Hydraulic device for composite board production

A technology of hydraulic device and composite board, which is applied in the direction of lamination device, lamination, and layered products, etc., can solve the problems of damage to the surface of raw materials, inability to clean dust on the surface of raw materials, and inability to meet the processing of composite boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

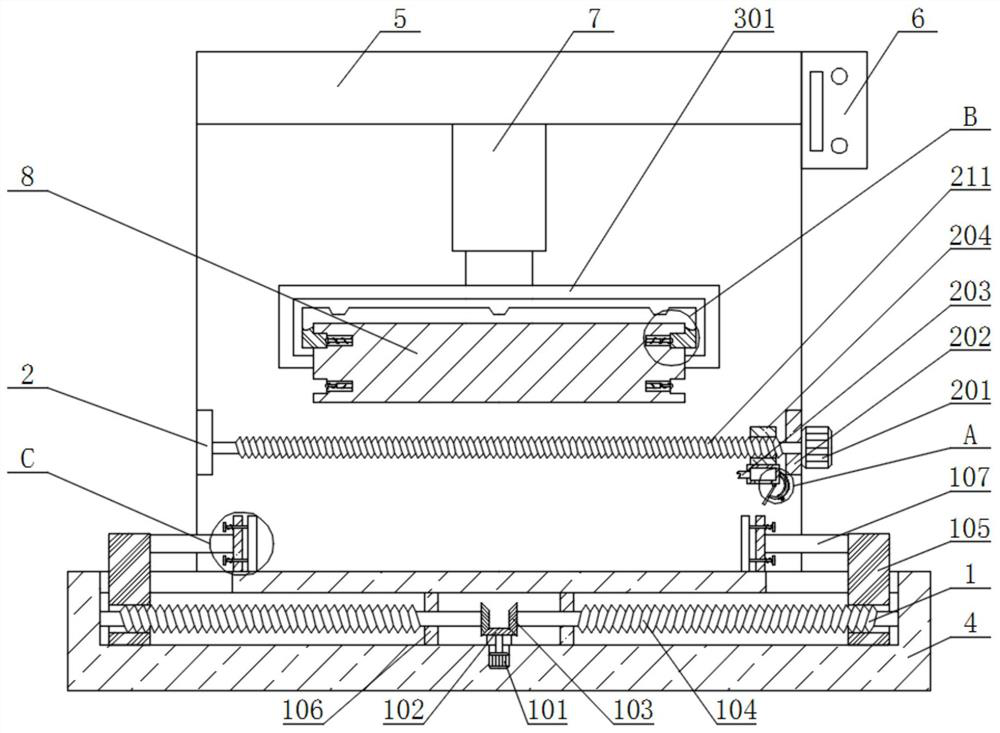

[0025] see Figure 1-5 , the present invention provides a technical solution:

