Uniform heat conduction system for jelly sealing machine and temperature control method

A sealing machine and jelly technology, which is applied to conveyor objects, cleaning devices, loading/unloading, etc., can solve the problems of jelly deterioration, uneven heating at the connection between the sealing film and the jelly shell, and the gap between the sealing film and the jelly shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

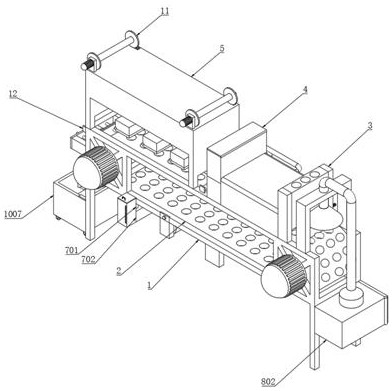

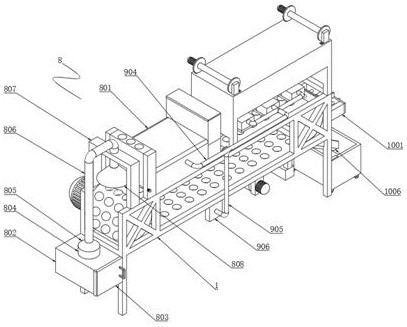

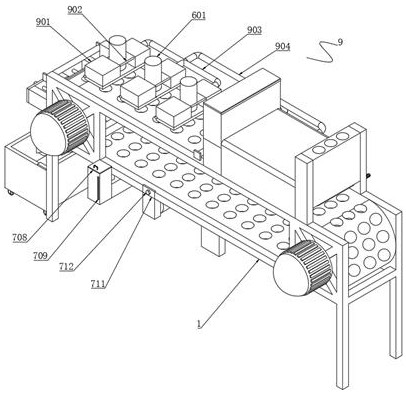

[0051] Example: such as Figure 1-8 As shown, the present invention provides a technical solution. The uniform heat conduction system of the jelly sealing machine includes a fixed frame 1. In order to facilitate the staff to carry out uniform heat conduction on the pressing plate 602 and the pressing block 617, the top of the fixed frame 1 is fixedly installed with a positioning roller 12. A conveyor belt 2 is fixedly installed on one side of the fixed frame 1, a shell block 3 is installed on the top edge of the fixed frame 1, a feeding chute 4 is installed at a position corresponding to the side of the shell block 3 on the top of the fixed frame 1, and a top edge of the fixed frame 1 A sealing block 5 is installed on the top of the sealing block 5, winding rollers 11 are installed on both sides of the top of the sealing block 5, and a heat conduction mechanism 6 is fixedly installed at the bottom of the sealing block 5.

[0052] The heat conduction mechanism 6 includes a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com