Ultra-high-stroke pumping anti-crack concrete suitable for cable bent tower structure and preparation method

A concrete and elevation technology, applied in the field of new inorganic non-metallic materials, can solve the problems of difficulty in realizing self-compacting and ultra-high-elevation pumping, limited effect of reducing viscosity and plastic preservation of concrete, affecting the working performance of concrete, etc., so as to reduce the risk of cracking and reduce the Adiabatic temperature rise, the effect of compensating self-shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of described anti-cracking agent comprises the following steps:

[0051] 1) Heat starch at 140-180°C for 1.5-2.5 hours for pyrolysis, then cool to room temperature,

[0052] 2) Dissolve the product of step 1) in water and stir to form a starch slurry, adjust the pH to 5.5-6.5, add α-amylase, hydrolyze at 30-38°C for 5-8 hours, then adjust the pH to 2-4 to eliminate the enzyme treatment 1h, adjust the pH to be neutral,

[0053] 3) The product obtained in step 2) is placed in a vacuum drying oven to dry and cool to obtain the hydration temperature rise control material;

[0054] 4) The calcium-magnesium composite expansion material is composed of calcium oxide expansion agent and magnesium oxide expansion agent with different activities. The calcium oxide expansion agent is mixed and ground into powder by limestone and gypsum, and then calcined at 1100-1300°C for 60-120min Finally, it can be ground with zeolite powder and fly ash to obtain a calci...

Embodiment 1

[0061] Select above-mentioned prepared anti-cracking agent and viscosity modifying material equivalent to replace cement, fly ash and slag powder, the anti-cracking concrete mix ratio prepared by the method of the present invention is: cement (C) 251kg / m 3 , fly ash (FA) 92kg / m 3 , mineral powder (BFS) 51kg / m 3 , anti-cracking agent (HME-V) 38kg / m 3 , viscosity modified material (VMM) 38kg / m 3 , gravel (G) 1002kg / m 3 , river sand (S) 756kg / m 3 , water (W) 146kg / m 3 , high-performance polycarboxylate superplasticizer (PC-A) 6.11kg / m 3 ;

