Pre-tightening force adjusting mechanism of double-nut ball screw and double-nut ball screw

A technology of pre-tightening force adjustment and ball screw, which is applied to mechanical equipment, belts/chains/gears, transmission devices, etc. It can solve problems such as unsmooth operation, uncontrollable pressing force of pre-tightening blocks, and small contact surface. It achieves the effect of simple and reliable adjustment of pretightening force, avoiding stress concentration and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

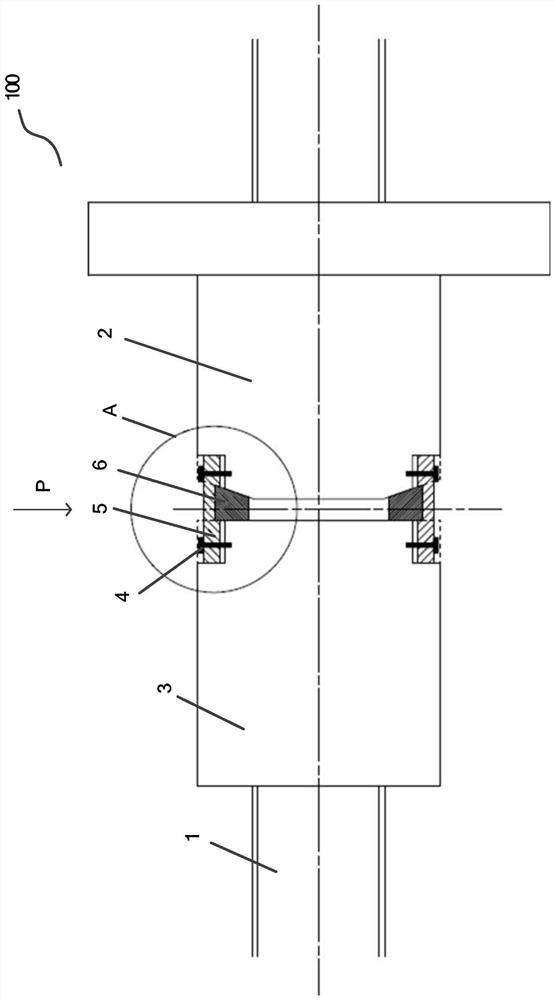

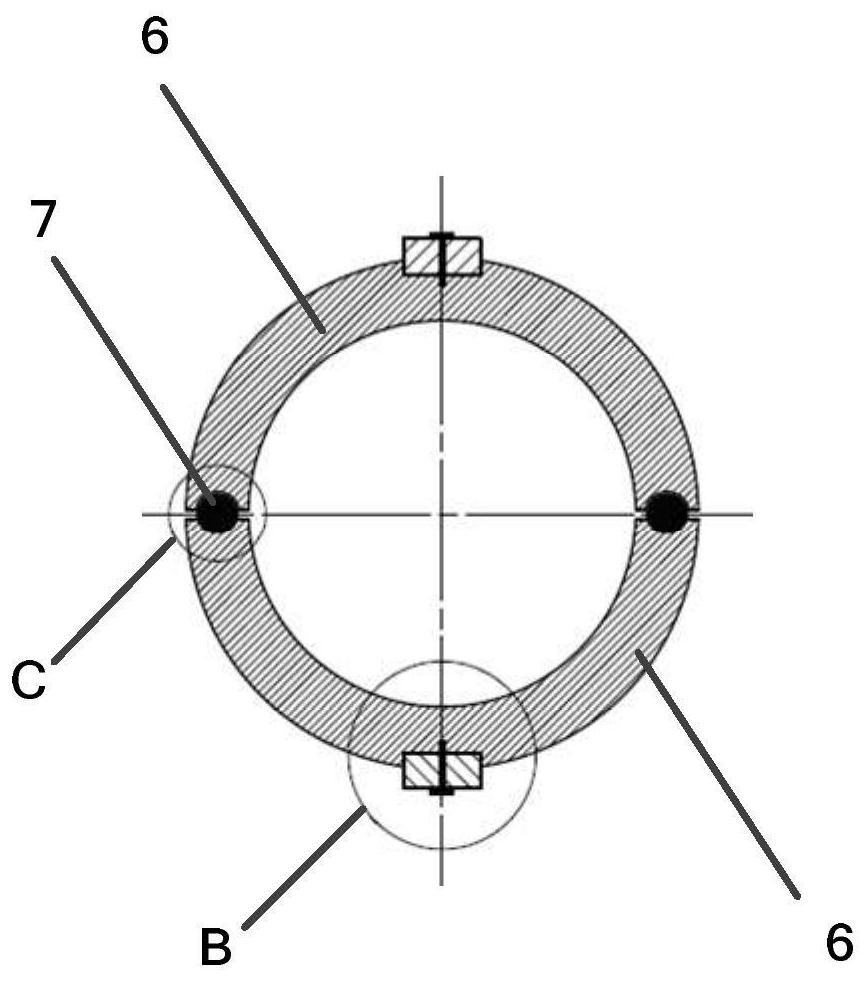

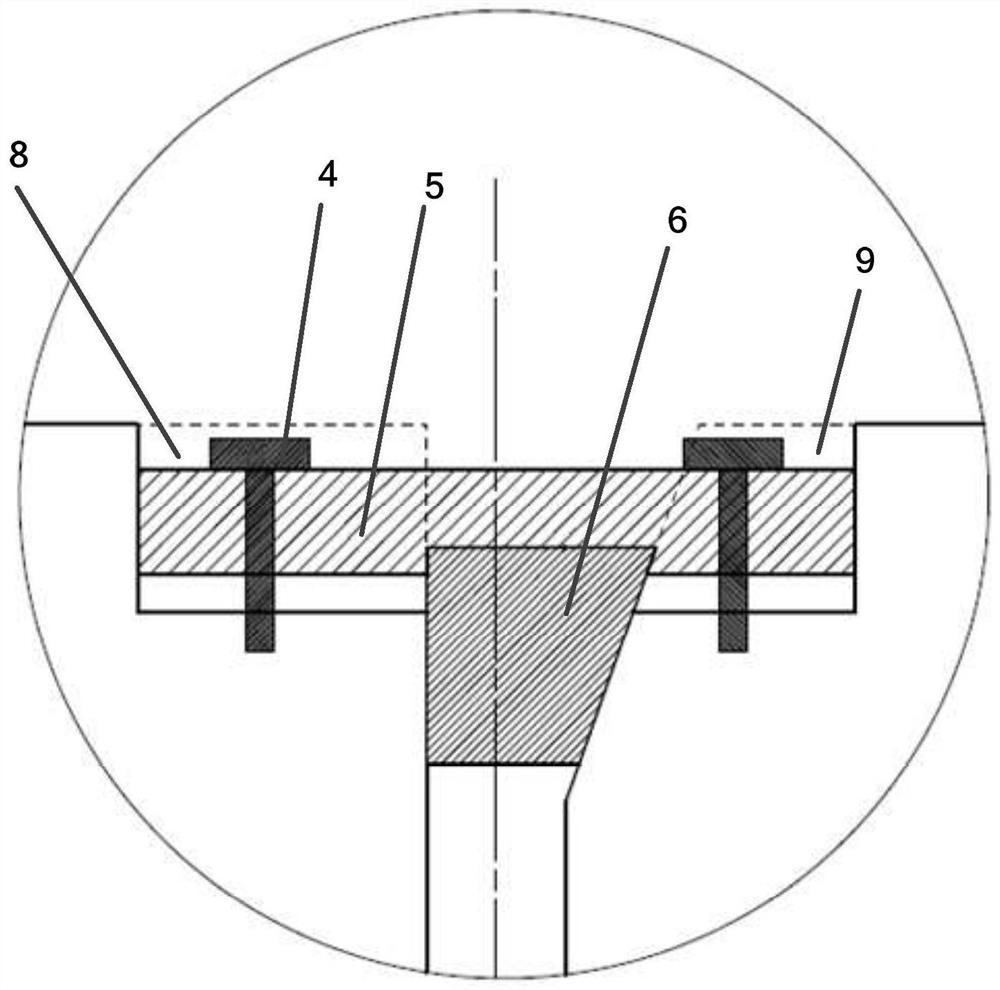

[0045] First, the double-nut ball screw according to the first embodiment of the present invention will be described. figure 1 It is a schematic diagram which shows the basic structure of the double nut ball screw which concerns on 1st Embodiment of this invention. like figure 1 As shown, the double-nut ball screw 100 mainly includes a screw shaft 1, a main nut 2 and an auxiliary nut 3 sleeved on the screw shaft 1, and a main nut 2, an auxiliary nut 3 and a screw shaft 1 arranged between the main nut 2 and the auxiliary nut 3. Multiple balls not shown.

[0046] In order to adjust the preload force of the double nut ball screw 100, a preload force adjustment mechanism is provided. The pre-tightening force adjustment mechanism of this embodiment does not need to replace the steel balls during the pre-compression adjustment process, and the pre-tightening force can be adjusted by directly adjusting the gap between the main nut and the auxiliary nut by using the feeding mechanis...

no. 2 Embodiment approach

[0063] Next, refer to Figure 7 and Figure 8 A double nut ball screw according to a second embodiment of the present invention will be described. Figure 7 It is a figure which shows the basic structure of the double nut ball screw of 2nd Embodiment of this invention, Figure 8 Yes Figure 7 Sectional view of the W section.

[0064] In the second embodiment, as in the first embodiment, the preload can be adjusted by directly adjusting the gap (relative axial distance) between the main nut and the auxiliary nut by using the feed mechanism without replacing the steel balls during the adjustment of the preload. Here, about the same structure as 1st Embodiment, the same code|symbol is attached|subjected and description is abbreviate|omitted.

[0065] In the second embodiment, as the preload adjustment mechanism of the double nut ball screw, such as Figure 7 , Figure 8 As shown, a threaded portion 10 is provided at the end of the sub nut 3 opposite to the main nut 2 . In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com