Immersed tube tunnel tube segment gravity anchor

An immersed tunnel, gravity anchor technology, applied in water conservancy projects, artificial islands, sheet pile walls, etc., can solve the problems of small anchor blocks, little benefit of anchor block lifting, and easy insertion into seabed soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

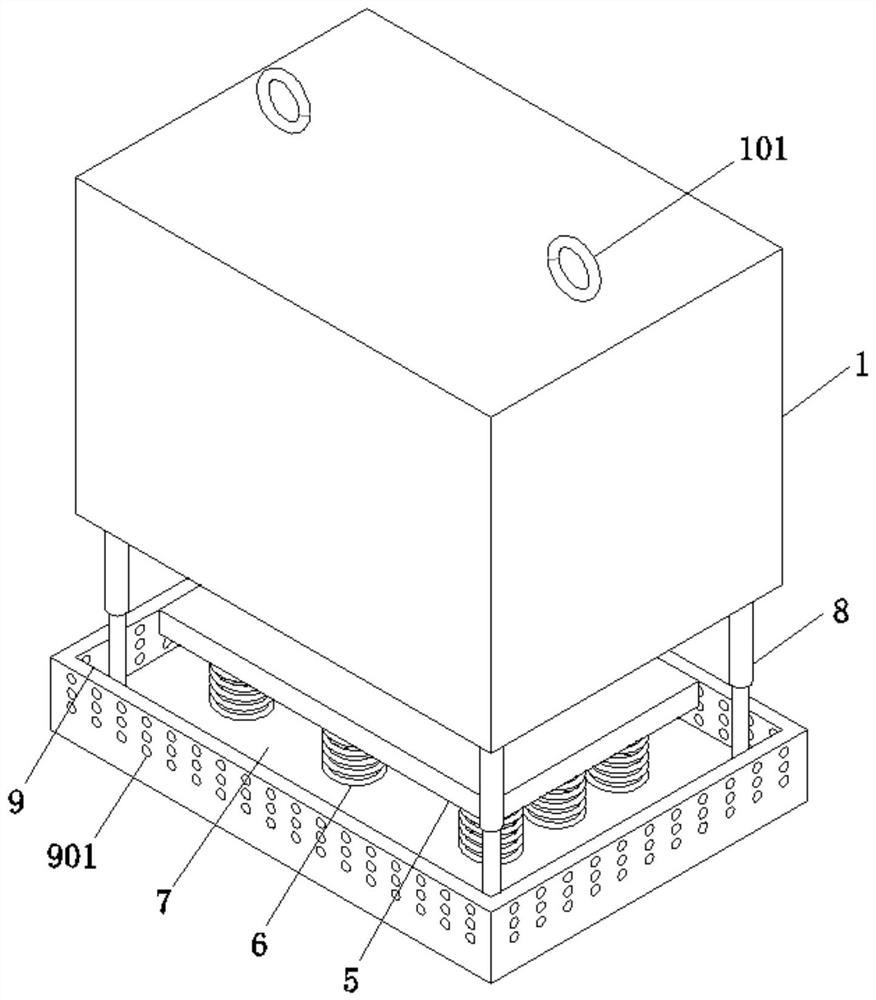

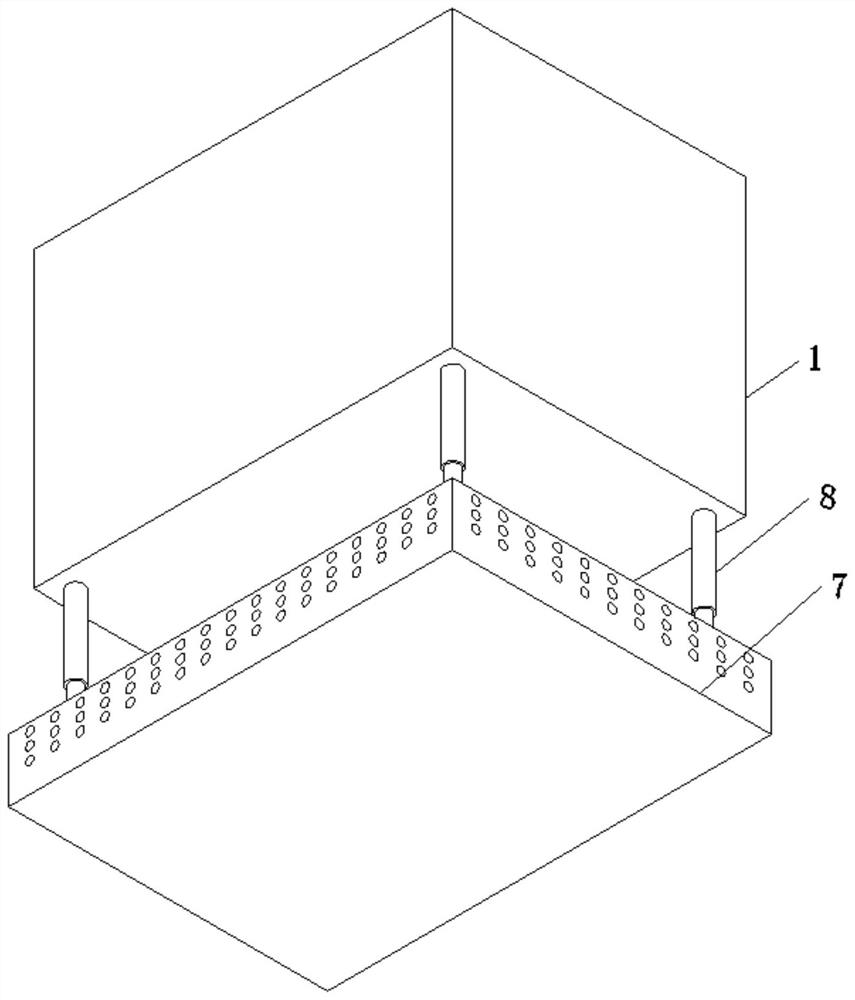

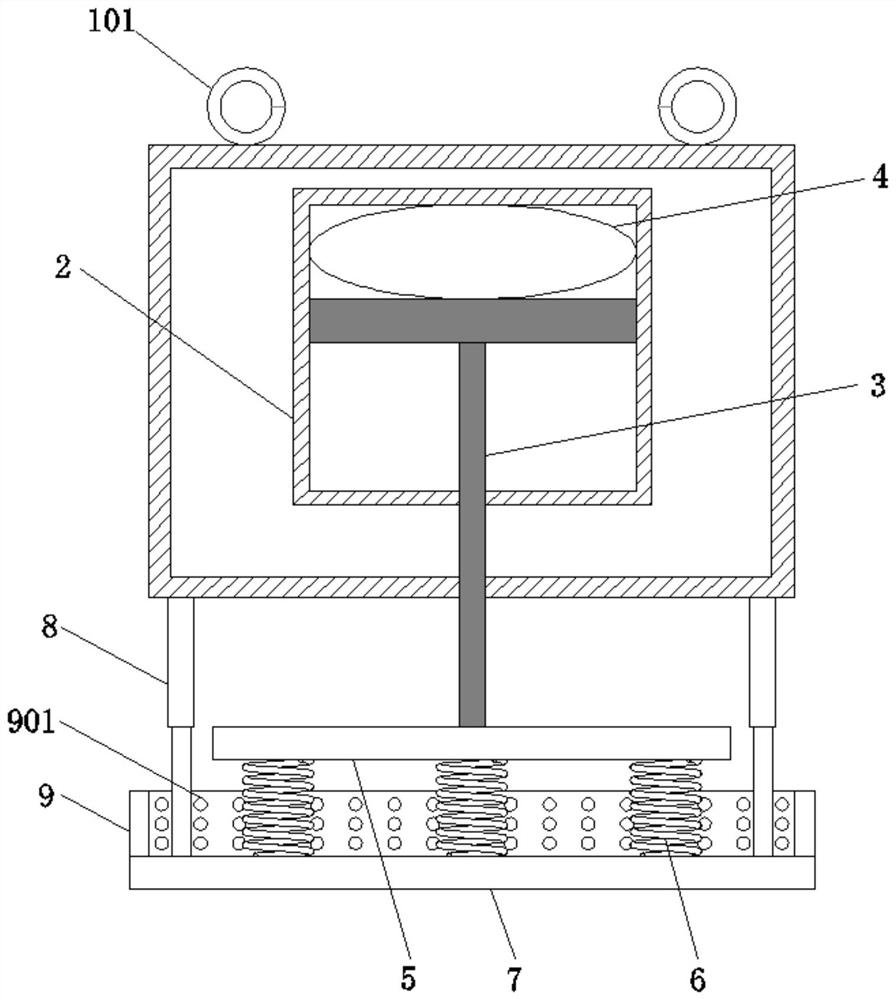

[0022] refer to Figure 1-4 , a gravity anchor for immersed tube tunnel sections, including an anchor block 1, two groups of symmetrically arranged lifting rings 101 are connected to the top of the anchor block 1, the interior of the anchor block 1 is a hollow structure, and the interior of the anchor block 1 is connected with a movable box 2, The inner side wall of the movable box 2 is slidingly connected with a piston 3, and the movable box 2 is internally connected with an air bag 4, the air bag 4 is located above the piston 3, the air inlet of the air bag 4 is connected with the air compressor, and the bottom of the anchor block 1 Connected with a support plate 7, the bottom of the piston 3 extends outward through the movable box 2 and the bottom of the anchor block 1, and the extension end of the piston 3 placed outside the anchor block 1 is connected with a pressure plate 5, and the pressure plate 5 cooperates with the support plate 7 , an elastic reset member is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com