Multistage horn-shaped backflushing discharge arc extinguishing tube

A technology of arc extinguishing tube and trumpet type, which is applied in the direction of circuits, electrical components, spark gaps, etc., and can solve problems such as line safety accidents, loss of application functions, failure of insulation coordination in parallel protection gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

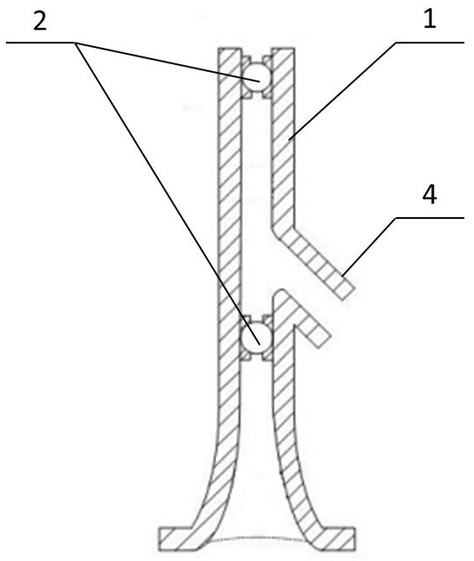

[0038] Such as figure 1 As shown, a multi-stage trumpet-type recoil discharge arc extinguishing tube includes an arc extinguishing tube body 1, a lightning connection electrode 2 and a side recoil tube 4; the side recoil tube 4 is arranged in the arc extinguishing tube On the side wall of the main body 1, and the side recoil tube 4 communicates with the arc extinguishing tube body 1; the lightning connection electrode 2 is embedded in the arc extinguishing tube body 1, and the side recoil tube 4 is above and below both A lightning connection pole 2 is provided to make the arc extinguishing tube body 1 form a semi-closed space; the diameter of the arc extinguishing tube body 1 gradually increases from top to bottom, so that the arc extinguishing tube body 1 is trumpet-shaped. There are two lightning-connecting poles 2, which are equidistantly embedded in the arc extinguisher body 1; the lightning-connecting poles 2 are circular. The side stage recoil pipe 4 is a straight cylin...

Embodiment 2

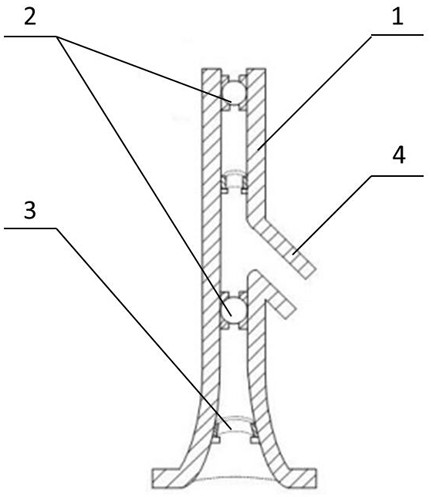

[0040] The difference between this embodiment and embodiment 1 is: as figure 2 As shown, the arc extinguishing tube body 1 is further provided with two hollow metal horn rings 3 ; the metal horn rings 3 are equidistantly arranged in the arc extinguishing tube body 1 .

[0041] The purpose of adding the metal horn ring 3 in this implementation is to ensure that the electric arc can enter the arc extinguisher body 1 smoothly by using the metal conductivity to realize the recoil function, and the metal horn ring 3 can also play a role in protecting the arc extinguisher body.

Embodiment 3

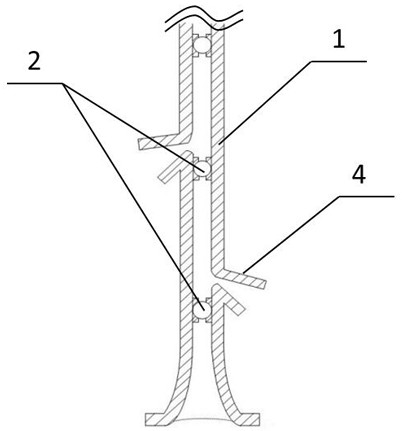

[0043] The difference between this embodiment and embodiment 1: as image 3 As shown, the side-stage recoil pipe 4 is trumpet-shaped, and there are more than two.

[0044] In this embodiment, the side-stage recoil pipe 4 is a trumpet type, and the purpose is to increase the density difference, temperature difference, and pressure difference between the inside and outside of the pipe, so that the recoil injection effect of the airflow is stronger, and the trumpet-shaped side-stage recoil pipe 4 The arc extinguishing effect is more obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com