Heavy oil railway unloading system capable of predicting unloading completion

A railway and heavy oil technology, applied in special distribution devices, packaging, distribution devices, etc., can solve problems such as waste of energy, lack of operational predictability, unfavorable safe and stable operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

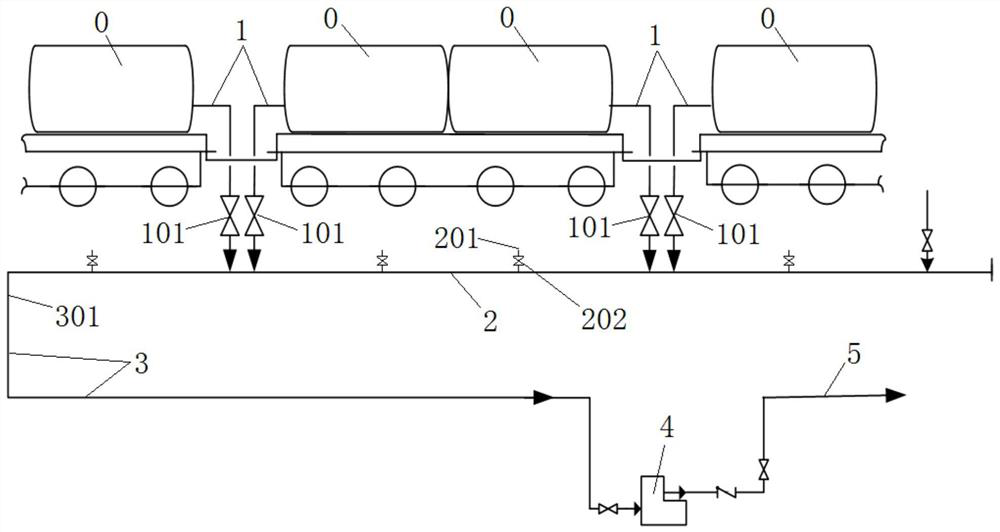

[0036] Such as figure 1 As shown, a heavy oil railway unloading system capable of predicting the completion of unloading, including a number of unloading crane pipes 1 arranged on the railway unloading platform; the top oil receiving port of the unloading crane pipe 1 is provided with a quick joint, that is, the unloading crane pipe 1 Connect with the oil unloading valve on the railway tank car 0 through a quick connector;

