Flue gas dust removal equipment for atmospheric pollution control

A technology of dust removal equipment and flue gas, which is applied in the direction of dispersed particle filtration, combined device, filtration and separation, etc., can solve the problems of reducing the speed of flue gas emission and the speed of flue gas, and achieve the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

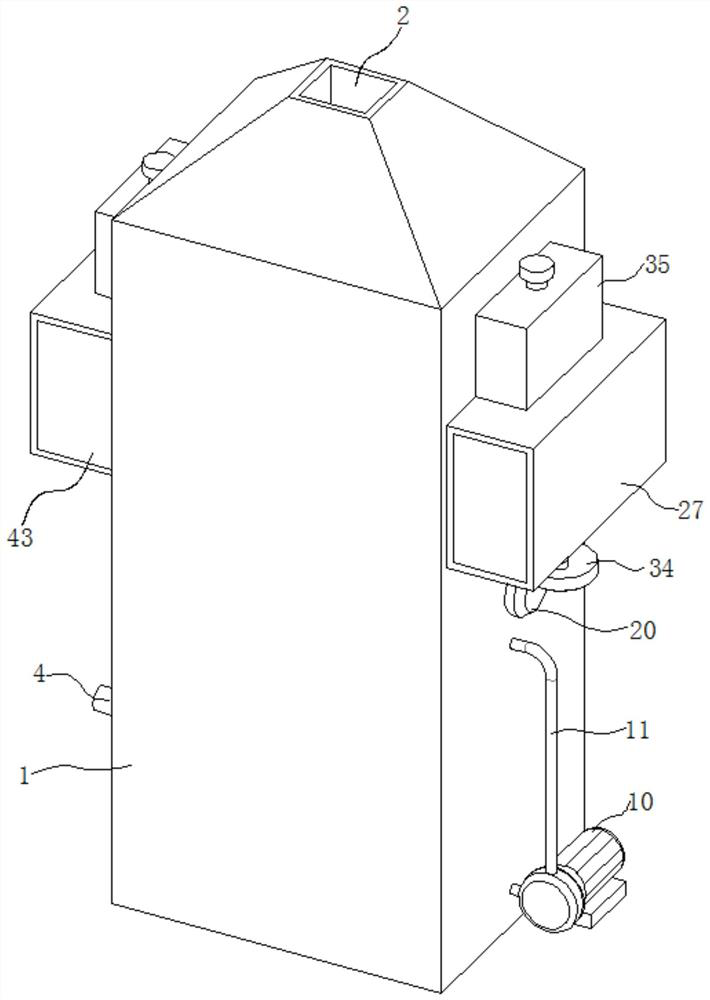

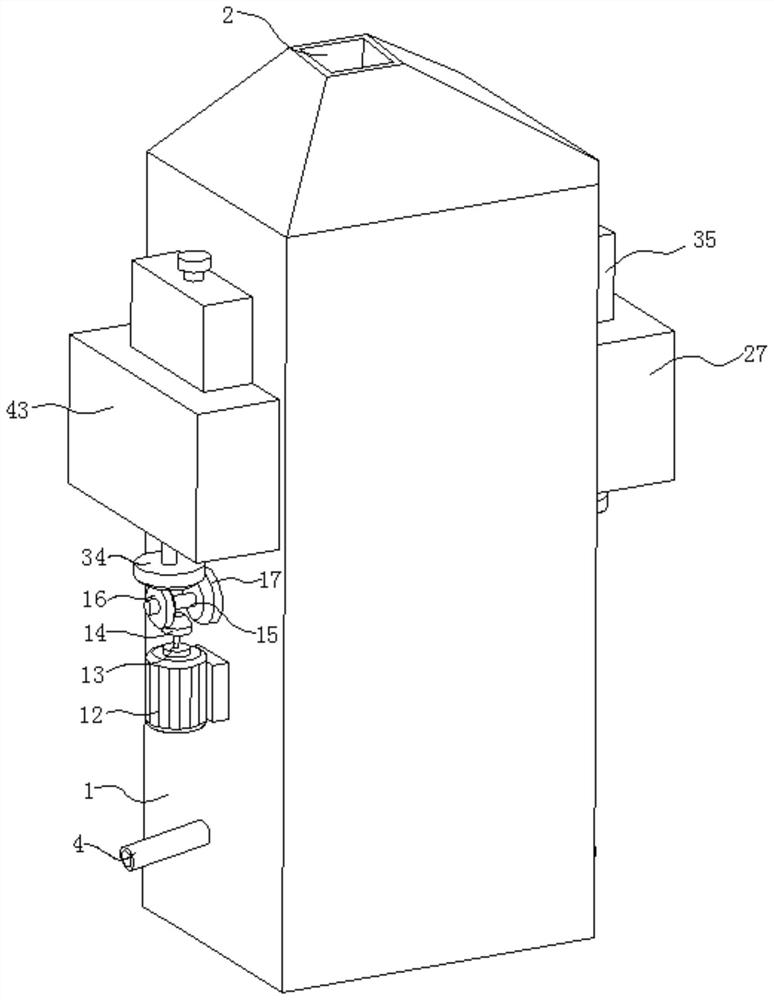

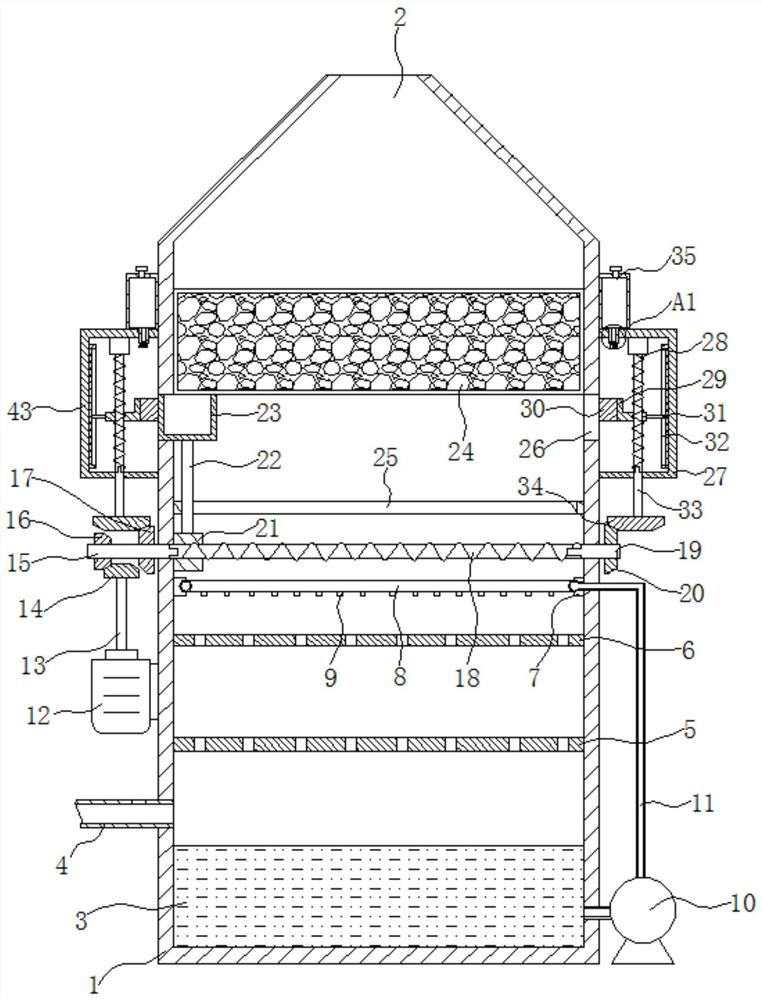

[0027] refer to Figure 1-9 , a flue gas dedusting device for air pollution prevention and control, comprising a treatment box 1, the top of the treatment box 1 is provided with an air outlet 2, the function of the air outlet 2 is to discharge the flue gas after dust removal, and the inner bottom of the treatment box 1 is placed with The liquid medicine layer 3 is connected with an air intake pipe 4 on the treatment box 1. The function of the air intake pipe 4 is to introduce the flue gas after heat exchange and cooling into the treatment box 1. Connected with a first perforated plate 5, the function of the first perforated plate 5 is to disperse the smoke, so that the smoke is evenly in contact with the second perforated plate 6, the first perforated plate 5 is located above the intake pipe 4, and the processing The second perforated plate 6 is connected in the case 1, and the effect of the second perforated plate 6 is to disperse the liquid medicine sprayed by the spraying m...

Embodiment 2

