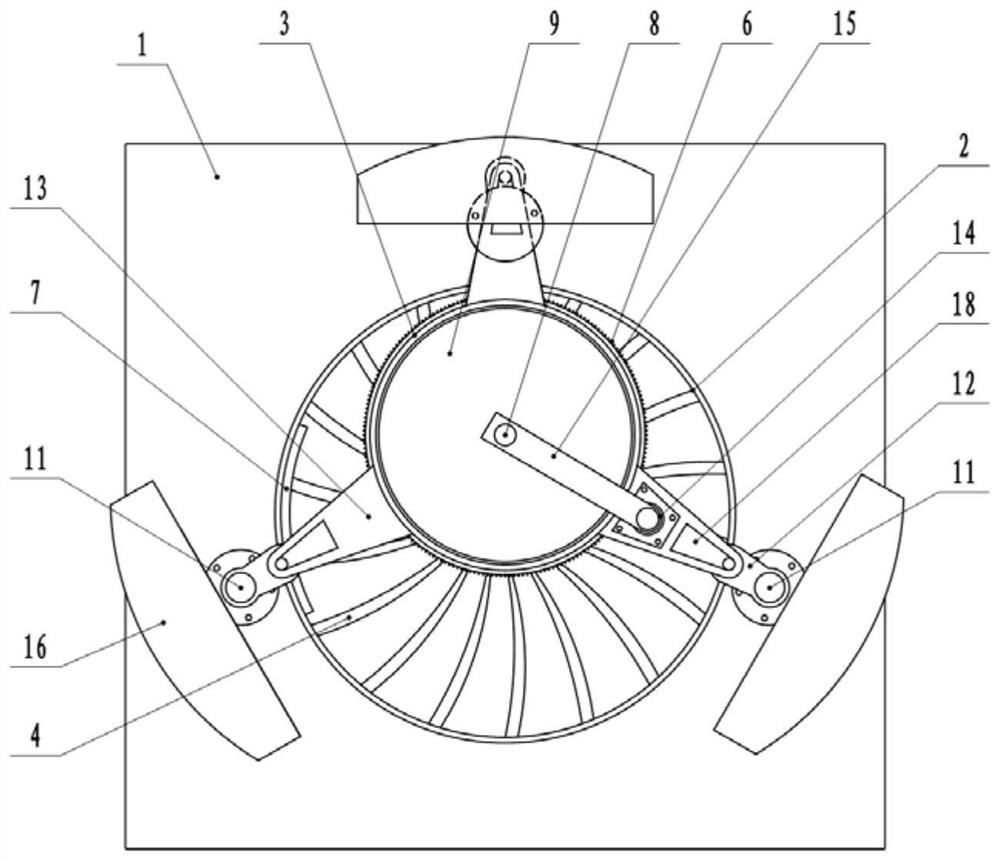

[0034] This embodiment is basically as attached figure 1 Shown: The organic tea production system, including a drum-type degreening device, a rolling device, an aroma enhancing device, a drying device, and a conveying device arranged in sequence between adjacent devices. Wherein, the kneading device includes a frame 1, a kneading disc 2, a kneading barrel 3, a driving mechanism and a pressurizing mechanism.

[0035] Frame 1 plays the role of overall support. Frame 1 includes a support table and four support feet welded on the bottom surface of the support table. Reinforcement sheets 19 are fixed between the support feet and the ground by bolts to ensure stable fixation and avoid The device shakes during use.

