Automatic clearing method and automatic clearing device of spinning frame

An automatic cleaning and spinning frame technology, applied in textiles and papermaking, etc., can solve the problems of cutter collision, affecting the safe production of spinning frames, and affecting the efficient use of yarn cutters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

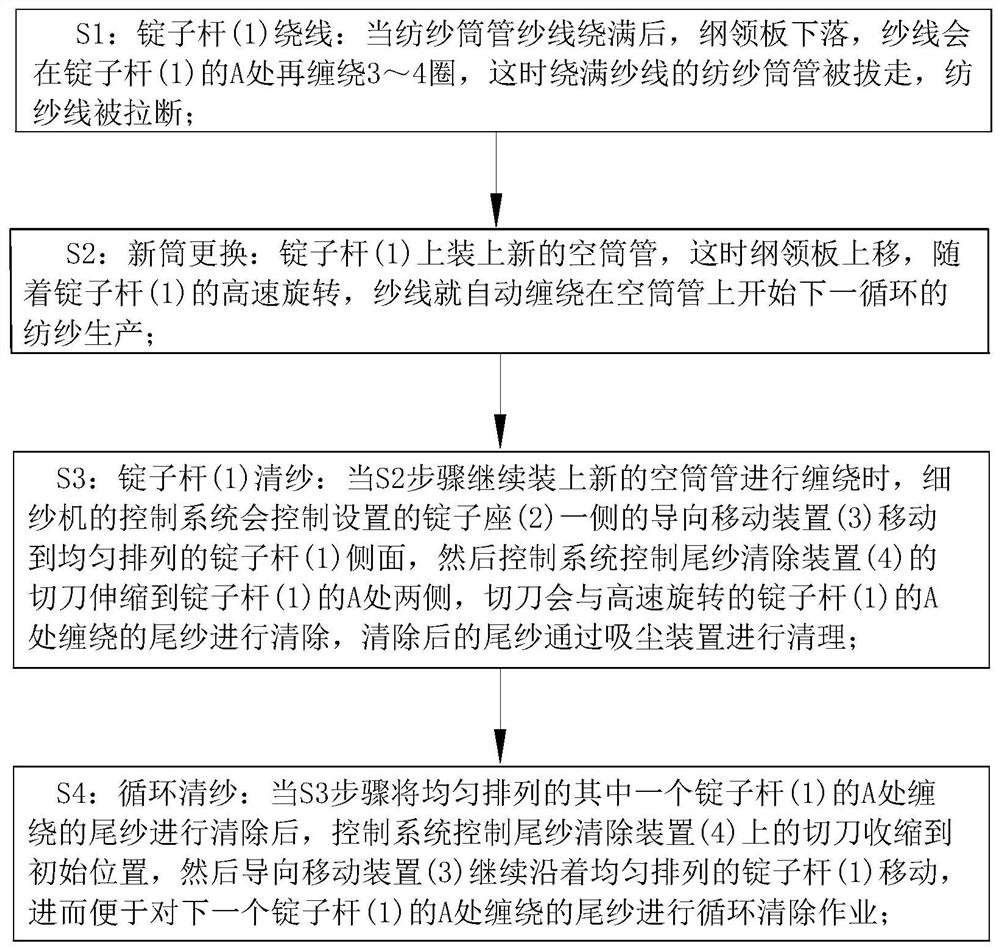

Method used

Image

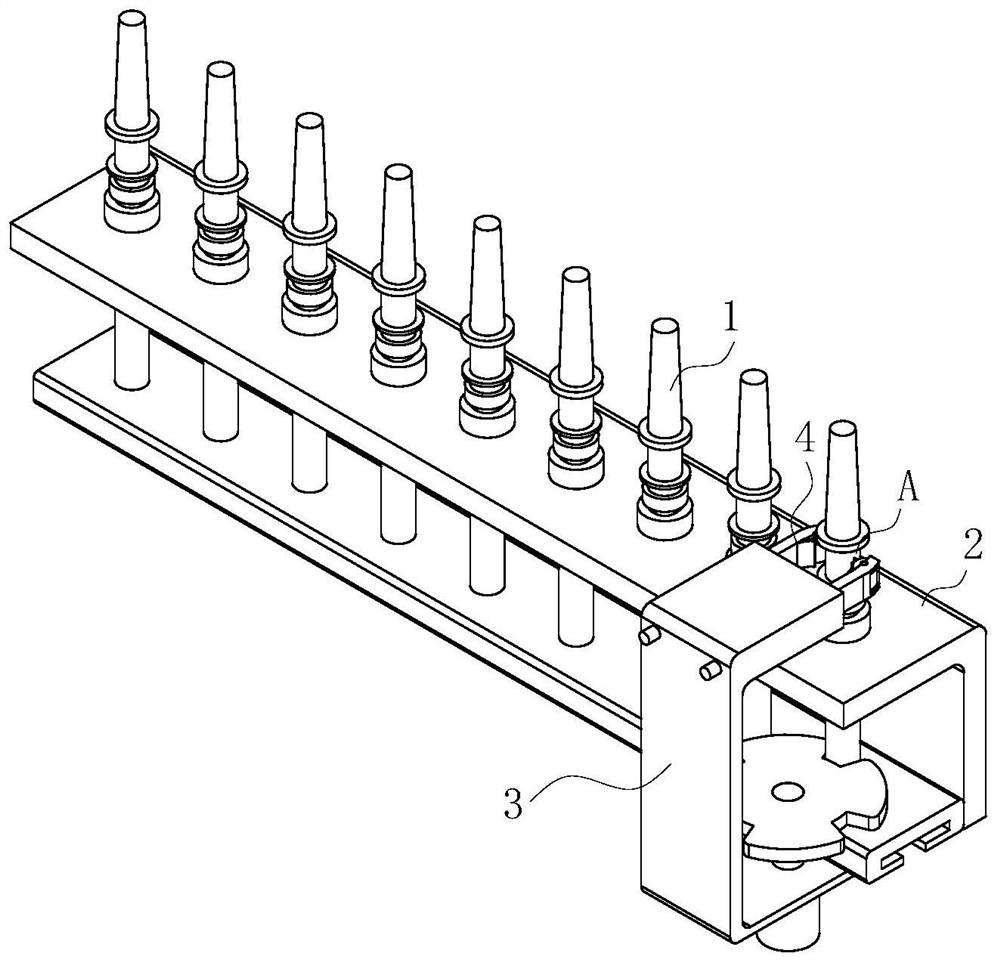

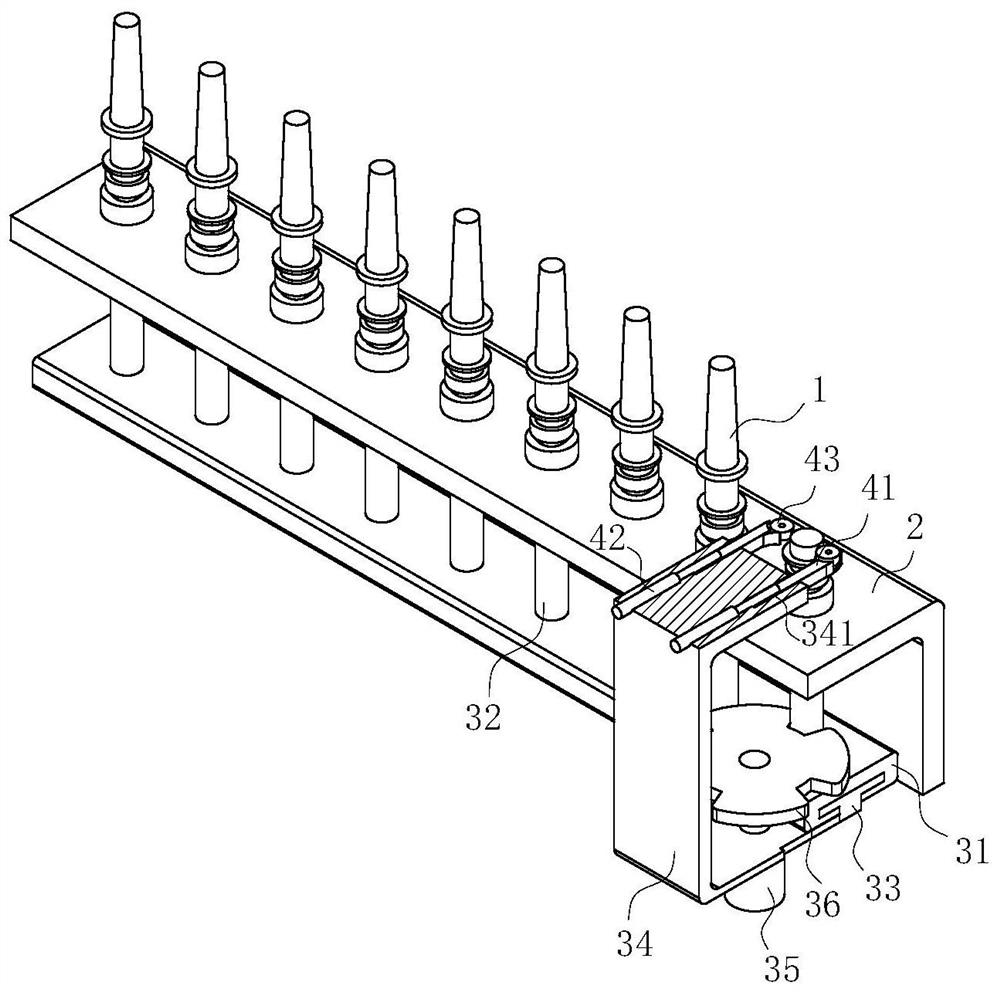

Examples

Embodiment approach

[0041] As an embodiment of the present invention, a collection cavity 61 is opened inside the elastic buffer plate 6, and a dust suction hole 62 is opened on the outer wall of the collection cavity 61; the bottom end of the collection cavity 61 is connected with a suction hose 7, and the dust suction hose 7 is connected with the vacuum cleaner attached to the spinning frame; when the cutting knife 5 cuts and cleans the tail thread wound on the outer wall of the spindle bar 1, due to the rotation of the end of the conical bent piece 52 and the spindle bar 1 The direction is opposite, and then when the conical bent piece 52 removes the tail wire wound on the spindle rod 1, the tail wire will hit the elastic buffer plate 6 under the high-speed centrifugal force of the spindle rod 1, and then the suction force of the vacuum cleaner will pass through the suction. The dust hose 7 sucks the dust generated by the tail line into the collection chamber 61 through the dust suction hole 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com