[0034] After the power mechanism is powered on, it drives the second rotating shaft 15 to rotate, and the second rotating shaft 15 drives the first reciprocating screw 18 to rotate. The first moving block 21 drives the scraper 23 to reciprocate in the horizontal direction through the support rod 22. When the foam bonded to the lower surface of the filler 24 is scraped off, due to the certain viscosity of the foam, when the scraper 23 scrapes off the foam bonded to the lower surface of the filler 24, the foam adhered to both sides of the scraper 23 will More and more, when the scraper 23 scrapes off the foam on the lower surface of the filler 24, the foam adhering to both sides of the scraper 23 adheres to the lower surface of the filler 24 again, again covering the air intake gap on the lower surface of the filler 24. , therefore, referring to Figure 1-9 , as another preferred embodiment of the present invention, on the basis of embodiment 1, both sides of processing box 1 ar...

Embodiment 3

[0038] When the foam on the side of the scraper 23 was adsorbed by the elastic block 30, because the foam remover on the elastic block 30 was limited, after a period of time, the foam remover on the elastic block 30 gradually decreased until completely consumed, and the elasticity When the block 30 cannot absorb the foam on the side of the scraper 23, it is necessary to add a foam remover, refer to Figure 1-9 On the basis of Embodiment 2, the upper end of the first box body 27 is communicated with the first medicine dispensing mechanism. Two medicine dispensing mechanisms, the effect of the second medicine dispensing mechanism is to add foam eliminator for the second wiping mechanism, the first medicine dispensing mechanism is identical in structure with the second medicine dispensing mechanism, the first medicine dispensing mechanism comprises medicine storage box 35, medicine storage The function of the box 35 is to store the foam eliminating agent, and the medicine storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com