Precise settling device for steel rolling machine maintenance and roller hoisting

A roll and mechanical technology, which is applied in the field of precise seating device for rolling machine maintenance roll hoisting, to achieve the effect of reducing friction, adjustable diameter range, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

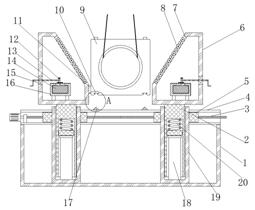

[0028] refer to Figure 1-5 , a precision seating device for roll hoisting for steel rolling machinery maintenance, comprising a dark box 1 with an opening reserved on the top and an overall rectangular parallelepiped structure, two C-shaped steel slide rails 4 with opposite openings and parallel to each other are embedded in the top of the dark box 1, and Both ends of the two C-shaped steel slide rails 4 are slidably connected with a rectangular sliding frame 5, and the middle of the two rectangular sliding frames 5 is clamped with an outer barrel 19 with an upward opening, and the inside of the outer barrel 19 is slidably connected with an extension rod 2 , the tops of the two extension rods 2 are respectively fixed with mutually symmetrical guide plates 6, and the sides of the two guide plates 6 close to the rollers are reserved with inclined surfaces, and strip-shaped holes 7 are opened near the two ends of the inclined surfaces, and the strip-shaped The holes 7 are rotate...

Embodiment 2

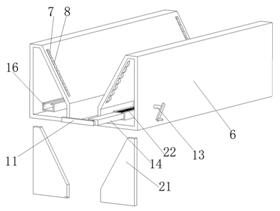

[0037] refer to Figure 1-2 , a precise seating device for roll hoisting for steel rolling machinery maintenance. Compared with Embodiment 1, this embodiment also includes two racks 22 fixed on the upper surface of the inner sliding rod 14, and two guide plates 6 opposite to each other. The side near the bottom is equipped with bearings 15, and the two bearings 15 are rotatably connected with a transmission rod 13, and the two ends of the transmission rod 13 are respectively fixed with a driving gear 12 and a rocking bar.

[0038] Wherein, the driving gear 12 and the rack 22 mesh with each other, and both ends of the guide plate 6 are clamped with side guards 21 , and both side guards 21 are provided with rectangular holes matching the section of the slide rail 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com