Automatic assembly line receiving bin

An assembly line and silo technology, which is applied in the stacking of objects, destacking of objects, loading/unloading, etc., can solve the problems of large footprint and inability to receive materials, and achieve the effect of small footprint and easy layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

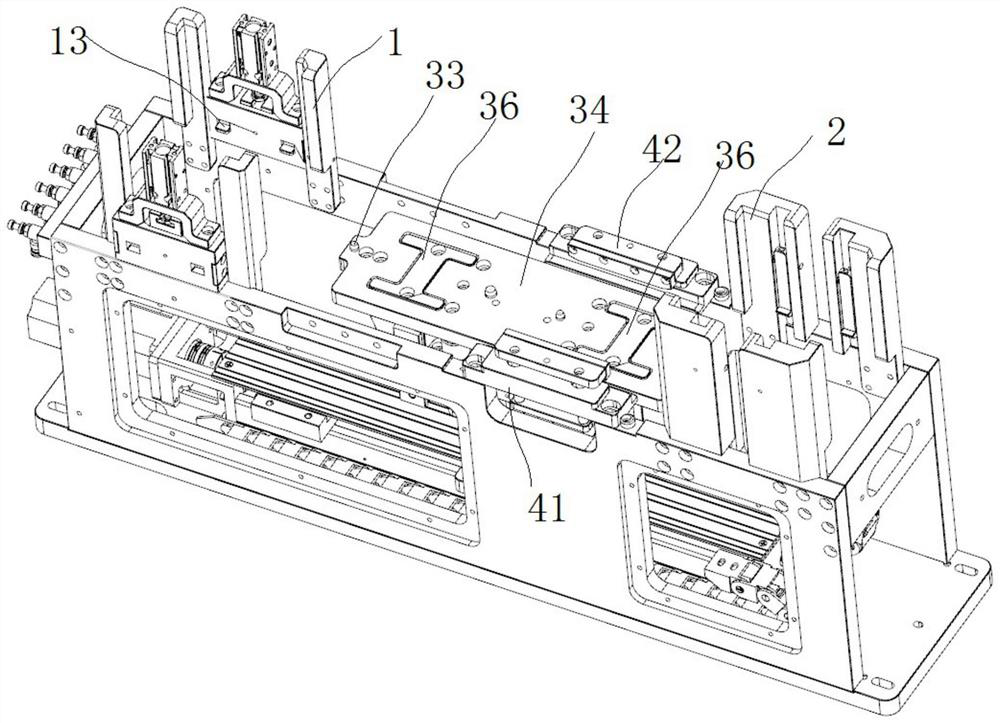

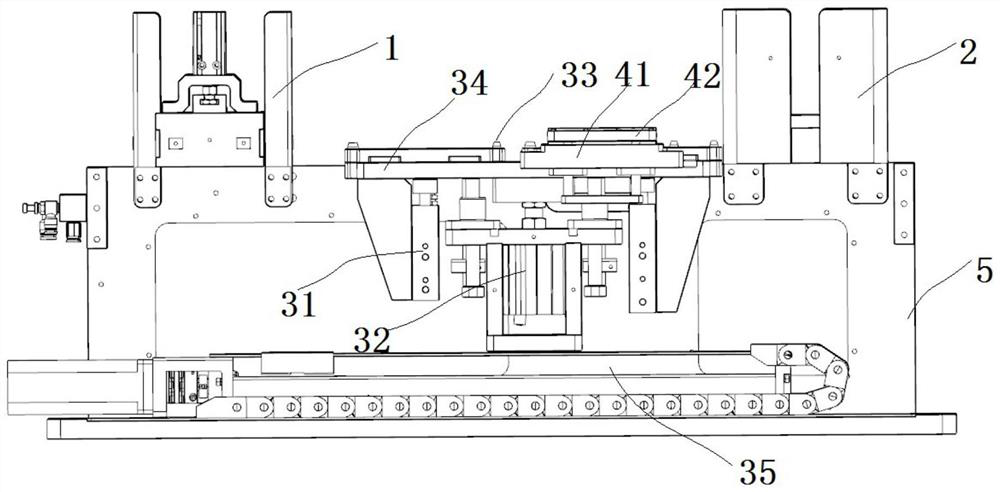

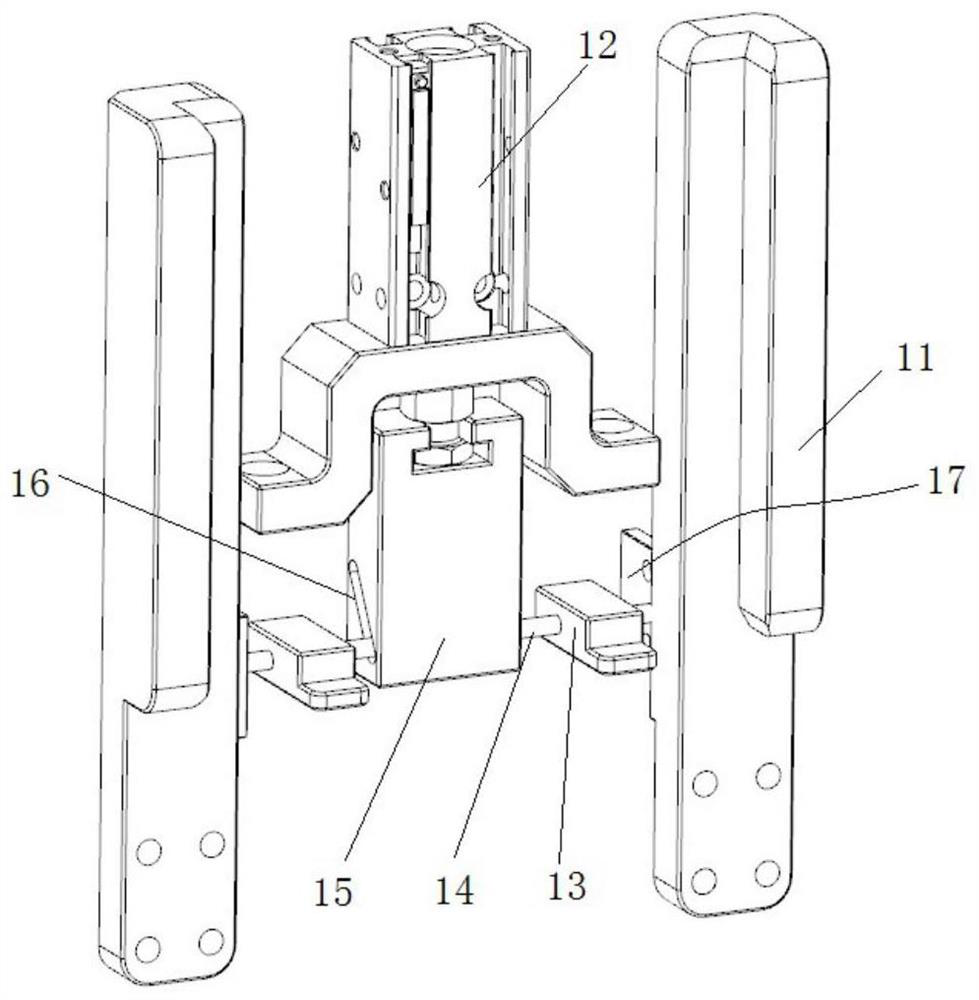

[0022] like Figure 1-4 As shown, the automatic assembly line receiving bin of the present invention includes a base 5, and a tray lowering box 1 and a tray receiving box 2 are respectively set at both ends of the base, wherein the tray lowering box 1 is used for storing empty loads. The tray, the tray receiving box 2 is used to store the tray containing the material. Among them, the trays such as Figure 5 As shown, there are pin holes on the tray and notches at the bottom of the tray.

[0023] The present invention also includes a tray moving assembly for taking out trays, loading trays and carrying trays. A tray limit mechanism 5 is arranged on the base 5, and the tray limit mechanism includes a pair of supporting plates 41 and a pair of pressing plates 42. The supporting plates 41 will hold the tray from the edge, and the pressing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com