Manufacturing method of heat-not-burn fuming body

A heat-not-burn and manufacturing method technology, applied in the fields of tobacco, tobacco preparation, smoker’s supplies, etc., can solve the problems of limited promotion and popularization, heavy quality, uneven heating of cigarettes, etc., and achieve sufficient and uniform heating, smoking smoke The effect of fully and enhancing the sense of experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

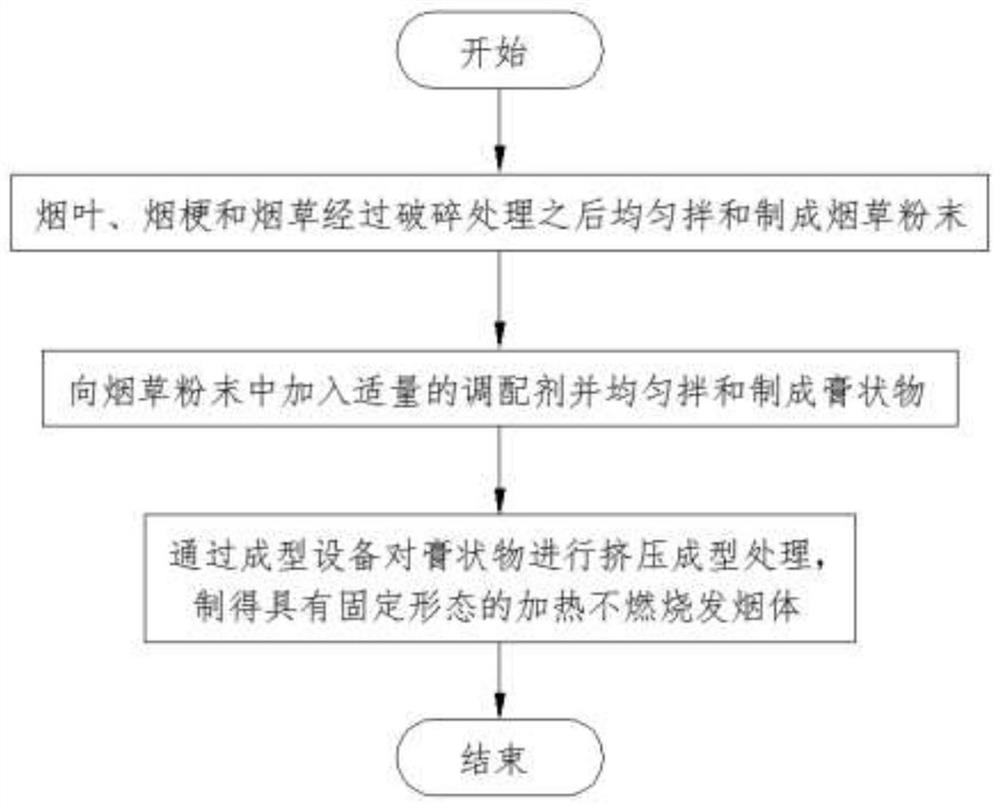

[0023] The invention provides a method for manufacturing a heat-not-burn smoke body, such as figure 1 shown, including the following steps;

[0024] Step 1: After the tobacco leaves, tobacco stems and tobacco are crushed, they are evenly mixed to form tobacco powder; further, the particle size of the tobacco powder in step 1 is 60 mesh to 120 mesh.

[0025] Step 2: Add an appropriate amount of preparation agent to the tobacco powder in step 1 and uniformly stir to form a paste; preferably the preparation agent is one or more mixtures of glycerin, propylene glycol, invert sugar, glutinous rice flour, and flavors and fragrances. The mass ratio of the compounding agent to the tobacco powder is 25:100 to 45:100.

[0026] Step 3: Take the paste in step 2, and extrude it through a molding device to obtain a heat-not-burn fuming body wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com