High-activity regenerated auxiliary cementing material based on physical ball milling and nano-modification synergistic reinforced brick-concrete powder and preparation method thereof

An auxiliary cementitious material, nano-modification technology, applied in cement production and other directions, can solve the problem of low activity of brick-mixed powder, achieve the effect of strong permeability, reduce surface cracks, and improve technical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

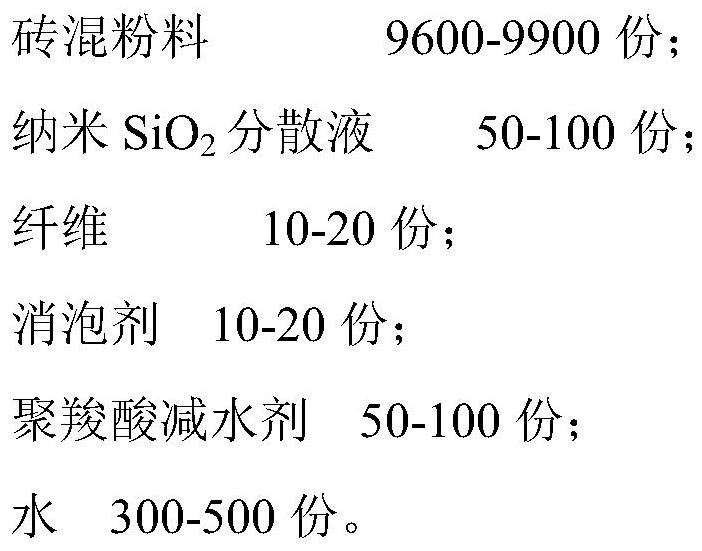

Method used

Image

Examples

Embodiment 1

[0031] 1) Take each component by weight percentage: 9900 parts of brick-concrete powder, 420 parts of composite nano-modifier;

[0032] 2) Put the brick-concrete powder and composite nano-modifier into the ball mill for 15 minutes, take it out and seal it.

[0033] The regenerated auxiliary cementitious material was obtained by the above method, and it was mixed with 30% cement to form a 20×20×20mm standard consistency cement paste test piece. After 1 day, the formwork was removed and placed in a standard curing room with a temperature of 20±2°C and a humidity of ≥95. %. After reaching the curing age, the compressive strength measured at 3 days, 7 days, and 28 days was 25.6MPa, 39.3MPa, and 70.5MPa, respectively, which was 29.3% higher than that of the cement slurry mixed with 30% unreinforced brick-concrete powder. %, 12.9% and 19.5%.

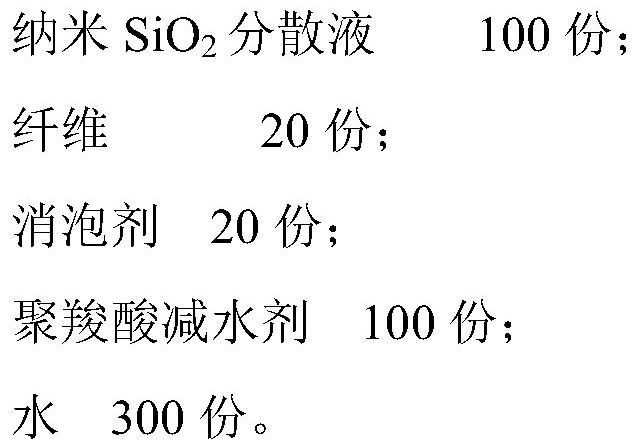

Embodiment 2

[0035] 1) Take each component by weight percentage: 9800 parts of brick-concrete powder, 530 parts of composite nano-modifier;

[0036] 2) Put the brick-concrete powder and composite nano-modifier into the ball mill for 20 minutes, take it out and seal it.

[0037] The regenerated auxiliary cementitious material was obtained by the above method, and it was mixed with 30% cement to form a 20×20×20mm standard consistency cement paste test piece. After 1 day, the formwork was removed and placed in a standard curing room with a temperature of 20±2°C and a humidity of ≥95. %. After reaching the curing age, the compressive strength measured at 3 days, 7 days, and 28 days was 26.3MPa, 40.8MPa, and 71.0MPa, respectively, which was 32.8% higher than that of the cement slurry mixed with 30% unreinforced brick-concrete powder. %, 17.2% and 20.3%.

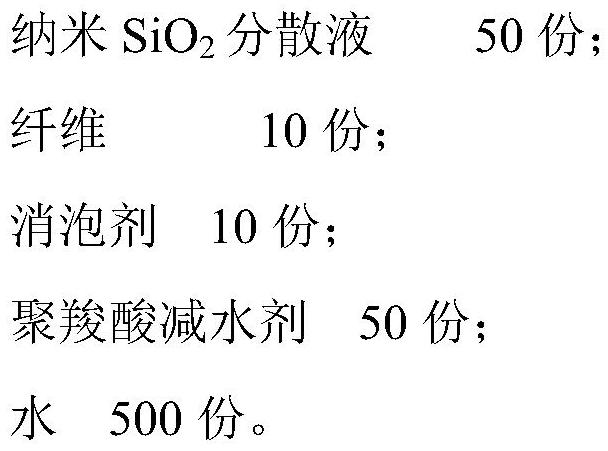

Embodiment 3

[0039] 1) Take each component by weight percentage: 9700 parts of brick-concrete powder, 640 parts of composite nano-modifier;

[0040] 2) Put the brick-concrete powder and composite nano-modifier into the ball mill for 20 minutes, take it out and seal it.

[0041] The regenerated auxiliary cementitious material was obtained by the above method, and it was mixed with 30% cement to form a 20×20×20mm standard consistency cement paste test piece. After 1 day, the formwork was removed and placed in a standard curing room with a temperature of 20±2°C and a humidity of ≥95. %. After reaching the curing age, the compressive strength measured at 3 days, 7 days, and 28 days was 26.9MPa, 41.1MPa, and 71.5MPa, respectively, which was 35.9% higher than that of the cement slurry mixed with 30% unreinforced brick-concrete powder. %, 18.1% and 21.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com