Temperature regulating slurry for reducing firing temperature of brindled brick, brindled brick and manufacturing method of brindled brick

A technology of firing temperature and manufacturing method, which is applied in the field of spotted brick and its manufacture, and tempering paste, and can solve the problem of low firing temperature of spotted brick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

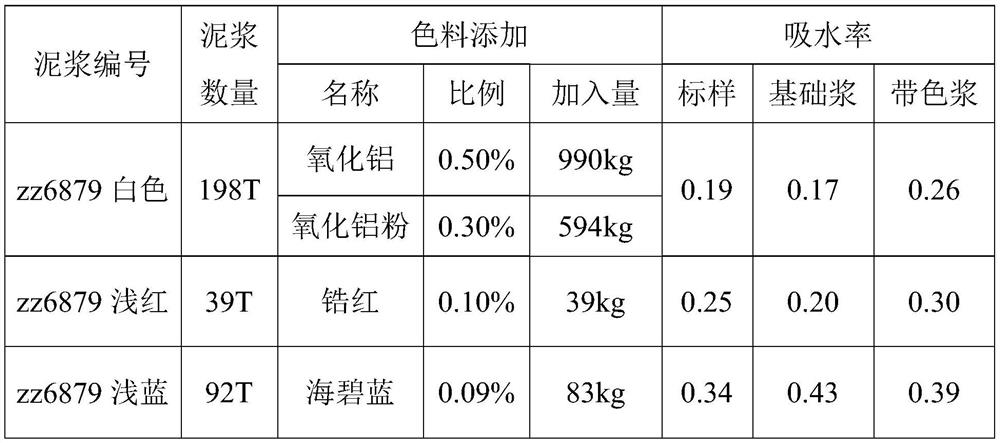

Examples

Embodiment 1

[0058] This embodiment provides a tempering paste for reducing the firing temperature of spotted bricks, wherein the raw materials of the tempering paste include:

[0059] Talc 48% to 52%; Magnesia 18% to 22%; Hui Na sand 28% to 32%.

[0060] It can be understood that in the tempering paste provided in the present invention, mud materials with good fluxing effect are used, so that the spotted bricks are affected by the added speckle particles, and after the firing temperature is increased, by adding the tempering paste , effectively reduce the firing temperature of spotted bricks, and then maintain the stability of the firing temperature of spotted bricks, improve the color repeatability between different batches of spotted bricks, ensure the continuity of production, and improve production efficiency; At the same time as the firing temperature of the bricks, the whiteness of the spotted bricks can not be affected, and the strength of the spotted bricks can be simultaneously i...

Embodiment 2

[0062] This embodiment provides a tempering paste for reducing the firing temperature of spotted bricks, which is different from the first embodiment above in that: the raw materials of the tempering paste are calculated by mass percentage, including:

[0063] Talc 50%; Magnesia 20%; Hui Na sand 30%.

[0064] It can be understood that in the tempering slurry provided in the present invention, mud materials with high aluminum content, low magnesium content and low iron content and good fluxing effect are used, so that the spotted bricks are affected by the added spotted particles, making them After the firing temperature is increased, the firing temperature of the speckled bricks can be effectively reduced by adding tempering paste, thereby maintaining the stability of the firing temperature of the speckled bricks, improving the color repeatability between different batches of speckled bricks, and ensuring The continuity of production improves production efficiency; while stabi...

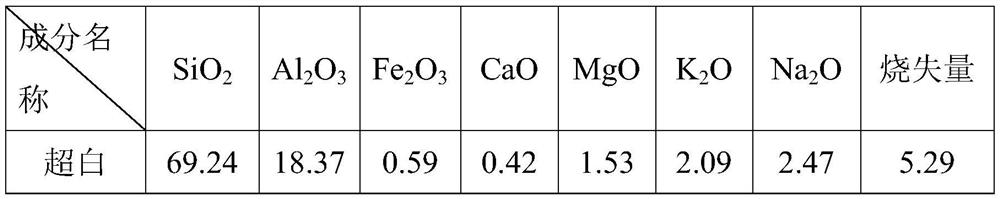

Embodiment 3

[0066] This embodiment provides a kind of tempering paste that reduces the firing temperature of spotted bricks. The chemical composition of the tempering paste is calculated by mass percentage, including:

[0067] SiO 2 60.18%; Al 2 o 3 5.96%; Fe 2 o 3 0.40%; CaO 0.76%; MgO 22.36%; K 2 O0.24%; Na 2 O 2.65%; loss on ignition 7.45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com