Cake cream flattening device for food processing

A technology for food processing and cakes, which is applied in the field of cake cream smoothing devices for food processing, and can solve the problems that manual processing cannot meet the efficiency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

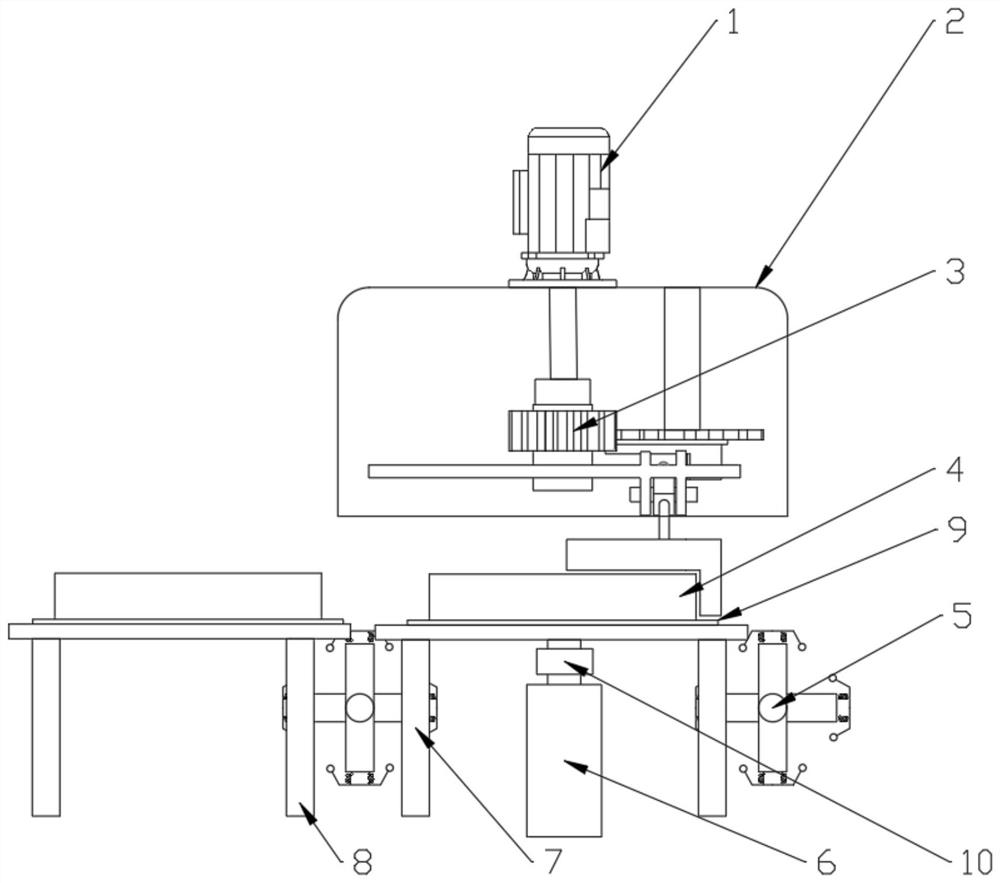

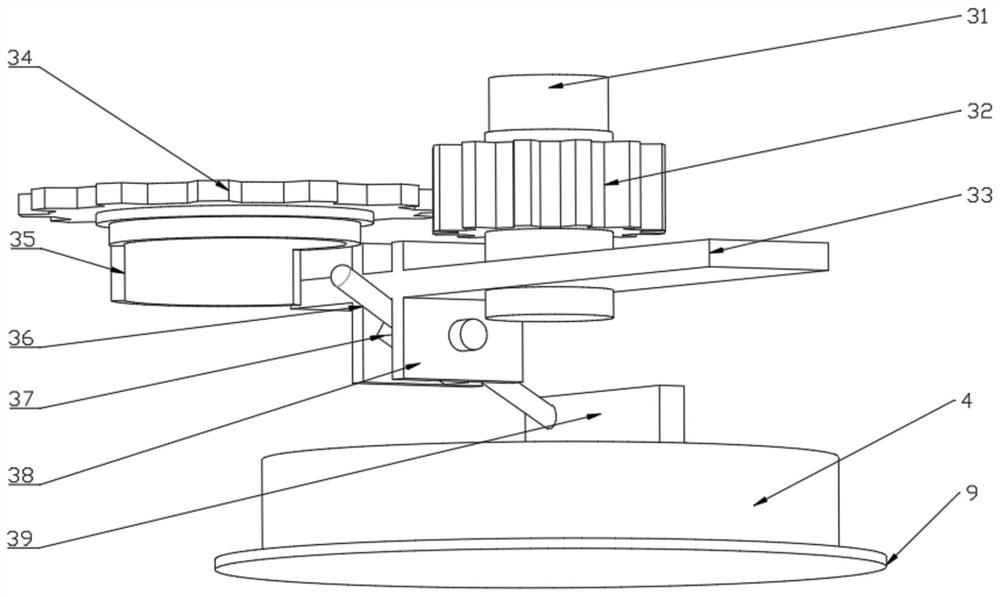

[0023] see Figure 1-5 , a cake cream smoothing device for food processing, comprising a smoothing platen 39 and a backing plate 9, the leveling platen 39 is located above the backing plate 9, and also includes a housing 2, and the housing 2 is provided with There is a smoothing mechanism 3, and the first motor 1 is arranged on the outside; the smoothing mechanism 3 includes the smoothing pressing plate 39 and a drive module, and the smoothing pressing plate 39 performs a smoothing motion on the cake 4 through the driving module, so The cake 4 is arranged on the upper end of the backing plate 9; the driving module includes a first gear 32, a second gear 34, a smoothing pressing plate 39 and an adjustment pressure block 35, and the first gear 32 is sleeved on the outside of the rotating shaft 31, so One end of the rotating shaft 31 is connected to the output end of the first motor 1, and the other end is connected to a connecting plate 33, and the first gear 32 is driven to rot...

