Auxiliary device for manufacturing direct-current motor controller shell and manufacturing method thereof

A technology of DC motors and auxiliary devices, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as welding position and angle deviation, affecting installation, etc., to ensure stability, ensure structural stability, and be convenient and simple to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

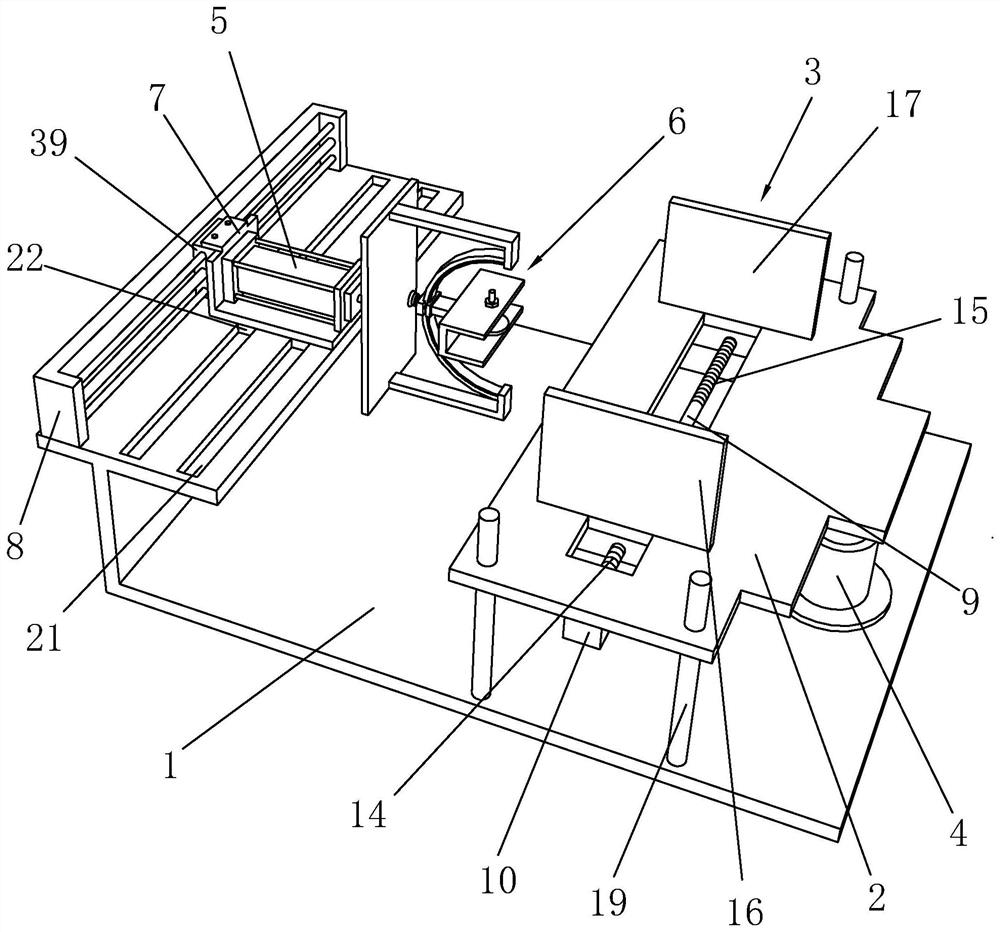

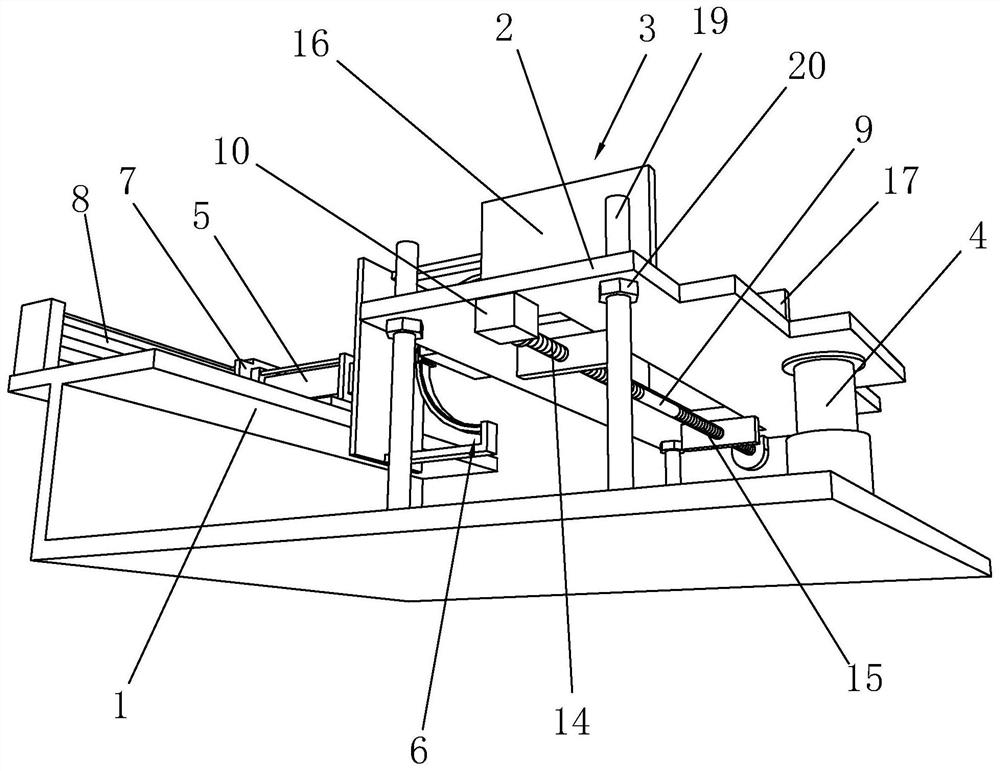

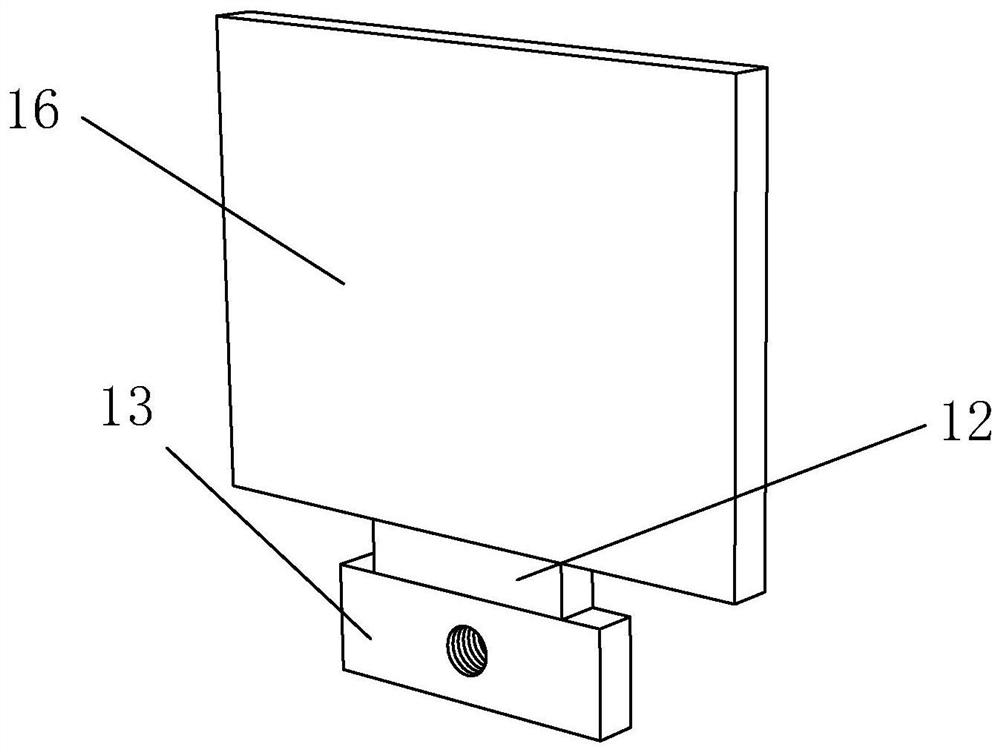

[0045] Such as Figure 1 to Figure 8 As shown, it is an auxiliary device for the manufacture of a DC motor controller housing of the present invention, including a support frame 1 and a workbench 2. A clamping assembly 3 is arranged on the workbench 2, and the bottom surface of the workbench 2 and the lifting column 4 Connected, the lifting column 4 is fixed on the support frame 1, the top of the support frame 1 is provided with a push cylinder 5, the end of the piston rod of the push cylinder 5 is connected with an angle adjustment assembly 6, and the push cylinder 5 is connected to the rodless cylinder through the bracket 7 The sliders 39 of 8 are connected, and the rodless cylinder 8 is fixed on the top of the support frame 1; the housing body 37 can be clamped and limited by the clamping assembly 3 to ensure that the housing body 37 is placed firmly on the workbench 2 Therefore, it is convenient for subsequent position adjustment and welding operations, and the lifting col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com