Underwater concrete pouring device in steel pipe and concrete pouring method

A technology of underwater concrete and concrete, which is used in construction, infrastructure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

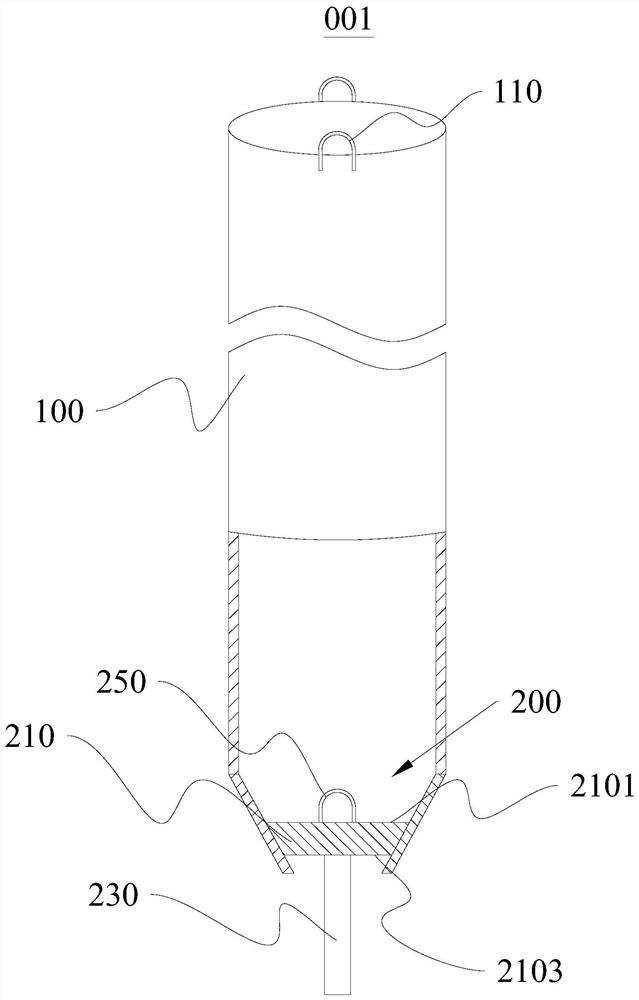

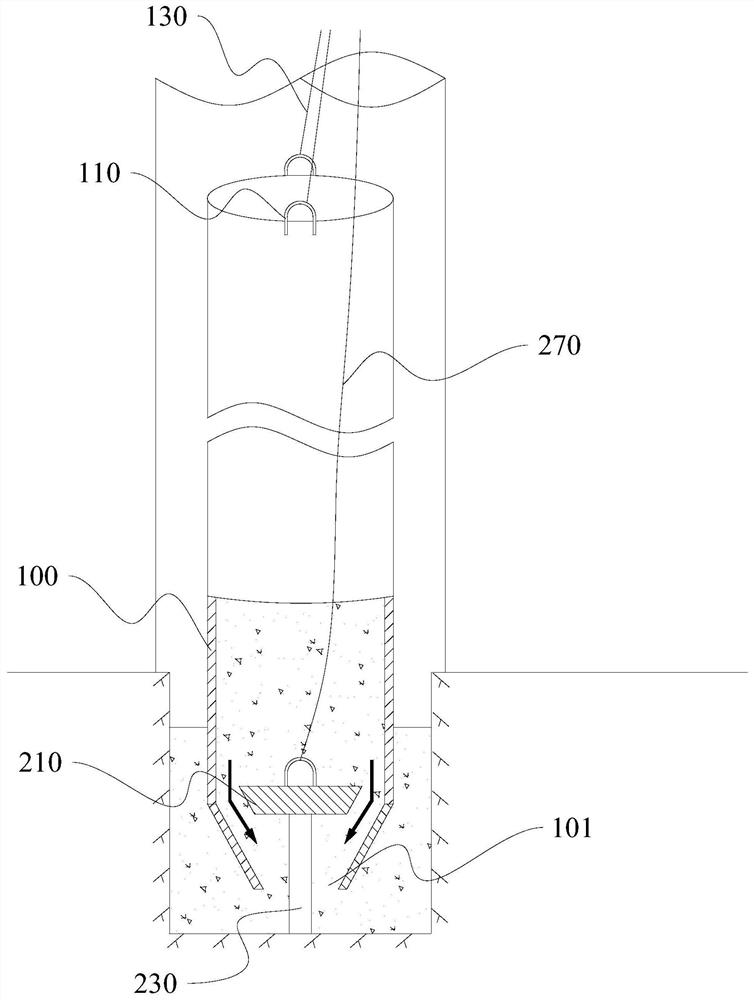

[0030] This embodiment provides an underwater concrete pouring device 001 in steel pipes, which is used for underwater concrete pouring in steel pipes for locking steel pipe pile cofferdams in deep water. Please refer to figure 1 and figure 2 , this underwater concrete pouring device 001 in a steel pipe includes a container pipe 100 and a plugging member 200;

[0031] The outer diameter of the container pipe 100 is slightly smaller than the inner diameter of the steel pipe of the deep-water locking steel pipe pile cofferdam, so that the container pipe 100 can extend into the steel pipe of the deep-water locking steel pipe pile cofferdam.

[0032] The container pipe 100 is used to accommodate the concrete that needs to be poured into the cofferdam of deep-water locking steel pipe piles. The bottom end of the container pipe 100 forms a constricted concrete outlet 101. When in use, the concrete in the container pipe 100 is discharged through the concrete outlet 101 .

[0033] ...

Embodiment 2

[0042] This embodiment provides a concrete pouring method, using the underwater concrete pouring device 001 in a steel pipe provided in Embodiment 1 to pour concrete, including steps:

[0043] Place the plug 200 into the bottom of the container pipe 100, and the steel rod 230 protrudes out of the concrete outlet 101;

[0044] The container pipe 100 is lowered into the steel pipe of the deep water locked steel pipe pile cofferdam through the second suspension rope 130;

[0045] The plugging member 200 descends following the container pipe 100 until it abuts against the bottom of the steel pipe of the deepwater locking steel pipe pile cofferdam;

[0046]The stopper 200 stops falling due to the abutment of the steel rod 230, and at the same time continues to lower the container tube 100, so that the seal of the tapered plate 210 fails;

[0047] The concrete outlet 101 of the container pipe 100 is opened, and the concrete in the container pipe 100 communicates with the concrete i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com