Embodiment 2

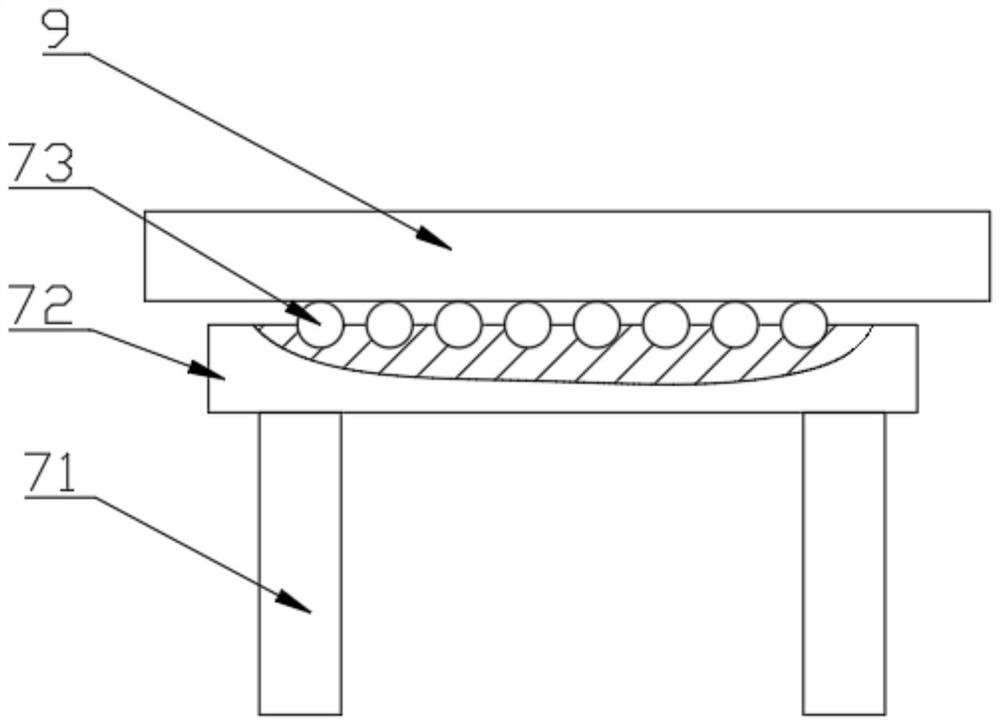

[0029] In order to further improve the applicability of this design, special improvements have been added on the basis of Embodiment 1. The improvements are: please refer to Figure 1-5 A transition frame 8 is also provided on one side of the support frame 7, and the structure of the transition frame 8 is the same as that of the support frame 7. Through the support frame 7 and the transition frame 8 having the same structure, the cake 4 on the transition frame 8 can be directly entered into the support frame 7 under the driving action of the thrust, thus ensuring the stability of feeding.

[0030]A feeding mechanism 5 is also arranged between the support frame 7 and the transition frame 8, and the feeding mechanism 5 includes a feeding rotating shaft 51 and a rotating rod 52, and several rotating rods 52 are installed on the circumferential surface of the feeding rotating shaft 51. A power mechanism that drives the rotation of the feeding rotating shaft 51 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com