Pre-forming process of vegetable protein meat and vegetable protein meat product thereof

A vegetable protein meat and preforming technology, which is applied in the preforming process of vegetable protein meat and the field of vegetable protein meat products, and can solve the problems affecting the flavor of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

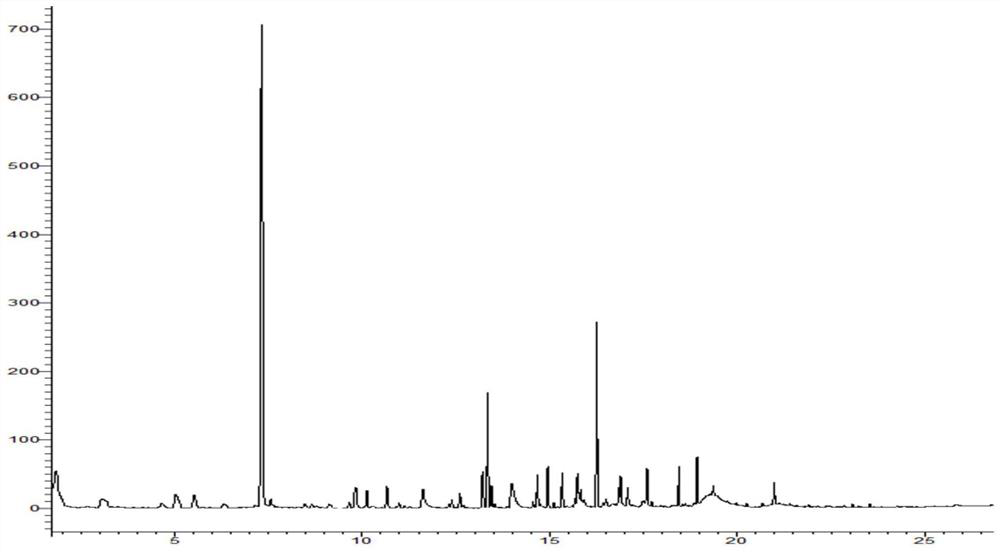

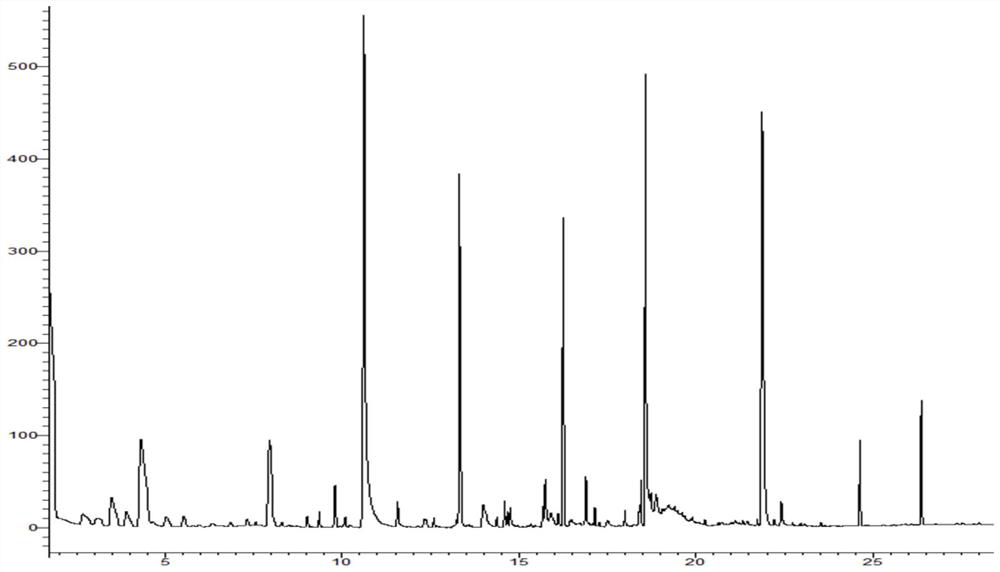

Image

Examples

Embodiment 1

[0029] This embodiment provides a preforming process for vegetable protein meat, and the specific processing steps are as follows:

[0030] (1) Rehydration, soak the soybean silk protein in a 40°C water bath until there is no hard core;

[0031] (2) Washing and dehydration, repeatedly washing the rehydrated soybean silk protein until the washed water is basically colorless, after washing, put it into a dehydrator for dehydration, repeat three times until the protein is basically constant;

[0032] (3) Dismantling and chopping, put the dehydrated soybean silk protein into a dismantling machine (Braun FP3010) to dismantle the dissected silk, and use the chopping machine to cut the dismantled silk into pieces with a length of 0.5cm and a width of 0.1~0.5cm ;

[0033] (4) Dissolve the mixture of agar and sodium alginate (the mass ratio of agar and sodium alginate is 1:1) into distilled water to obtain an aqueous solution of agar sodium alginate, mix citric acid and palm oil to ob...

Embodiment 2

[0035] Embodiment 2 (comparative example 1, without washing)

[0036] This embodiment provides a preforming process for vegetable protein meat, and the specific processing steps are as follows:

[0037] This embodiment provides a preforming process for vegetable protein meat, and the specific processing steps are as follows:

[0038] (1) Rehydration, soak the soybean silk protein in a 40°C water bath until there is no hard core;

[0039] (2) Dehydration, the soybean silk protein after rehydration is directly dehydrated until the protein is basically constant weight;

[0040] (3) Dismantling and chopping, put the dehydrated soybean silk protein into a dismantling machine (Braun FP3010) to dismantle the dissected silk, and use the chopping machine to cut the dismantled silk into pieces with a length of 0.5cm and a width of 0.1~0.5cm ;

[0041] (4) Dissolve the mixture of agar and sodium alginate (the mass ratio of agar and sodium alginate is 1:1) into distilled water to obtai...

Embodiment 3

[0043] Embodiment 3 (comparative example 2, without sustained-release solution)

[0044] This embodiment provides a preforming process for vegetable protein meat, and the specific processing steps are as follows:

[0045] (1) Rehydration, soak the soybean silk protein in a 40°C water bath until there is no hard core;

[0046] (2) Washing and dehydration, repeatedly washing the rehydrated soybean silk protein until the washed water is basically colorless, after washing, put it into a dehydrator for dehydration, repeat three times until the protein is basically constant;

[0047] (3) Dismantling and chopping, put the dehydrated soybean silk protein into a dismantling machine (Braun FP3010) to dismantle the dissected silk, and use the chopping machine to cut the dismantled silk into pieces with a length of 0.5cm and a width of 0.1~0.5cm ;

[0048] (4) Put the soybean silk-drawn protein prepared in (3) into a cooking machine, stir and mix evenly at a low speed, add konjac gum an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com