A kind of reinforced mortar and preparation method thereof

A technology for strengthening mortar and cement mortar, applied in the field of cement, can solve the problems of unsatisfactory on-site construction, complicated equipment, high cost, etc., and achieve the effect of convenient and quick maintenance, easy operation and less pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] An embodiment of the present invention also provides a method for preparing the reinforced mortar as described above, which comprises the following steps:

[0038] Preparation of carbon dioxide releasing resin balls;

[0039] Prepare the cement mortar, mix carbon dioxide releasing resin balls and calcium carbonate powder into the cement mortar, stir, and obtain the reinforced mortar after a predetermined time.

[0040] When mixing, the added amount of the carbon dioxide releasing resin ball and calcium carbonate powder is in accordance with the aforementioned weight ratio. More preferably, the optimal addition amount of the carbon dioxide releasing resin ball is 7% of the weight of the cement mortar, and the optimal addition amount of the calcium carbonate powder is 6-10% of the weight of the cement mortar. More preferably, the calcium carbonate powder is the optimal addition amount. The addition amount is 10% of the weight of the cement mortar. The predetermined time...

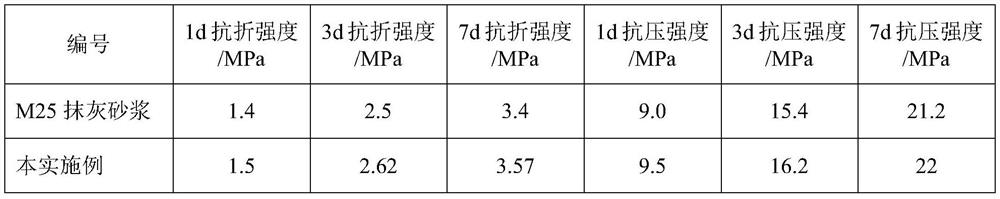

Embodiment 1

[0048] The reinforced mortar preparation steps of the present embodiment are as follows:

[0049] 1. Mix calcium bicarbonate, acetic acid and water in a weight ratio of 10:15:50 to form a mixed solution;

[0050] 2. Put 200 mesh SAP superabsorbent resin particles into the mixed solution, stir evenly, and soak. When the SAP superabsorbent resin particles expand to 0.75-1.50mm, stop soaking to form carbon dioxide releasing resin balls.

[0051] Obtain carbon dioxide releasing resin balls for use. Then, according to the predetermined addition amount actually required, the carbon dioxide releasing resin ball and the plastering mortar are mixed. The details are as follows: 3 parts of carbon dioxide releasing resin balls and 100 parts of plastering mortar are mixed, and after a predetermined time, the reinforced mortar of Example 1 is formed.

[0052] Then, the reinforced mortar obtained in Example 1 was tested for various flexural strengths, and a list was recorded.

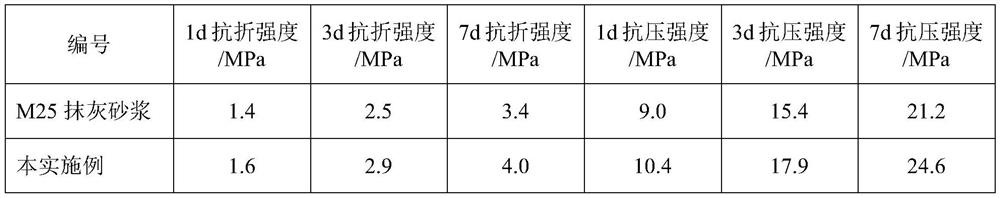

Embodiment 2

[0054] The reinforced mortar preparation steps of the present embodiment are as follows:

[0055] 1. Mix calcium bicarbonate, acetic acid and water in a weight ratio of 15:15:50 to form a mixed solution;

[0056] 2. Put 200 mesh SAP superabsorbent resin particles into the mixed solution, stir evenly, and soak. When the SAP superabsorbent resin particles expand to 0.75-1.50mm, stop soaking to form carbon dioxide releasing resin balls.

[0057] Obtain carbon dioxide releasing resin balls for use. Then, according to the predetermined addition amount actually required, the carbon dioxide releasing resin ball and the plastering mortar are mixed. The details are as follows: 5 parts of carbon dioxide releasing resin balls and 100 parts of plastering mortar are mixed, and after a predetermined time, the reinforced mortar of Example 2 is formed.

[0058] Then, various flexural strength tests were performed on the reinforced mortar obtained in Example 2, and a list was recorded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com