Intelligent grouting equipment and pile foundation construction method

An intelligent and equipment-based technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as difficulty in moving the grouting machine, dispersion, and inability to guarantee the quality of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

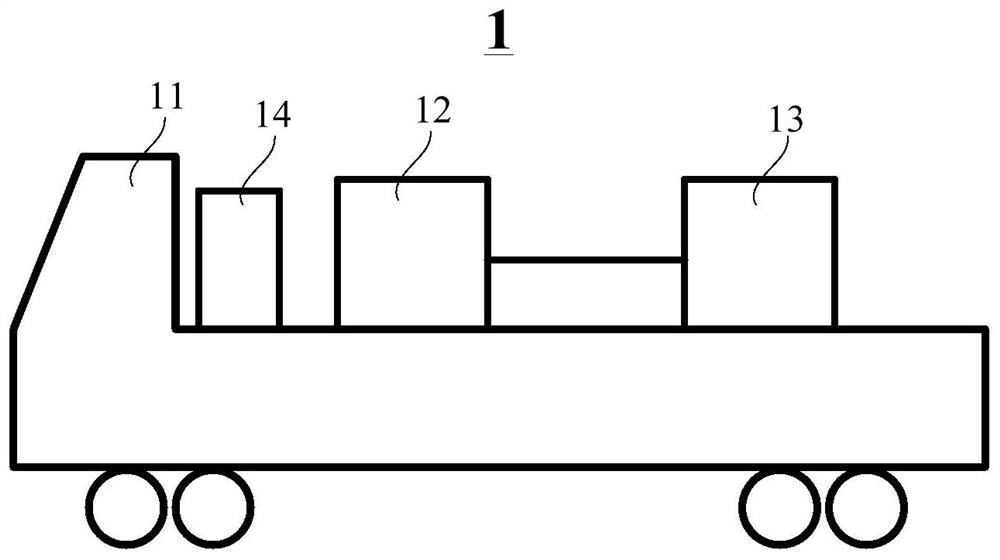

[0043] like figure 1 , figure 2 and image 3 As shown in the structure, the embodiment of the present application provides an intelligent grouting equipment 1, the intelligent grouting equipment 1 includes a mobile trolley 11, a pulping machine 12, a pulping machine 13 and a control device 14;

[0044] Mobile trolley 11 comprises car body; As figure 1 As shown in the structure, the mobile trolley 11 includes a car body, and the bottom of the car body is provided with wheels. The mobile trolley 11 can also include a power system such as a driving device (not shown) installed on the car body, and a power system such as a driving device Used to generate driving force and drive the car body to move; the mobile trolley 11 can be driven by its own power system to change its position, or can be driven by an external power source such as a tractor to move the car body;

[0045] Pulp making machine 12 is removably installed on mobile trolley 11, is used for preparing cement slurry;...

Embodiment 2

[0059] The embodiment of the present application also provides a pile foundation construction method using any one of the intelligent grouting equipment 1 in the above embodiments for grouting, such as Figure 4 shown, including the following steps:

[0060] Step S10, drill hole 2; drill hole 2 by a drilling rig at the position where the pile foundation needs to be set;

[0061] Step S20, arranging the reinforcement cage 3 and the grouting pipe 4 into the drilled hole 2; the reinforcement cage 3 can be a prefabricated part, or made on site;

[0062] Step S30, clearing the hole 2;

[0063] Step S40, setting the water-cement ratio of the pulper 12;

[0064] Step S50, connecting the pulp outlet of the pulp press 13 of the intelligent pulping equipment 1 with the inlet of the pulping pipe 4;

[0065] Step S60, using the pulping machine 12 of the intelligent grouting equipment 1 for pulping to form cement slurry;

[0066] In step S70, the cement slurry prepared by the pulping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com