Production system capable of increasing coating layer thickness by pre-wetting surface and coating method

A technology of coating thickness and production system, which is applied to the device and coating of the surface coating liquid, and can solve the problems of coating accumulation, fluidity decline, eddy current formation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

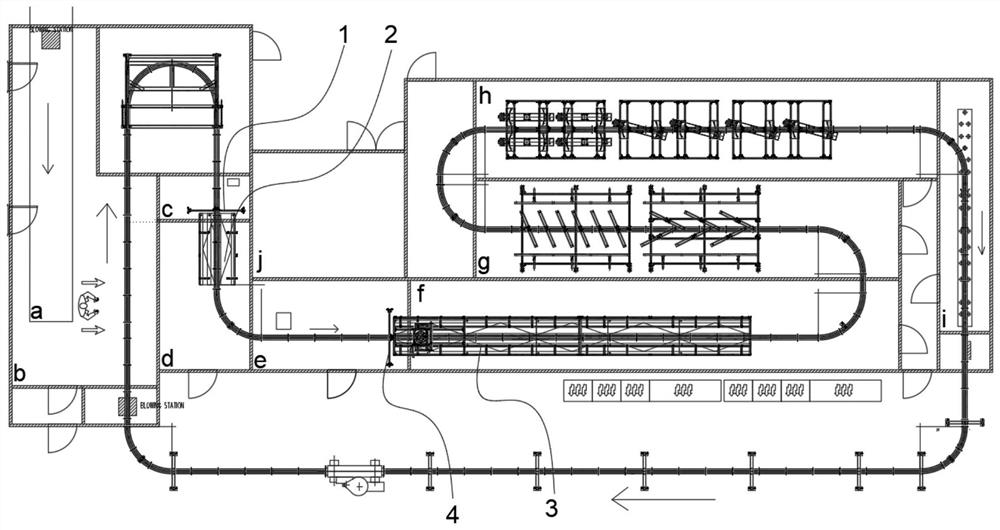

[0030] like figure 1 As shown, a production system for increasing coating thickness through surface prewetting includes a loading room for placing coated products on a conveyor belt, a first coating area, a first drip drying area, a second coating area, The second drip dry area, curing area; the above-mentioned areas are sequentially connected by a conveyor belt; the first coating machine and the second coating machine are respectively arranged in the first coating area and the second coating area; the first dripping The dry zone and the second drip dry zone are used for dripping and leveling of the coated product; the curing zone can completely dry the coating on the coated product; the coating product conveyor belt is set in the feeding room.

[0031] In this example, if figure 1 As shown, the curing area includes a heat drying room, an ultraviolet light curing area, and a product cooling area, which are sequentially connected by a conveyor belt, and the heat drying room is...

Embodiment 2

[0038] A kind of coating method that improves coating thickness by surface prewetting, comprises the steps:

[0039] A. Use a density of 0.850g / cm in the first coating area c 3 , in which 30% of photocurable resin and 70% of isopropanol are used to pre-wet the coated products;

[0040] B. Place the coated product that is pre-wet coated in step A in the first drip-drying area d to drip-dry and level the pre-wet coating. The drip-drying and leveling time is 5 minutes, and the temperature in the drip-drying area is set The temperature is 22°C, and the humidity is set to 40% RH to form a uniform and flat pre-wet coating;

[0041] C. In the second coating area e, the coating product obtained in step B has a use density of 0.890g / cm 3 , in which 45% photocurable resin and 55% isopropanol are used for high-thickness coating on the pre-wet coating;

[0042] D. Place the coated product with high-density coating in step C in the second drip-drying zone f to drip-dry and level the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com