Low-loss optical fiber preform outer cladding, preparation equipment and preparation method thereof, and optical fiber

A technology of optical fiber preform and outer cladding, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increased Rayleigh scattering, large Rayleigh scattering, and affecting loss, and achieve good optical uniformity and low stress birefringence , high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

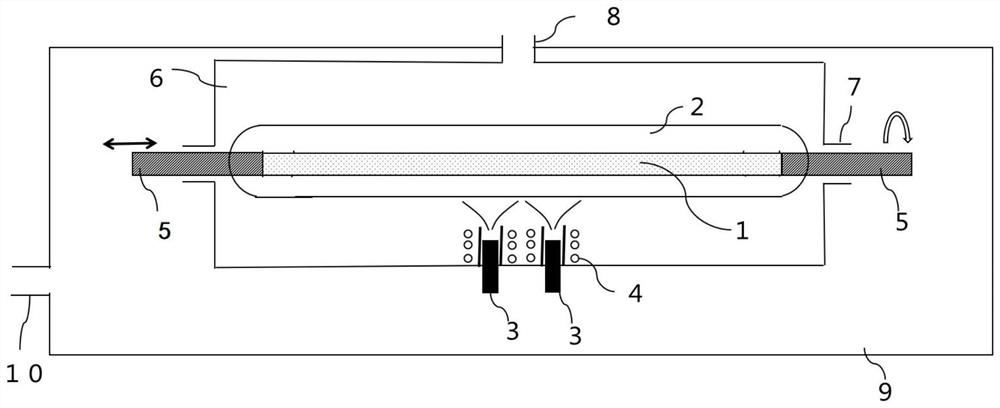

[0061] The equipment for preparing the outer coating of the optical fiber preform in the present invention includes a second deposition chamber 9, a first deposition chamber 6, a plasma generator 4, and a quartz torch 3. See figure 1 .

[0062] The second deposition chamber 9 is provided with a second chamber air inlet 10, and an ambient gas storage tank is externally connected to the second chamber air inlet 10, and a target atmosphere is formed in the second deposition chamber 9 through the input of the ambient gas.

[0063] The first deposition chamber 6 is provided inside the second deposition chamber 9, and a first deposition chamber exhaust port 8 and a first deposition chamber intake port 7 are opened on the first deposition chamber exhaust port 8. In communication with the external environment of the second deposition chamber 9, a quartz handle 5 is penetrated through the air inlet 7 of the first deposition chamber. One end of the quartz handle 5 is detachably connected to t...

Embodiment 2

[0074] Adjust the following parameters on the basis of embodiment 1, and the remaining parameters maintain the state of embodiment 1.

[0075] Plasma is used to pre-treat the surface of the core rod before the outer coating is deposited. The core rod rotation speed is 40 rpm, the left and right movement speed of the core rod is 50 mm / min; the distance between the core rod and the torch is 45 mm; the pretreatment is 2 times, and the plasma generator power is 7 kW .

[0076] After reaching the target diameter, the power of the plasma generator is gradually reduced linearly, and the power is reduced for 0.5 hours from the beginning to the time the plasma generator is turned off.

[0077] Test the outer coating of the optical fiber preform and the drawn optical fiber according to the method of Example 1.

Embodiment 3

[0079] On the basis of Embodiment 2, the plasma generator is closed while the air inlet 10 and the air outlet 8 of the second cavity are closed, and the preform is naturally cooled in the first cavity for 1 hour.

[0080] The remaining parameters remain the same as in Example 2.

[0081] Test the outer coating of the optical fiber preform and the drawn optical fiber according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com