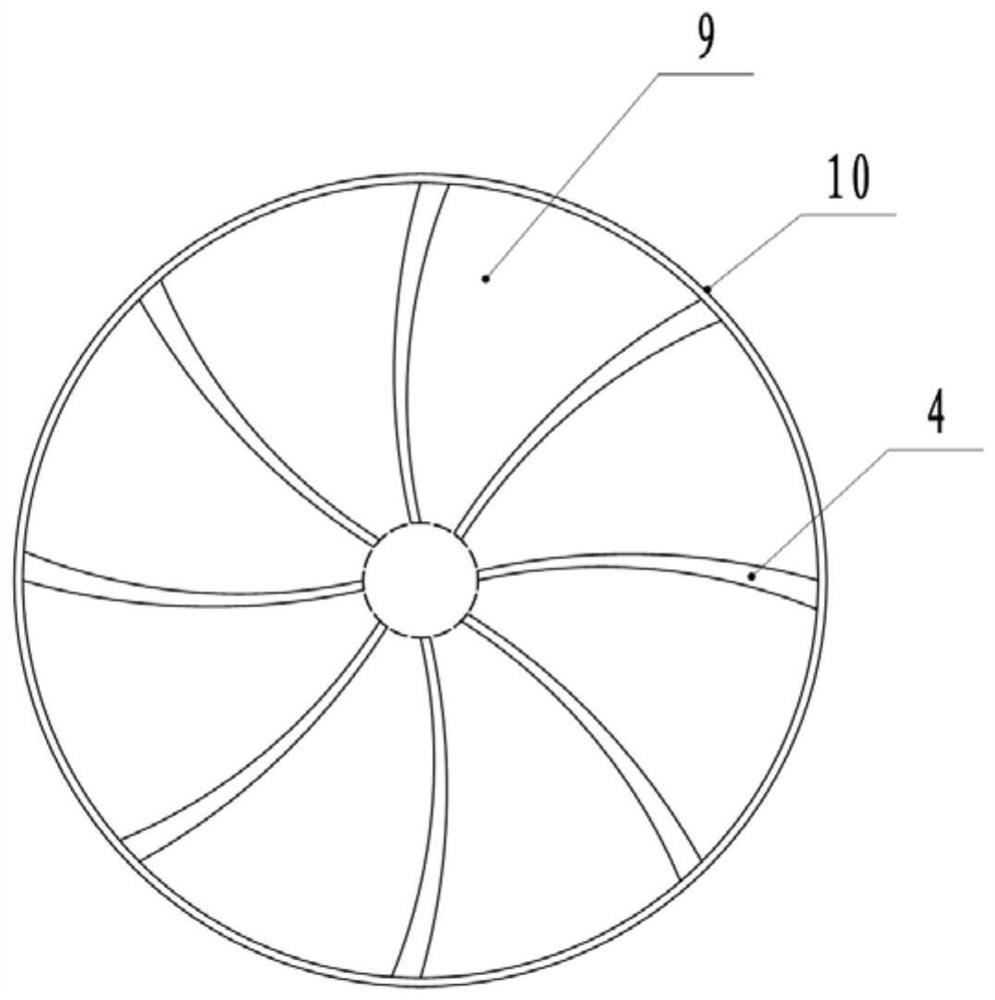

[0036] combine figure 2As shown, the kneading disc 2 is a circular disc structure, and the kneading disc 2 is fixed on the frame 1 by bolts, and several arc-shaped ribs 4 are fixed on the kneading disc 2 . The middle part of the kneading disc 2 is provided with a cir...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that in this embodiment, the drive shaft 11 is telescopically arranged, and the structure of the drive shaft 11 in this embodiment is similar to the structure of the electric telescopic rod in the prior art, that is, it includes a fixed segment and extension, the drive arm 12 is rotatably connected to the extension of the drive shaft 11. The side wall of the kneading disc 2 is provided with an air supply duct, and the air supply duct is connected with a fan, and the side wall of the kneading disc 2 is provided with some blowing outlets communicated with the air supply duct, and the blowing outlets are arranged toward the center of the kneading disc 2 .

[0049] During specific implementation, by setting the drive shaft 11 as telescopic, the lifting function can be used to move the fixed frame 13 and the kneading barrel 3 up and lift after the tea leaves are rolled, so as to facilitate the cleaning of the tea resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com