Stretchable fabric

A fabric and warp technology, applied in the direction of fabrics, multi-strand fabrics, textiles, etc., can solve the problems of rising manufacturing costs and complex manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

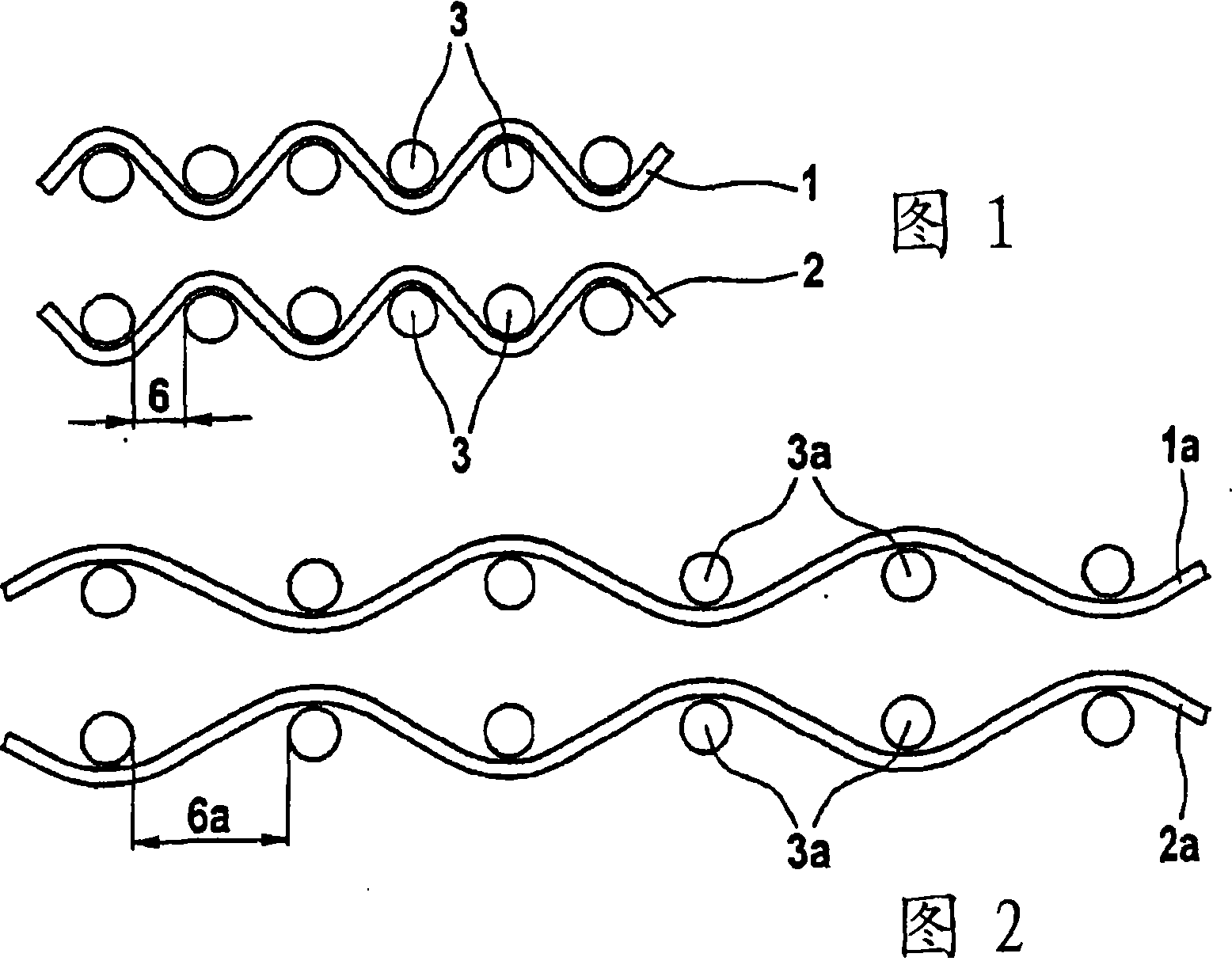

[0018] Referring now to FIG. 1, there is shown in a greatly enlarged circle a weft yarn 3 interwoven by warp yarns 1 and 2 in a fabric woven in a conventional L1 / 1 plain weave, where two weft The spacing between the yarns is indicated with reference numeral 6 . FIG. 1 top view shows a fabric section along a first warp thread 1 surrounding a weft thread 3 .

[0019] The next view shows a plain weave fabric section as known from the prior art along the second warp thread 2 . The spacing 6 between weft threads 3 (between warp threads, the same response) is defined by the structure.

[0020] Reference is now made to Figure 2 which shows a cross-section of the fabric shown in Figure 1 but in a stretched state, that is to say for example as the fabric is applied in an inflated or inflated airbag. Injecting an airbag (not shown) with gas generated by an inflator (not shown) and / or cushioning the impact of the vehicle occupant results in a tensile loading of the fabric so that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com