Automatic wrinkling machine for double-layer mattress foxing

A technology of mattresses and skirts, which is applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control devices, etc., can solve the problems of high production cost, multi-process, complex production process, etc., and achieve high production efficiency, uniform wrinkling, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] see Figure 1-4 , the present invention provides a technical solution: an automatic wrinkling machine for double-layer mattress surrounds, comprising: a discharge device 1, the discharge device 1 is composed of a main frame 9 and a discharge rack, and the discharge rack is installed on the side of the main frame 9 On one side, the top of the main frame 9 is equipped with a cloth feeding device 2, and the middle part of the main frame 9 is equipped with a sewing head 6. The sewing head 6 is provided with a wrinkling device 5, a traction device 7 and a machine head presser foot 8, and the wrinkling device 5 is installed on one side of the sewing machine head 6, and the main shaft 19 of the wrinkling device 5 is connected with the rotating shaft of the sewing machine head 6 by a belt, so that the wrinkling device 5 and the sewing machine head 6 always keep synchronous rotation;

[0023] The top of the main frame 9 is symmetrically installed with a limit rod near the side o...

Embodiment 2

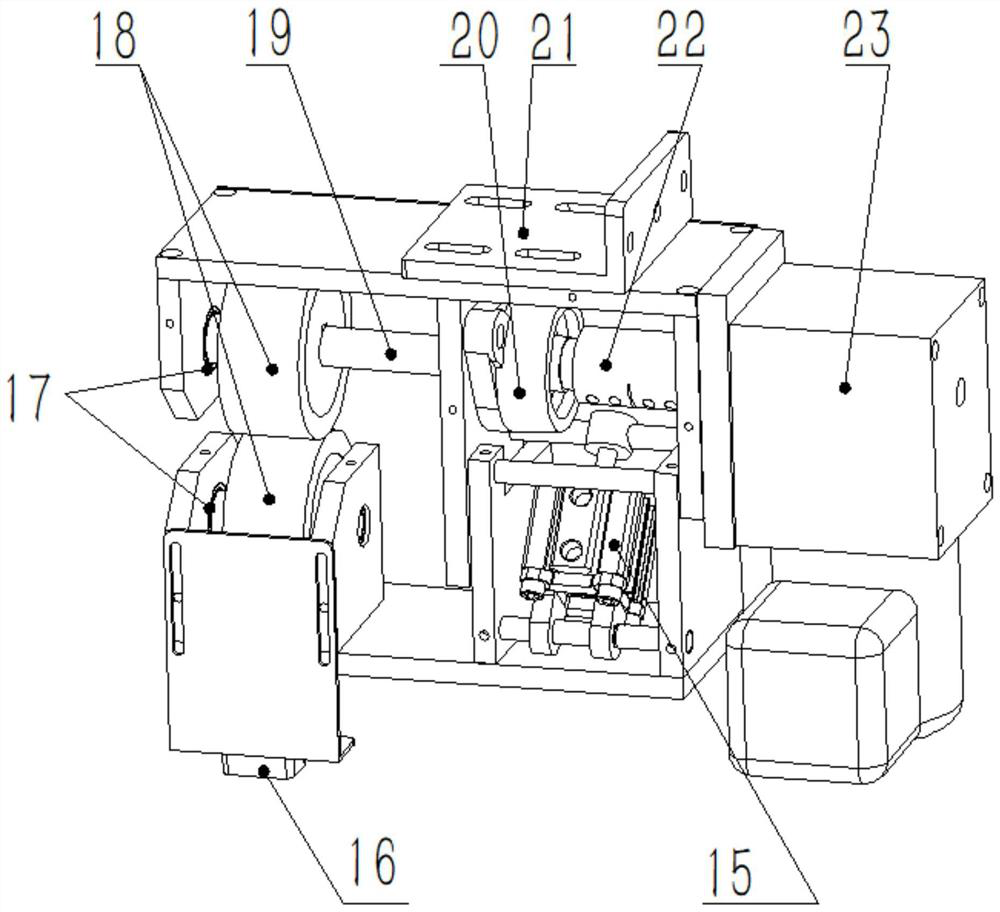

[0028] further improved, such as Figure 3-4 Shown: cloth feeding device 2 comprises fixed frame, motor two 23, cylinder 15, main shaft 19, and motor two 23 is installed on the side wall of fixed frame and the power output end of motor two 23 extends to the inner side of fixed frame and is connected with main shaft 19 connection, bearing housing 20 and shaft coupling 22 are installed on the main shaft 19, cylinder 15 is also rotatably connected in the fixed frame, a photoelectric sensor 16 is installed on the bottom side of the fixed frame, and a mounting plate 21 is arranged on the top of the fixed frame and It is connected with the main frame 9 through the mounting plate 21 . The inner side of the fixed frame is provided with two symmetrical pressure wheels 18, one of which is connected to the main shaft 19, and the other pressure wheel 18 is connected to the inner side of the fixed frame by a connecting shaft. Bearings are arranged between the connecting shaft and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com