Raw paper pulp

A raw pulp and paper technology, applied in the direction of natural cellulose pulp/paper, papermaking, non-woody plant/crop pulp, etc., can solve problems such as insufficient hardness and smoothness of paper, product quality impact, product packaging damage, etc. , to achieve the effect of high hardness of paper material, beautiful shape and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1, a kind of paper protoplasm, described protoplasm comprises the leaf fiber pulp of dicotyledonous plant, and described leaf fiber pulp comprises plant leaf fiber pulp of the genus Quercus, plant leaf fiber pulp of the genus Quercus, leaf fiber pulp of the genus Populus The fiber pulp and the leaf fiber pulp of the genus Cyclops, wherein the composition ratio of the fiber pulp of the leaf is: 20% of the fiber pulp of the leaf of the plant of the genus Quercus, 30% of the fiber pulp of the leaf of the plant of the genus Quercus, and 20% of the fiber pulp of the leaf of the plant of the genus Populus The paper material made from 30% of the leaf fiber pulp of Hessicola genus plant without mixing other original pulp has good strength characteristics and can be applied to industrial product packaging.

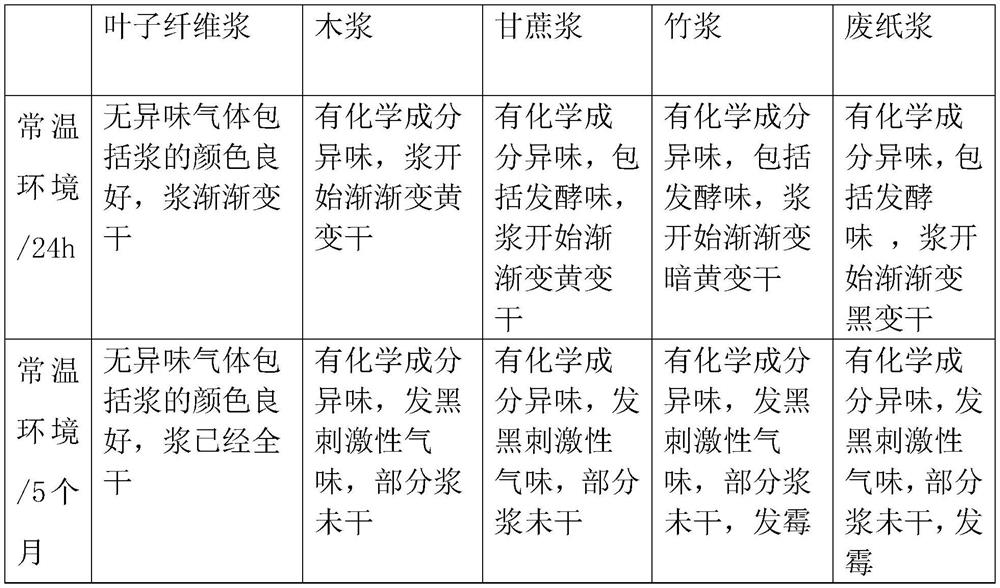

[0011] And the leaf fiber pulp and wood pulp, sugarcane pulp, bamboo pulp and waste paper pulp were tested for their antibacterial properties under the same enviro...

Embodiment 2

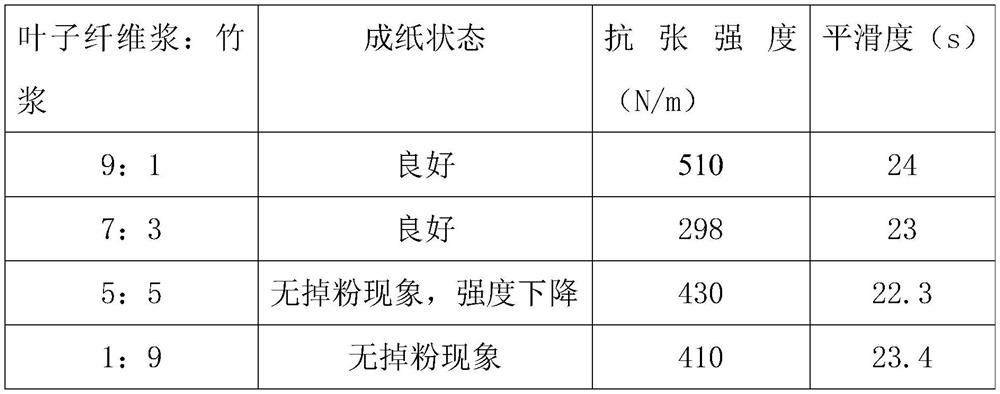

[0015] Embodiment 2, a kind of paper raw pulp, described raw pulp comprises the leaf fiber pulp of dicotyledonous plant and non-wood pulp, and non-wood pulp is the bamboo pulp in gramineous fiber pulp, and leaf fiber pulp comprises the plant leaf fiber Pulp, Quercus plant leaf fiber pulp, Populus plant leaf fiber pulp and Aquacantha plant leaf fiber pulp, the composition ratio of leaf fiber pulp is: 25% of Quercus plant leaf fiber pulp, Quercus leaf fiber pulp 25%, Populus plant leaf fiber pulp 25% and Hyacinthium plant leaf fiber pulp 25%, while bamboo pulp accounts for 10% to 90% of the total raw pulp, and the addition of bamboo pulp is 10%, 30% %, 50% and 90%, the performance test is carried out on the paper sheet made, and the test results are shown in Table 2;

[0016]

[0017] Table 2

[0018] As shown in Table 2, the leaf fiber pulp has good strength characteristics, and a certain proportion of leaf fiber pulp can be added to the poor pulp to improve the strength. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com