Environment-friendly and energy-saving rapid cooler and rapid cooling method for smoke

An environment-friendly, energy-saving, quencher technology, applied in combustion methods, climate sustainability, greenhouse gas reduction, etc., to achieve good cooling effect, smooth flue gas flow, and easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

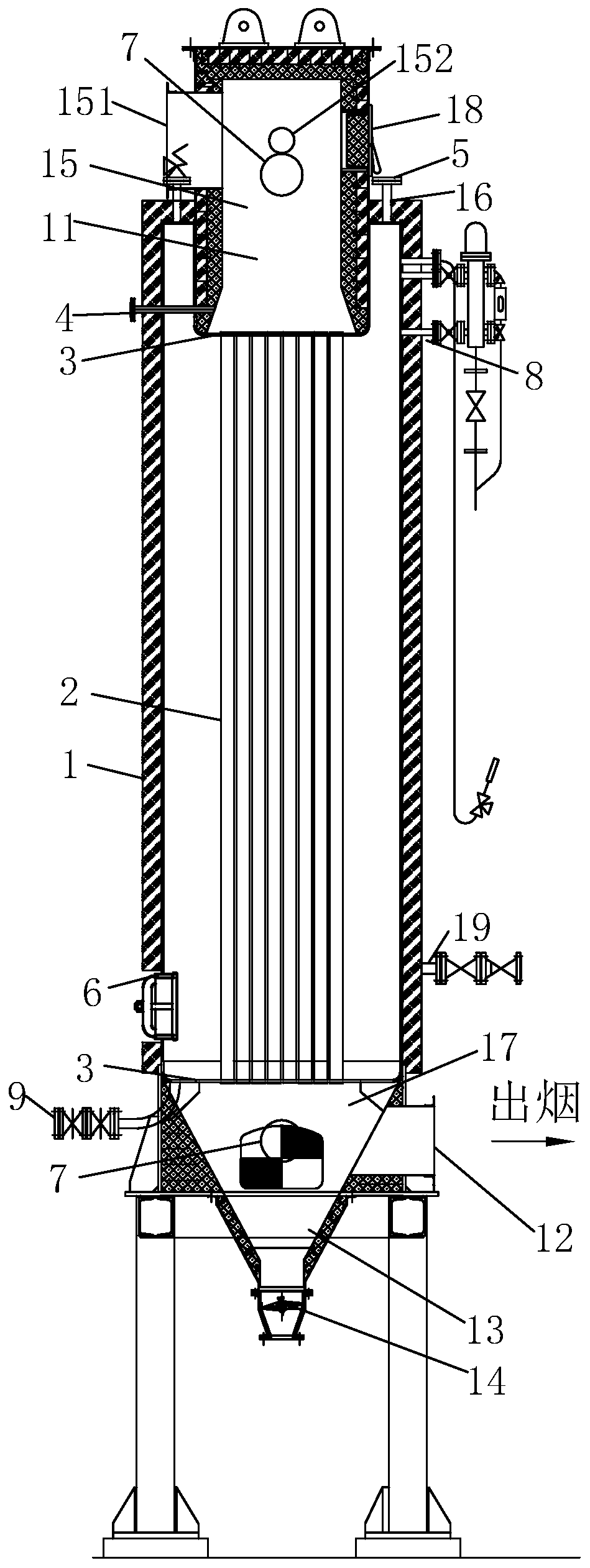

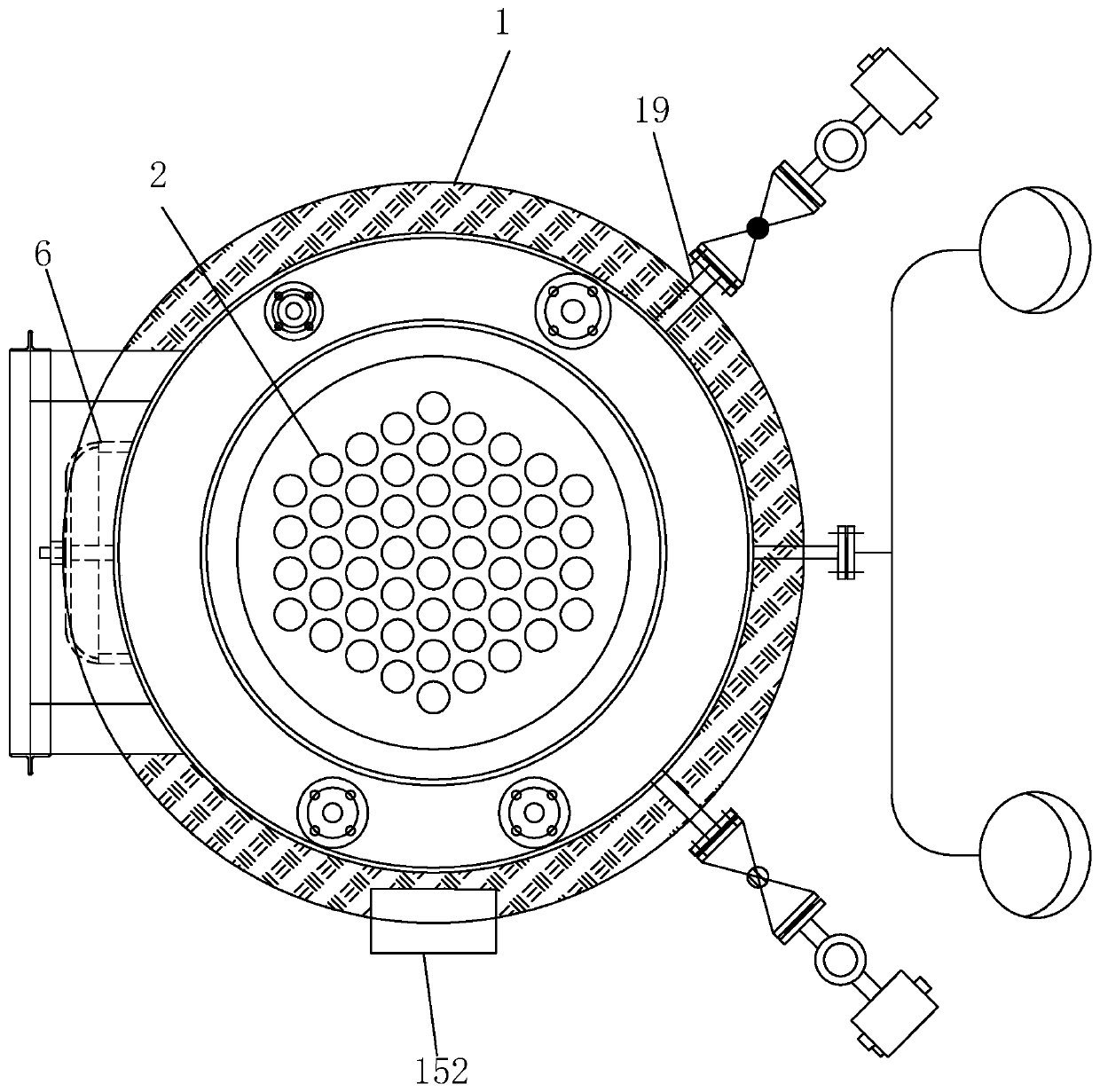

[0045] The following is attached Figure 1-2 And embodiment the present invention is described in further detail.

[0046] A kind of environmental protection and energy-saving quick cooler, such as figure 1 As shown, it includes a housing 1 and several smoke ducts 2 arranged in the housing 1. The housing 1 is provided with a smoke inlet 11 communicating with one end of the smoke duct 2. The housing 1 is far away from the smoke inlet. There is a flue gas outlet 12 at one end of the shell; the circulating coolant is filled in the casing 1; both ends of the smoke pipe 2 are isolated from the cooling liquid; There is a seal 14 movable there.

[0047] The incinerated flue gas enters the flue gas duct 2 from the flue gas inlet 11, exchanges heat with the cooling liquid in the shell 1, and is discharged from the flue gas outlet 12 after cooling below 220°C; because the cooling liquid is circulated Circulating, so the cooling effect is very good. At the same time, the flue gas is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com