Device for reinforcing UHPC-NC interface bonding by adopting perforated steel plates and using method

A technology of UHPC-NC and perforated steel plates, which can be applied to building reinforcements, structural elements, truss structures, etc., and can solve problems such as insufficient bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a deeper understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

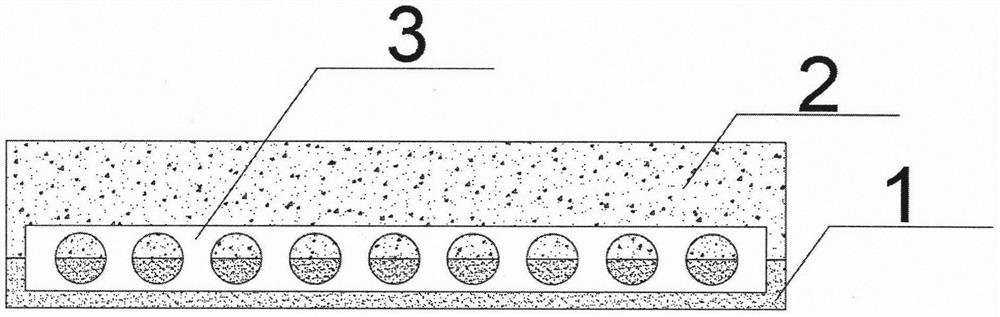

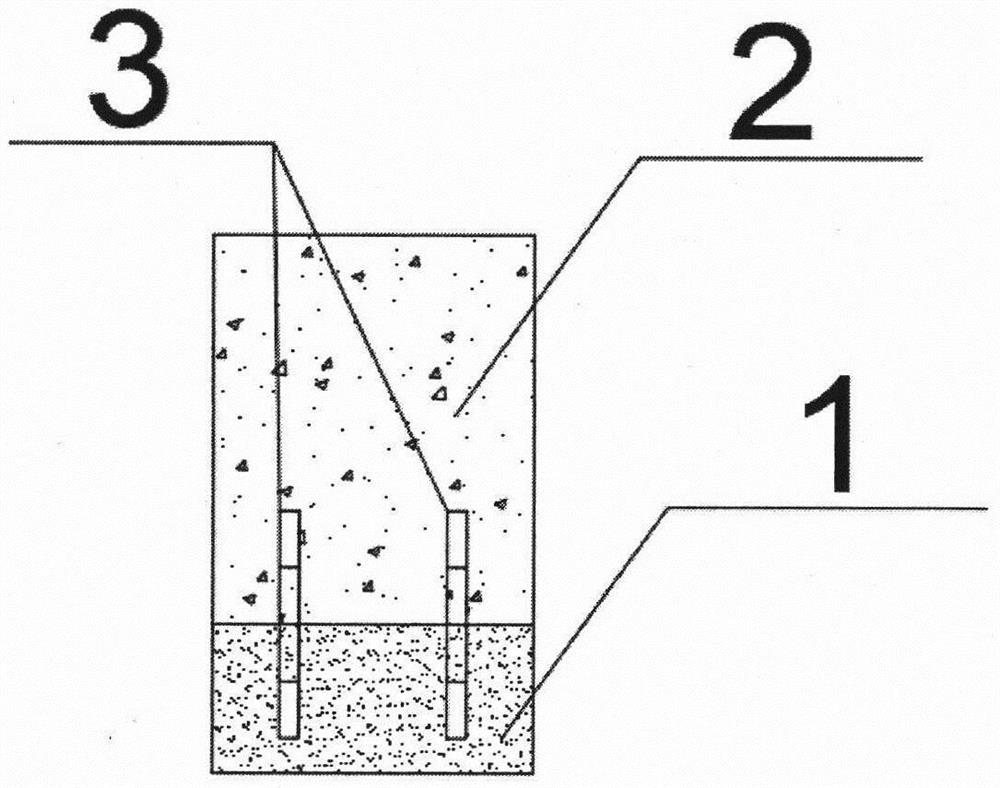

[0022] A device for strengthening UHPC-NC interface bonding by using perforated steel plates, making perforated steel plates 3 as connectors between UHPC1 and NC1 interfaces, the height of each steel plate is set at 8cm to 12cm, and the axis in the length direction of each steel plate Open the upper hole, the aperture should be half the height of the steel plate, the edge of the aperture should not be less than 2cm from the edge of the steel plate, the length of the steel plate should be 10cm to 20cm shorter than the length of the beam, and the thickness of the concrete protective layer between the longitudinal edge of the steel plate and the edge of the beam should not be less than 5cm;

[0023] In the device for strengthening UHP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com