A kind of metamaterial structure and preparation method thereof

A technology of metamaterials and non-metallic materials, applied in the field of new metamaterials and its preparation, can solve problems such as difficult conformation, easy corrosion, high cost, etc., achieve high ductility and conformality, and reduce preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Specifically, the present invention also proposes a method for preparing a novel metamaterial structure, comprising the following steps:

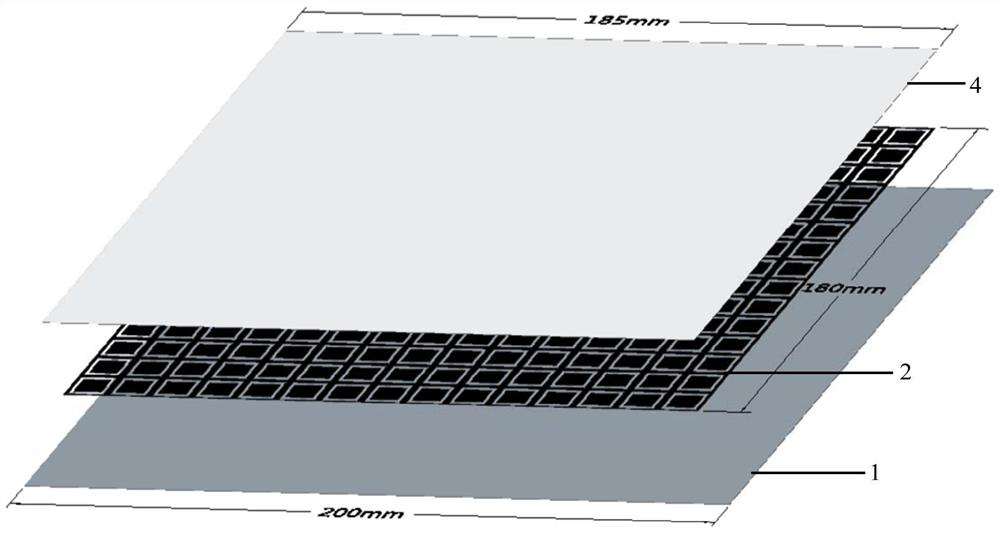

[0042] Step a, prepare a 20×20cm substrate 1, clean the printing surface of the substrate 1 with acetone or alcohol solvent, and dry it naturally;

[0043] The specific method of pressing the substrate 1 is: placing the flexible substrate 1 on a flat vulcanizing machine, pressing for 15 minutes under the conditions of an upper plate temperature of 100° C., a lower plate temperature of 110° C., and a pressure of 4.0 MPa, with a pressing thickness of 0.2 mm.

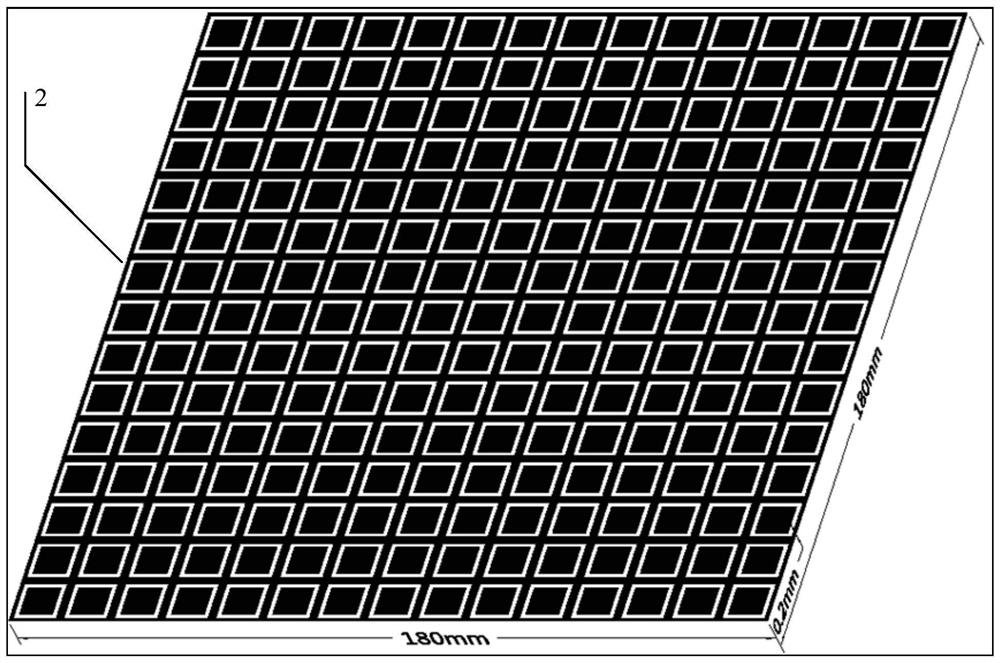

[0044] Step b, design the pattern of the periodic slot array unit 3 for printing, and the periodic slot array unit 3 is arranged n in the manner of n×n 2 For example, if the substrate 1 adopts a square size of 20 × 20 cm, and n=15, a total of 225 periodic slot array units are arranged.

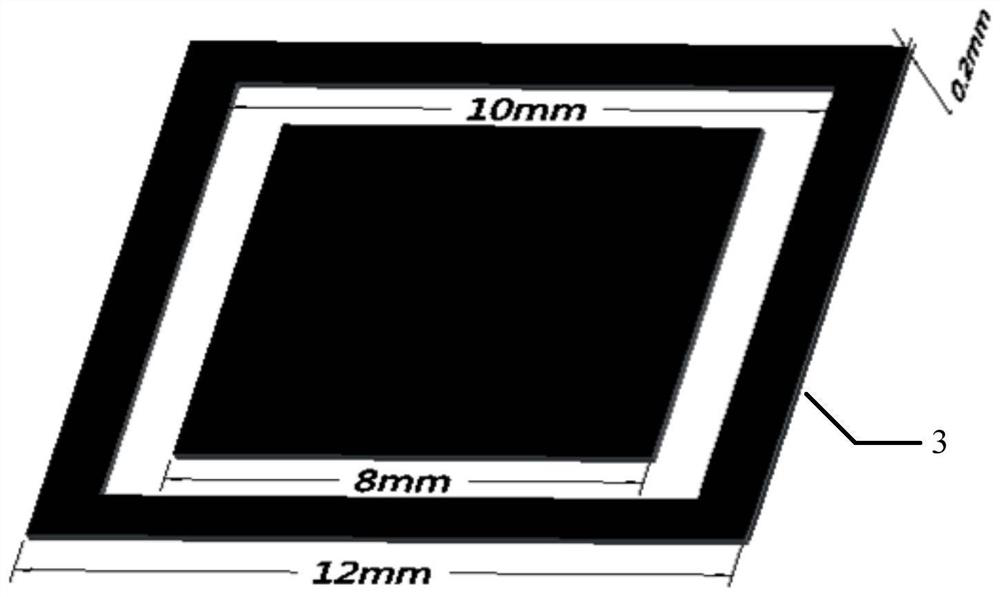

[0045] The periodic slot array unit 3 adopts a square slot pattern, the size of which is: th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com