Dismantling and troubleshooting method of an oil-immersed vertical current transformer

A current transformer and vertical technology, which is applied in the field of dismantling and defect investigation of oil-immersed vertical current transformers, can solve the problems of insufficient dismantling experience, insufficient dismantling methods, and no results. Improve the efficiency of dismantling, help to find the location of defects and infer the cause of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

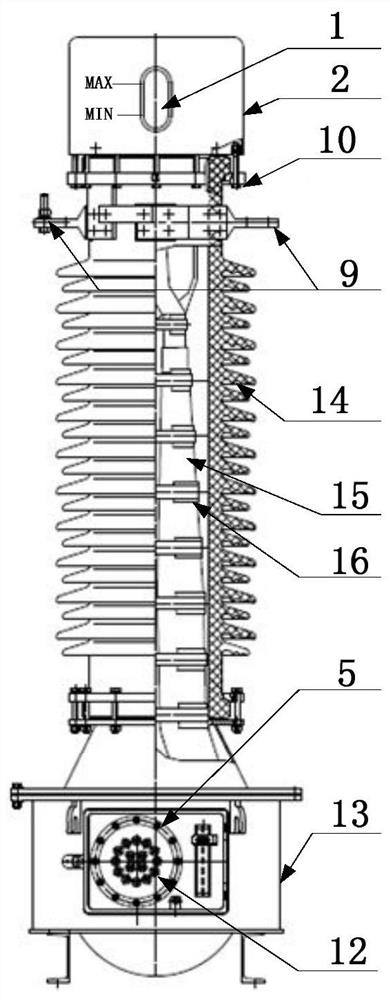

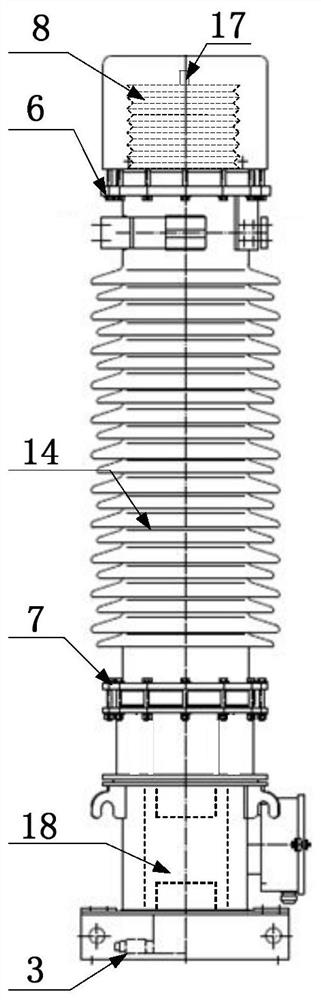

[0086] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0087] The invention provides a method for dismantling an oil-immersed upright current transformer and its defect checking method. The defect refers to the defects in the equipment body of the oil-immersed vertical current transformer, and the oil-immersed vertical current transformer with defects in the equipment body is recorded as the transformer to be checked. The disassembly and its defects The inspection method is carried out on the transformer to be inspected, that is, defect inspection is carried out during the disassembly process of the transformer to be inspected.

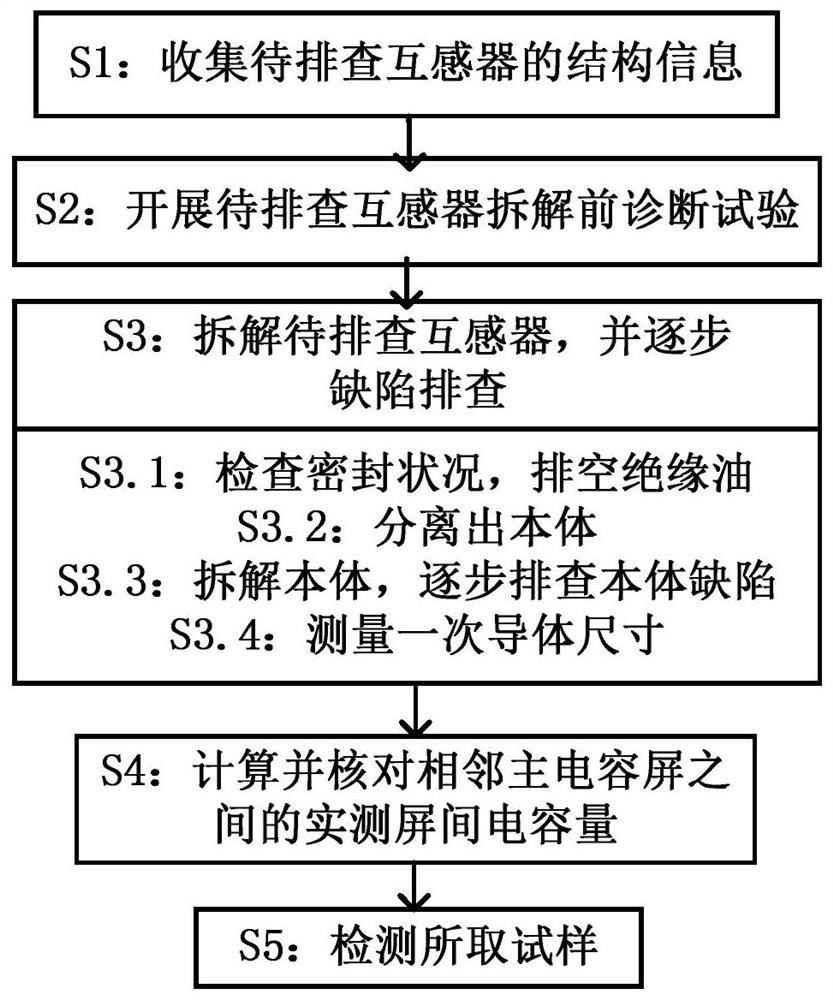

[0088] figure 1 It is a schematic diagram of the dismantling and defect troubleshooting process of the oil-immersed vertical current transformer, by figure 1 It can be seen that the dismantling and defect troubleshooting method includes the following dismantling and tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com