Water level control method and device, liquid storage equipment, steam oven and readable storage medium

A water level control and liquid storage technology, applied in liquid level control, non-electric variable control, control/regulation system, etc., can solve the problem of difficult removal of accumulated water in the evaporator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

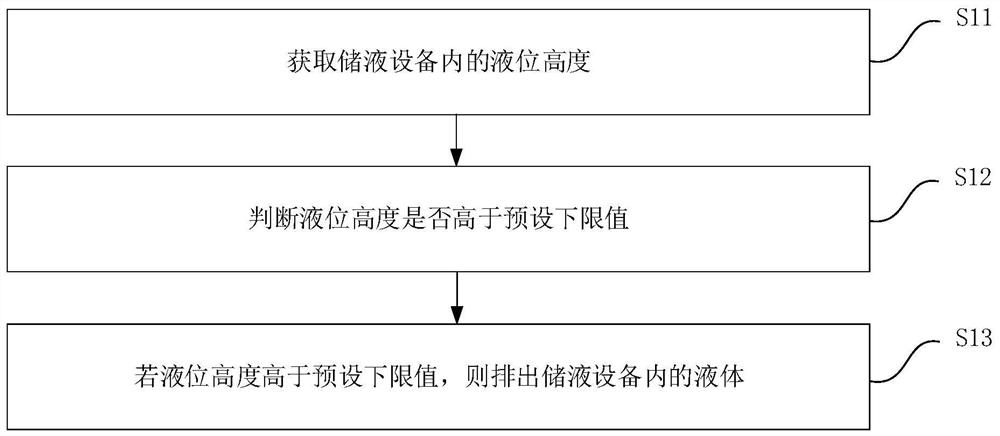

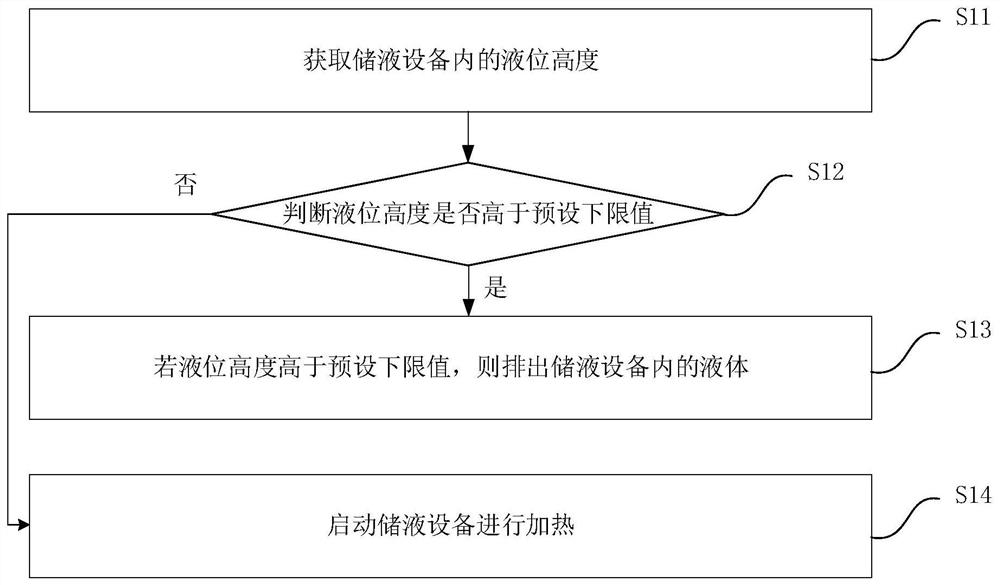

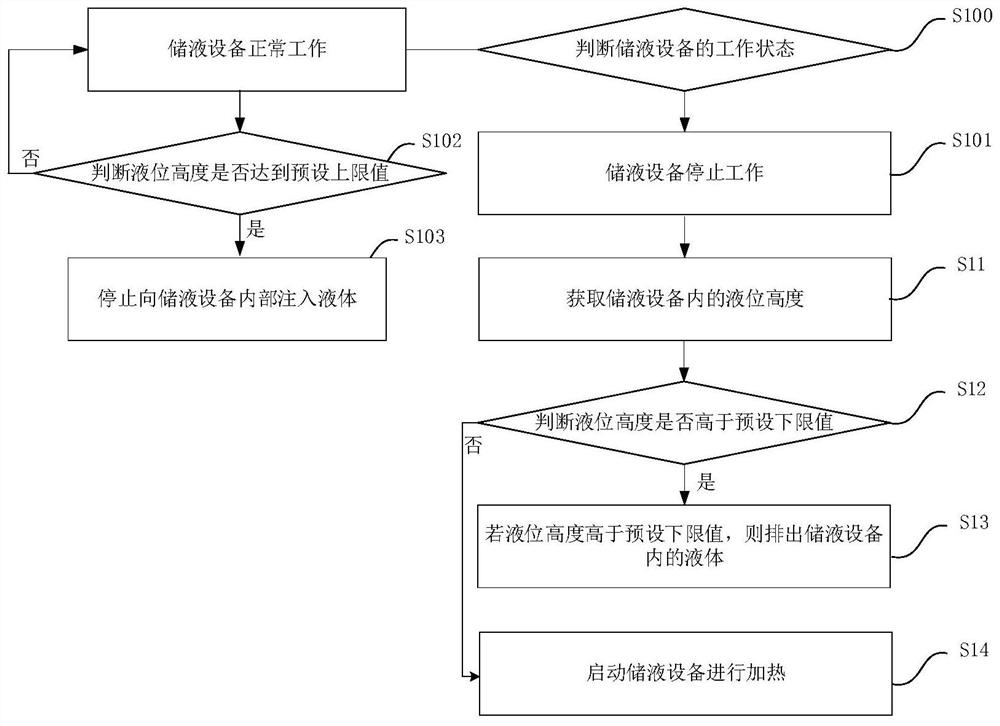

[0033] This embodiment provides a water level control method, which can be applied to a liquid storage device of a cooking appliance used by a user. The liquid storage device can be an evaporator, a water tank, etc. The present invention takes a steam oven including an evaporator as an example. Such as figure 1 As shown, the water level control method includes the following steps:

[0034] S11. Obtain the liquid level in the liquid storage device.

[0035] Exemplarily, the liquid level height refers to the liquid height in the liquid storage device. Specifically, an evaporator is used as an example of the liquid storage device, and the liquid level can be obtained through a liquid level detection component arranged inside the evaporator. The liquid level detection component may be a liquid level sensor. Specifically, the liquid level sensor may be arranged at the bottom of the evaporator and extend upwards to detect the liquid level in the evaporator in real time. The prese...

Embodiment 2

[0061] This embodiment provides a water level control device, which can be applied to a liquid storage device of a cooking appliance used by a user. The liquid storage device can be an evaporator, a water tank, etc. The present invention takes a steam oven including an evaporator as an example. Such as Figure 5 As shown, the water level control device includes:

[0062] The acquiring module 21 is configured to acquire the liquid level in the liquid storage device. For details, refer to the relevant description of step S11 corresponding to the above method embodiment, and details are not repeated here.

[0063] The first judging module 22 is configured to judge whether the liquid level is higher than a preset lower limit. For details, refer to the relevant description of step S12 corresponding to the above method embodiment, which will not be repeated here.

[0064] The liquid discharge module 23 is configured to discharge the liquid in the liquid storage device if the liqu...

Embodiment 3

[0079] This embodiment provides a liquid storage device, which can be applied to a steam oven used by a user or other cooking appliances including a liquid storage device. The present invention takes a steam oven as an example. Such as Figure 6 As shown, the liquid storage device includes: a liquid level detection component 31 , a controller 32 and a drain pump 33 .

[0080] Wherein, the liquid level detection component 31 is arranged inside the liquid storage device, and is used for detecting and outputting liquid level height information. For details, refer to relevant descriptions corresponding to the foregoing embodiments, and details are not repeated here.

[0081] The controller 32 includes: an acquisition module 21, which is used to acquire the liquid level in the liquid storage device; a first judging module 22, which is used to judge whether the liquid level is higher than a preset lower limit; a liquid discharge module 23, if the liquid level If the height is high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com