Embodiment 2

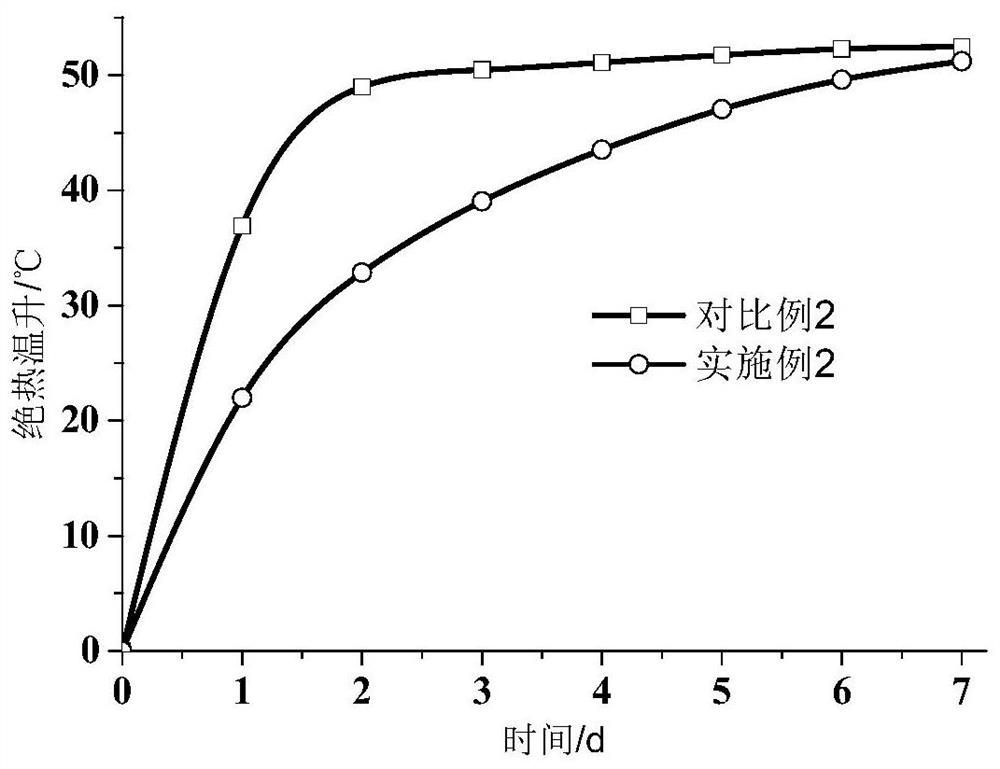

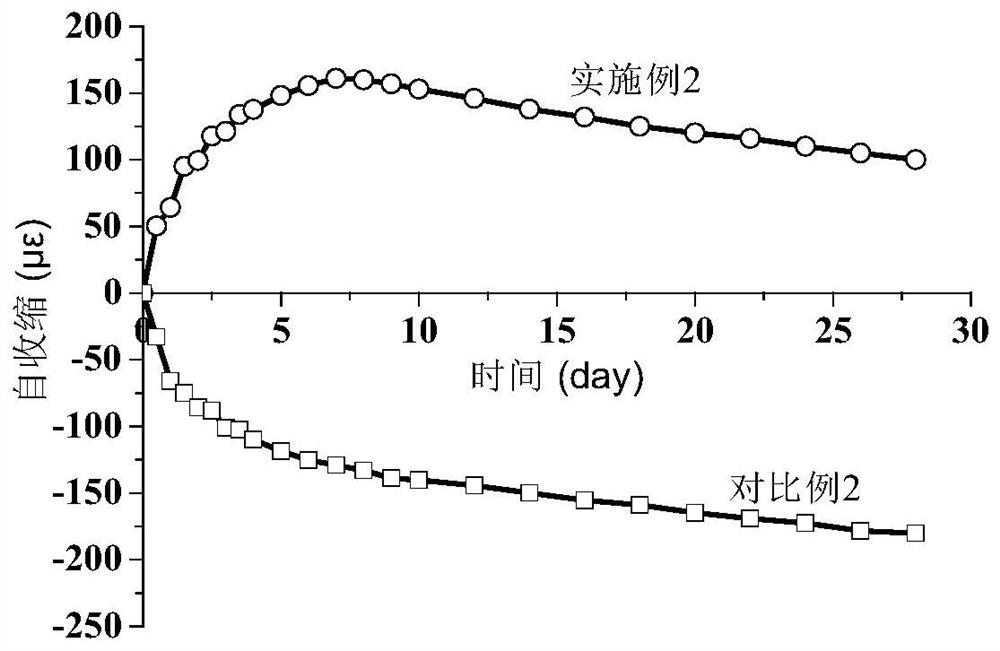

[0078] Taking raw materials by weighing table 2 to prepare C50 cable tower structure ultra-elevation pumping anti-cracking concrete is embodiment 2, and the concrete mix ratio of comparative example 2 is shown in table 2; embodiment 2 and the concrete performance and pumping of comparative example 2 gained The performance results are shown in Table 3, the mechanical properties and durability results are shown in Table 4, and the deformation performance results are shown in Table 4. figure 1 As shown, the adiabatic temperature rise results are shown in figure 2 shown.

[0079] Table 2 C50 cable tower structure ultra-elevation pumping crack-resistant concrete and comparative example 2 concrete mix ratio (unit: kg / m 3 )

[0080] serial number C FA BFS VMM HME-V S G W PC-A Comparative example 2 282 117 71 0 0 745 989 146 6.11 Example 2 251 92 51 38 38 745 989 146 6.11

[0081] Table 3 Example 2 and Comparative Example 2 C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com