Process method for eliminating micro short circuit in production of functional sheet by using megohmmeter

A process method and technology of megohmmeter, applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as inability to cut with sharp blades, achieve the effects of not being prone to secondary defects, improving the straight-through rate, and reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

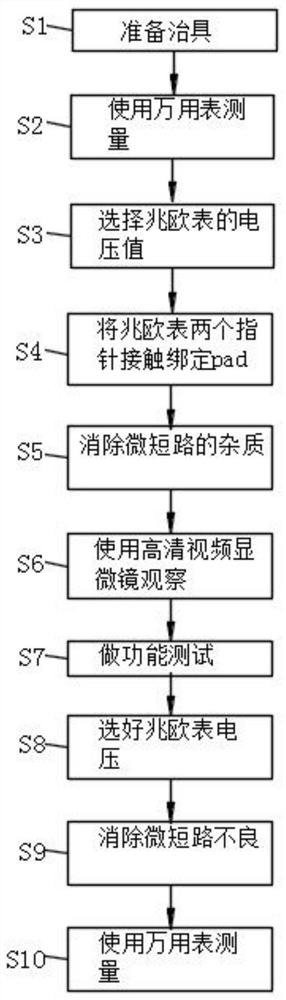

[0029] The invention provides a technical solution: as figure 1 As shown, a process method for eliminating micro-short circuits in the production of functional chips by using a megohmmeter includes the following specific steps:

[0030] Step 1. Prepare the fixture: multimeter with M ohm gear, megohmmeter, and high-definition video microscope. The model of the multimeter is: VICTORVC9807A+, the model of the megger is: VICTORVC60B+, and the model of the high-definition video microscope is: TTL.HK, 15 -45 times.

[0031] Step 2. After the silver paste is laser etched, use a multimeter to measure and check the micro-short circuit of the silver paste line. The multimeter is adjusted to 200MΩ for measurement. Two pointers touch two adjacent ITO channels. The multimeter shows that it is greater than 0.1MΩ, which is micro Short circuit, the ITO channel is the test channel impedance, which is greater than 0.1MΩ, and it is a micro-short circuit between 0 and tens of MΩ.

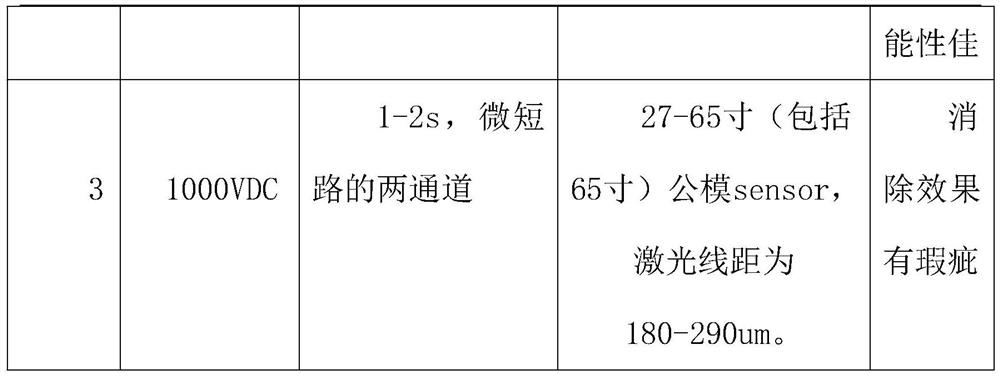

[0032] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com