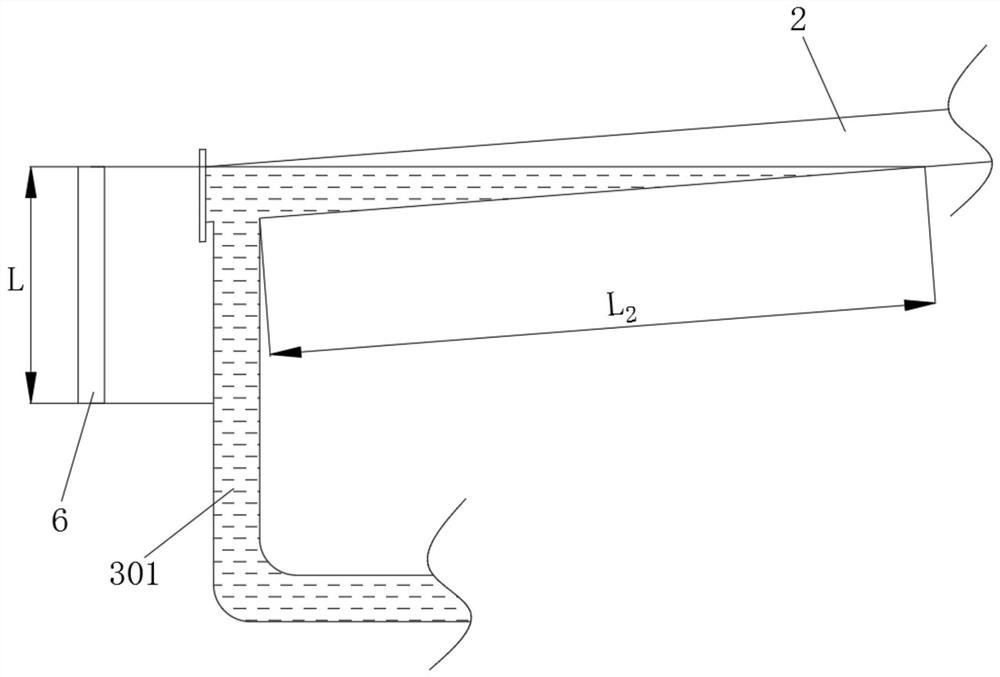

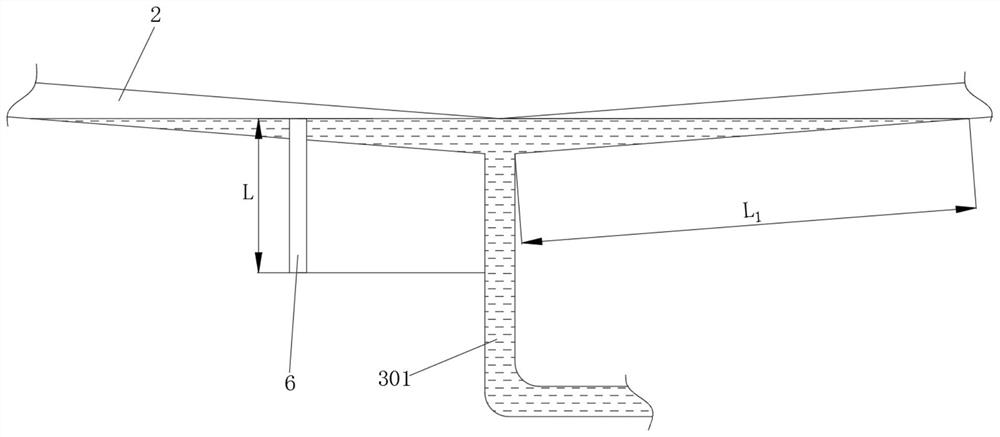

[0037] The heavy oil outlet of the unloading crane pipe 1 is connected to the oil collection pipe 2 laid along the railway unloading line and blocked at both ends. For a pipeline with a relatively large diameter on the stack, the oil manifold 2 maintains a level difference with the railway tanker 2, which acts as an oil storage container to ensure that the heavy oil in the railway tanker 2 flows to the oil manifold 2 by gravity;

[0038] The lowest point of the oil collection pipe 2 is connected to the inlet of the oil transfer pump group 4 through the oi...

Embodiment 2

[0071] On the basis of Example 1, a safety valve is installed at the outlet of each oil transfer pump to meet the requirements of relevant regulations for safety pressure relief measures for equipment and pipelines that may be overpressured to ensure safe operation;

[0072] The oil transfer pump is connected with a frequency conversion motor, that is, the oil transfer pump is driven by a frequency conversion motor to realize the frequency conversion speed regulation of the oil transfer pump;

[0073] An outlet pressure sensor is arranged on the outlet pipeline of the oil transfer pump; an inlet pressure sensor is arranged on the inlet pipeline of the oil transfer pump;

[0074] Both the inlet pressure sensor and the outlet pressure sensor are connected in communication with the controller, and the controller is electrically connected with the variable frequency motor.

[0075] When the outlet pressure of the oil transfer pump detected by the outlet pressure sensor reaches the...

Embodiment 3

[0078] On the basis of embodiment 1 or embodiment 2, the oil collecting pipe 2 is provided with some oil pouring ports 201, and the oil pouring valve 202 is set on the described oil pouring port 201; the setting of the oil pouring port 201 is convenient for collecting leaked oil Residual oil enters oil manifold 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com