Construction and application of anti-bacteriophage escherichia coli chassis cell

A technology of Escherichia coli and cells, applied in the field of genetic engineering and microbial engineering, can solve the problems of strict requirements, unable to fundamentally solve the phage infection, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Construction of yafC overexpression strain BL21 / pET28a(+)-YafC

[0039] Specific steps are as follows:

[0040] (1) Design primers YafC-F and YafC-R according to the nucleotide sequence of Escherichia coli BL21 phage resistance protein YafC coding gene yafC (nucleotide sequence shown in SEQ ID No.2), with Escherichia coli BL21 genomic DNA as The template is amplified to obtain a DNA fragment containing the yafC gene sequence, and the DNA fragment is connected to the pET28a (+) plasmid after digestion with BamHI enzyme and EcoRI enzyme to obtain the recombinant plasmid pET28a (+)-YafC; Plasmid pET28a(+)-YafC was transformed into E. coli (Escherichia coli) BL21, and the transformation solution was spread on LB plates containing 100 μg / mL Kanna resistance, and cultured at 37°C until a single colony grew; pick a single colony to LB liquid medium containing 100 μg / mL of Kanna resistance, cultivated at 37°C and 200 rpm for 8-12 hours, extracted the plasmid in the ...

Embodiment 2

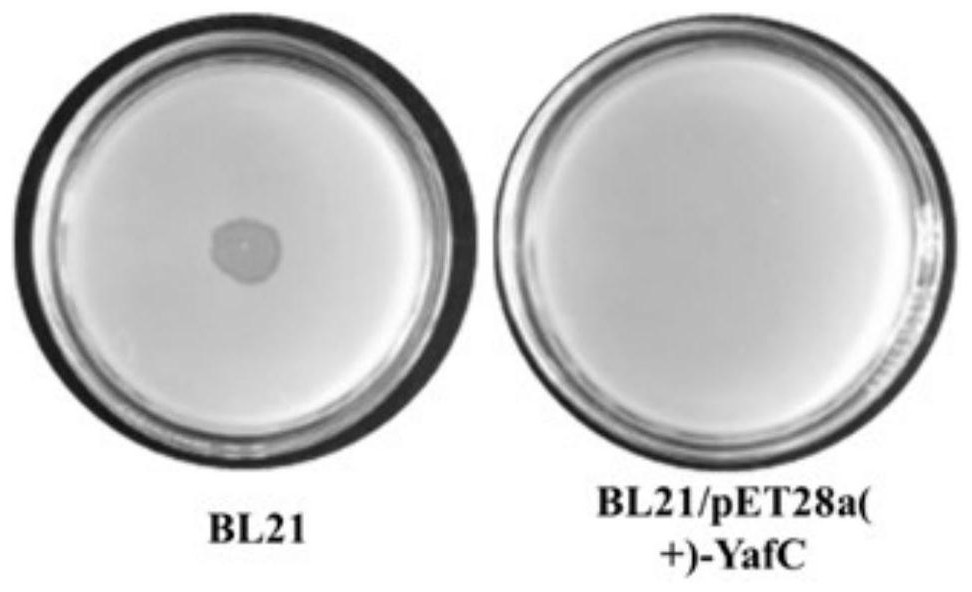

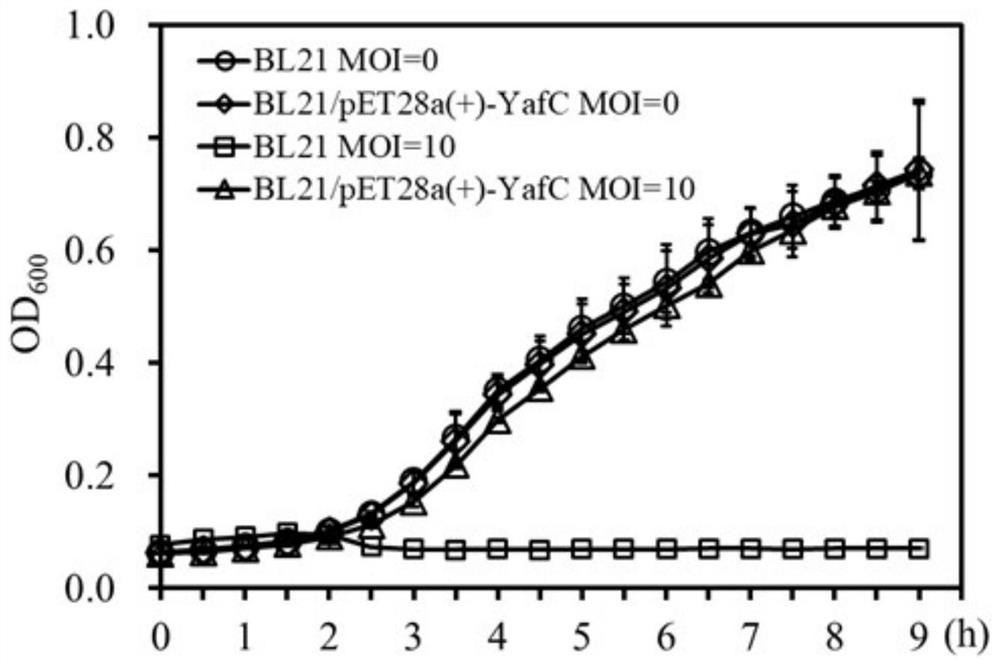

[0043] Example 2: Verification of yafC overexpression strain BL21 / pET28a(+)-YafC tolerance to phage sensitivity

[0044] Specific steps are as follows:

[0045]The wild-type strain BL21 cultivated overnight, and the yafC overexpression strain BL21 / pET28a(+)-YafC obtained in Example 1 were inoculated in fresh liquid LB medium, and cultivated at 37° C. and 180 rpm until the early logarithmic growth phase ( OD 600 = 0.6), the anti-phage ability of the yafC overexpression strain BL21 / pET28a(+)-YafC was verified by spotting assay and phage action on the bacteriostatic curves of the two strains.

[0046] Specific steps for spotting assay: inoculate wild-type Escherichia coli BL21 and yafC overexpression strain BL21 / pET28a(+)-YafC cultured overnight (16h) into fresh liquid LB culture sets, and cultivate to logarithmic growth at 37°C and 180rpm Early period (OD 600 =0.8), and then pipet 200 μL of BL21 and BL21 / pET28a(+)-YafC colonies into 3 mL of semi-solid LB medium, mix well, and...

Embodiment 3

[0049] Example 3: Application of high-efficiency anti-phage chassis cells BL21 / pET28a(+)-YafC in the process of γ-aminobutyric acid whole-cell transformation

[0050] Construction of the vector pET28a(+)-YafC-Gad: the nucleotide sequence shown in SEQ ID NO.5 was digested with SacI and NotI enzymes and connected to the recombinant plasmid pET28a(+)-YafC to obtain the recombinant plasmid pET28a(+ )-YafC-Gad; the recombinant plasmid pET28a(+)-YafC-Gad was transformed into Escherichia coli (Escherichia coli) BL21, and the transformation solution was spread on LB plates containing 100 μg / mL kana resistance, and cultured at 37°C until A single colony grows; pick a single colony to LB liquid medium containing 100 μg / mL of Kanna resistance, culture at 37°C and 200 rpm for 8-12 hours, use the gel recovery kit to extract the plasmid in the bacterial liquid, and pass the plasmid to the enzyme Cutting verification, and sent for sequencing, verification is correct as a positive transforman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com