Production process of damping, noise-reducing and sound-insulating pad

A production process and sound insulation pad technology, which is applied in the field of shock absorption and noise reduction sound insulation pad production process, can solve the problems of poor compactness, increased material cost, multi-space, etc., and achieve excellent sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

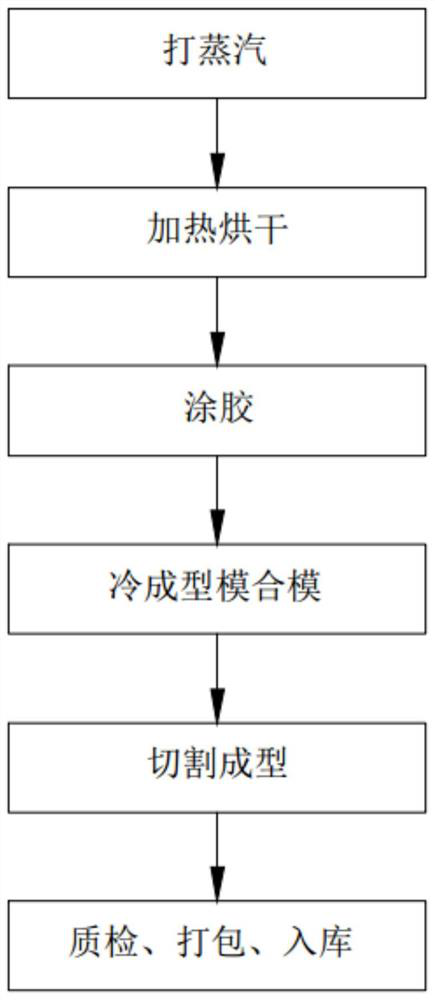

[0034] Such as figure 1 Shown, a kind of production technology of shock-absorbing and noise-reducing sound-insulating pad, comprises the following steps:

[0035] (1) Cut the sound-proof base material into a section by cutting machine and lay it in the steam mold, close the steam mold, inject the steam in the steam machine into the sound-proof base material through the steam mold, and control the pressure of the steam machine to 32MPa, steam The heating temperature of the mold is controlled at 236°C, and the heating time is kept at 35s;

[0036] (2) The sound-insulating base material that has been steamed in step (1) is grabbed by the robot and placed in the drying and gluing integrated machine. After drying and gluing, it is discharged from the drying and gluing integrated machine. The manipulator at one end of the feed port grabs and places it in the cold forming mold. The sound insulation base material in the cold forming mold includes two layers of the same sound insulati...

Embodiment 2

[0045] A production process of a shock-absorbing and noise-reducing sound-insulating pad, comprising the steps of:

[0046] (1) Cut the sound insulation substrate into a section by cutting machine and lay it in the steam mold, close the steam mold, inject the steam in the steam engine into the sound insulation substrate through the steam mold, and control the pressure of the steam engine to 35MPa, steam The heating temperature of the mold is controlled at 240°C, and the heating time is kept at 30s;

[0047] (2) The sound-insulating base material that has been steamed in step (1) is grabbed by the robot and placed in the drying and gluing integrated machine. After drying and gluing, it is discharged from the drying and gluing integrated machine. The manipulator at one end of the feed port grabs and places it in the cold forming mold. The sound insulation base material in the cold forming mold includes two layers of the same sound insulation base material. Both layers of sound i...

Embodiment 3

[0056] A production process of a shock-absorbing and noise-reducing sound-insulating pad, comprising the steps of:

[0057] (1) Cut the sound-proof base material into a section by cutting machine and lay it in the steam mold, close the steam mold, inject the steam in the steam machine into the sound-proof base material through the steam mold, and control the pressure of the steam machine to 38MPa, steam The heating temperature of the mold is controlled at 45°C, and the heating time is kept at 25s;

[0058] (2) The sound-insulating base material that has been steamed in step (1) is grabbed by the robot and placed in the drying and gluing integrated machine. After drying and gluing, it is discharged from the drying and gluing integrated machine. The manipulator at one end of the feed port grabs and places it in the cold forming mold. The sound insulation base material in the cold forming mold includes two layers of the same sound insulation base material. Both layers of sound in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com