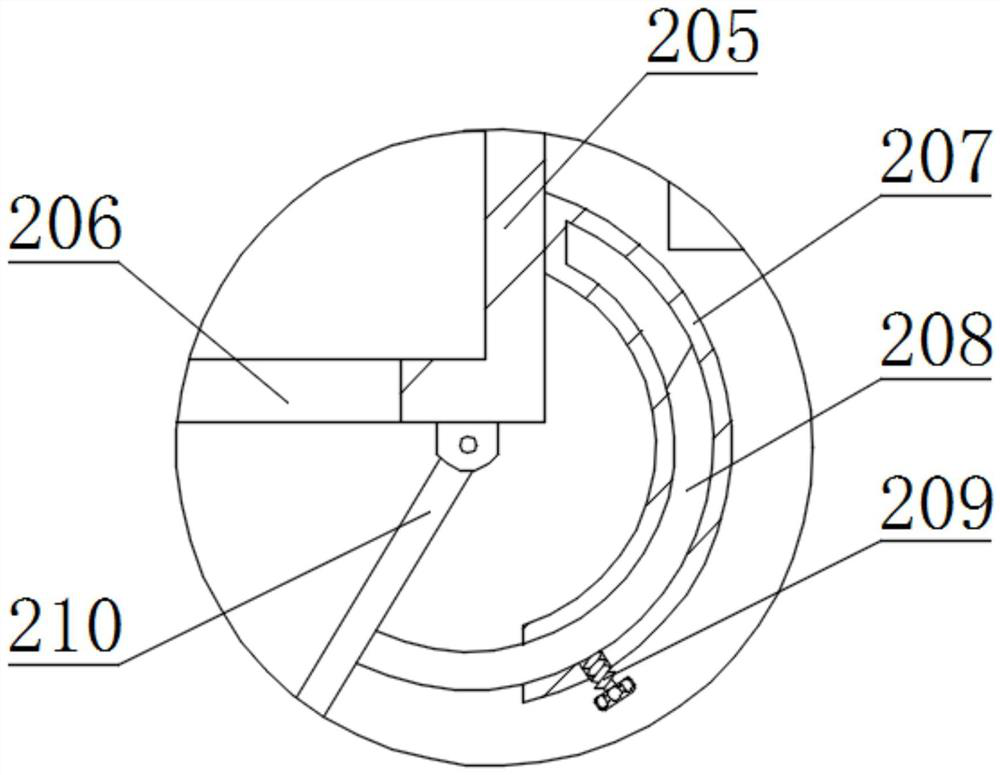

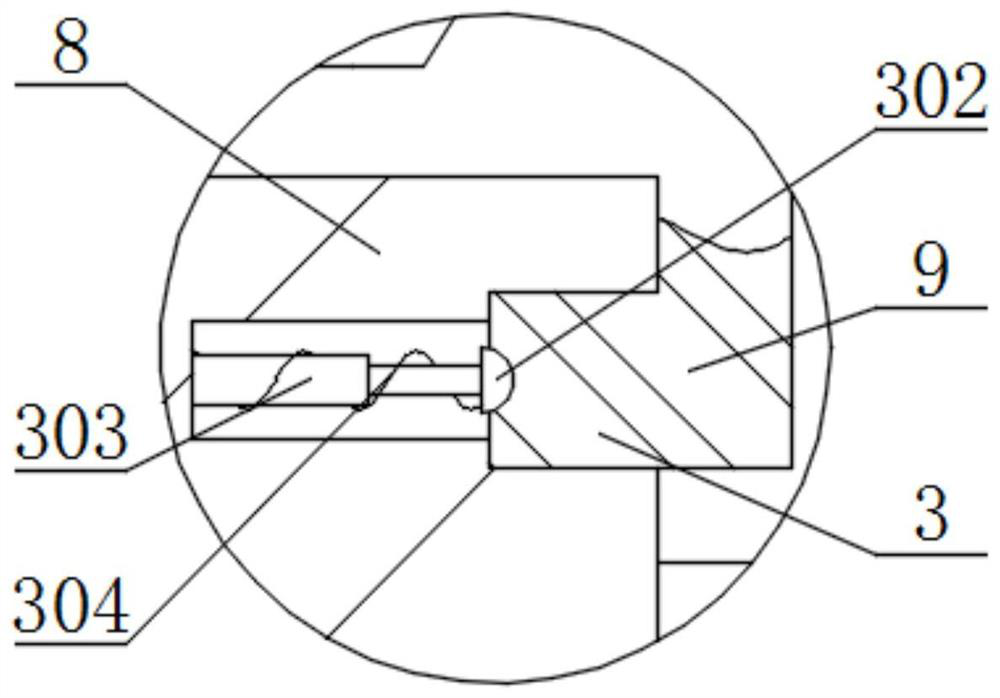

[0026] A hydraulic device for composite board production, comprising a bottom plate 4 and a connecting frame 5, the top end of the bottom plate 4 is fixedly connected with a connecting frame 5, the inner side of the top end of the connecting frame 5 is fixedly connected with a hydraulic rod 7, and the bottom end of the hydraulic rod 7 is fixedly connected with a Connecting device 3, one end of the connecting device 3 is fixedly connected with the first pressure plate 8, the inner side of the first pressure plate 8 is engaged with the second pressure plate 9, the right end of the connecting frame 5 is fixedly connected with the controller 6, and the front end of the connecting frame 5 is fixedly connected There is an air blowing device 2, and the inner side of the bottom end of the bottom plate 4 is fixedly connected with the limiter 1, and the limiter 1 includes a first motor 101, a first bevel gea...

Embodiment 2

[0029] In embodiment 2, the same parts as in embodiment 1 will not be repeated. The difference is that when the corrugated composite board needs to be pressed, the staff takes off the second press plate 9 located on the upper side of the first press plate 8 , and then placed and engaged with the chuck 302 on the lower side of the first press plate 8, so as to realize the pressing of the raw material through the second press plate 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com