Plate heat exchanger with water storage tank

A technology of plate heat exchanger and water storage tank, applied in the direction of heat exchanger type, indirect heat exchanger, fluid heater, etc., can solve the difficulty of welding the semi-closed cavity and the back plate, and the difficulty of manufacturing the semi-closed cavity , affecting the user experience and other issues, to achieve the effect of improving the user experience, compact structure, and stable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

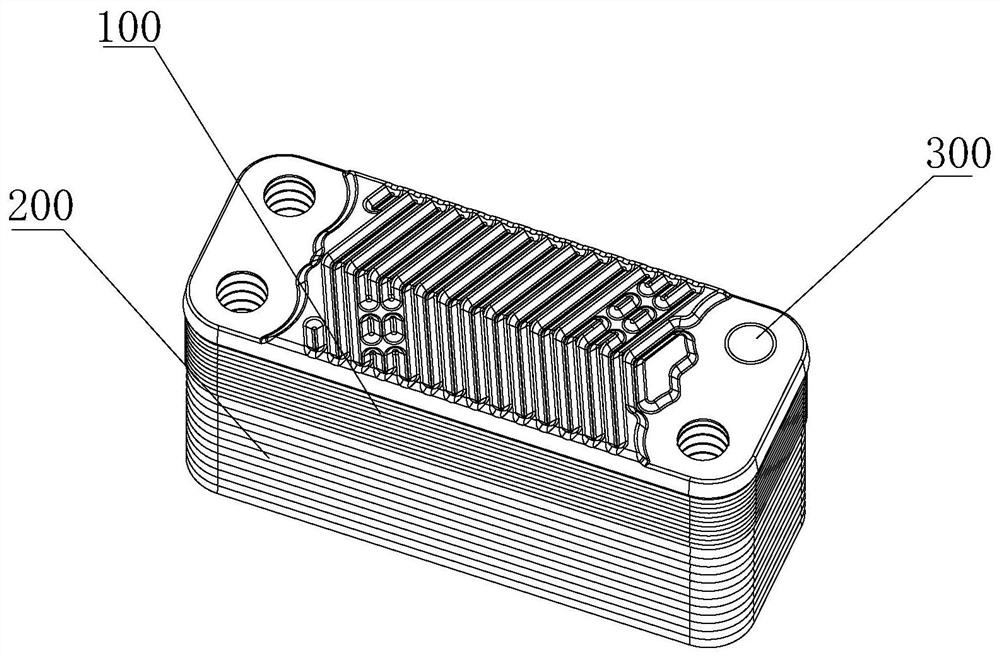

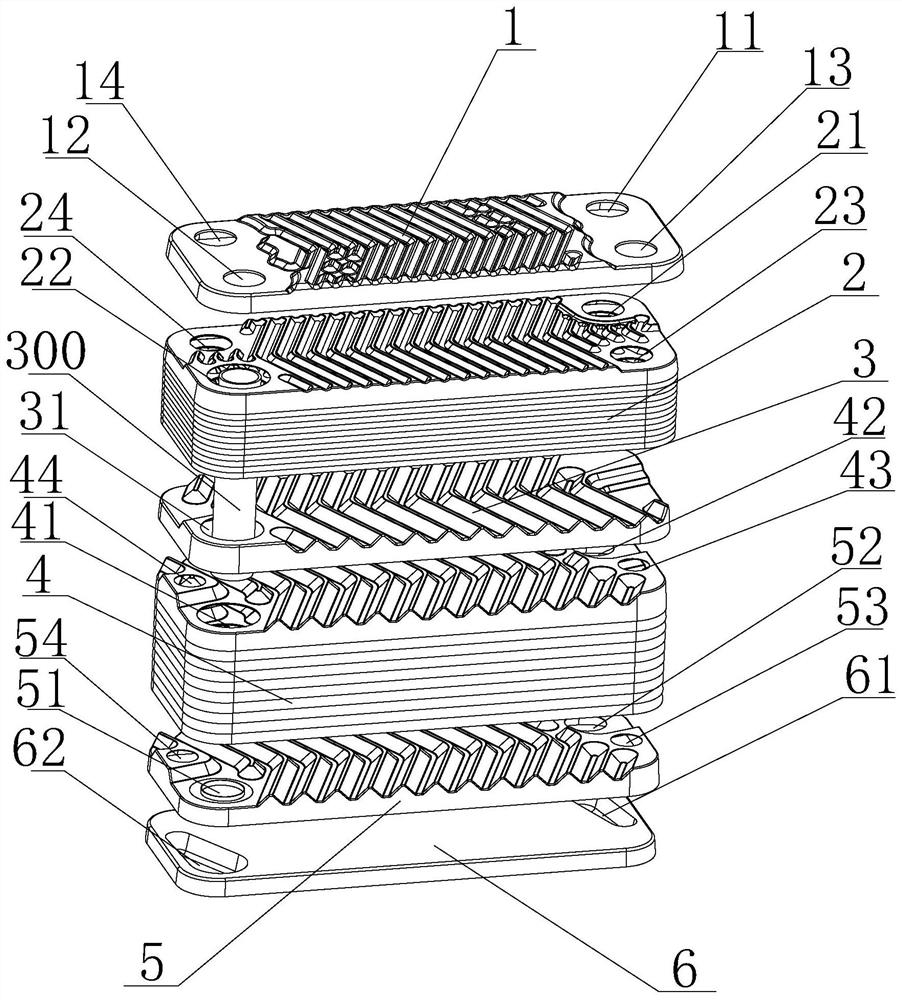

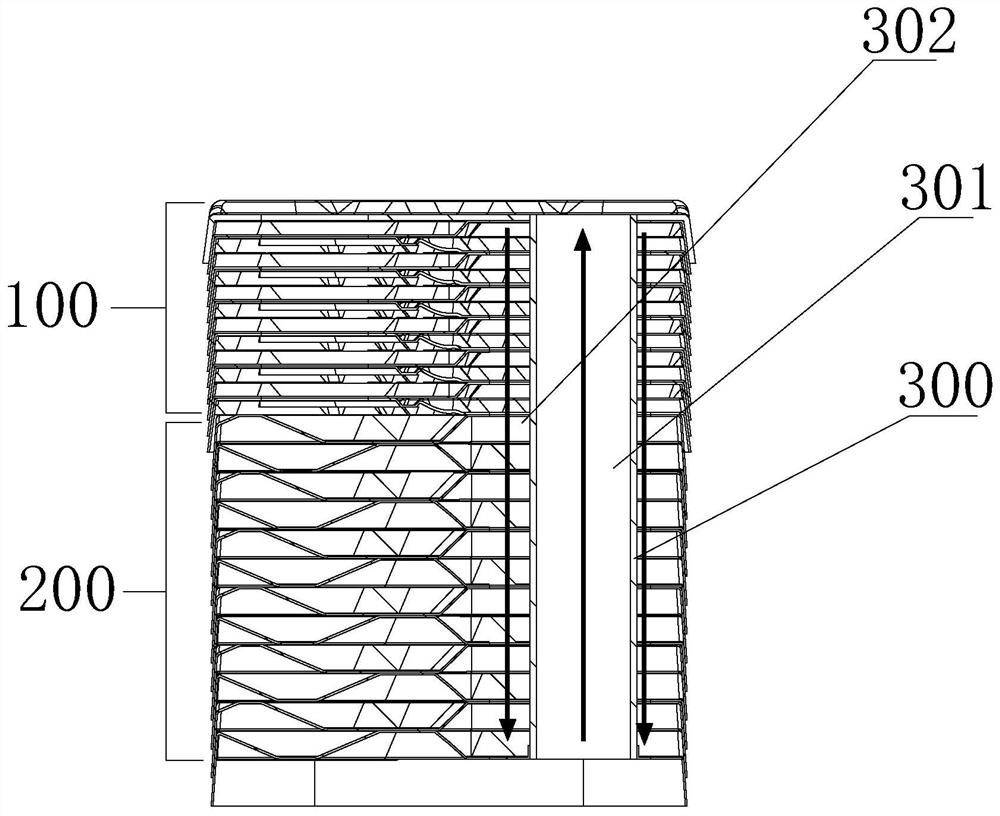

[0030] A kind of plate heat exchanger with water storage tank of the present invention such as figure 1 , figure 2 and image 3 As shown, it includes a heat exchange main body 100, a water tank main body 200 and a water outlet pipe 300. The heat exchange main body 100 has a bathroom water inlet channel 21, a bathroom water outlet channel 22, a heating water inlet channel 23 and a heating water outlet channel 24, wherein the heat exchange The heating water inlet channel 23 and the heating water outlet channel 24 of the main body 100 are generally connected with gas water heaters or wall-hung boiler pipelines to provide high temperature water, and the bathroom water inlet channel 21 of the heat exchange main body 100 is ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com