Method for continuously preparing pimavanserin by using micro-channel reactor

A technology of microchannel reactor and pimavanserin, which is applied in the field of medicine and chemical industry, can solve the problems of high price of DPPA, high production risk and difficulty in industrialization, so as to improve the overall safety, occupy less production space and lower the price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

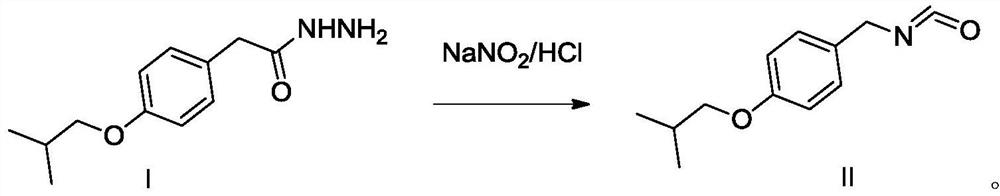

[0037] Embodiment 1: the synthesis of hydrazide compound (I)

[0038] Add 100g of p-hydroxyphenylacetic acid into a 500mL four-necked bottle, add 300ml of ethanol, add 83g of thionyl chloride dropwise at 0-10°C, heat up to 65-70°C to react for 2-3 hours, concentrate to remove ethanol, and obtain p-hydroxyl Ethyl phenylacetate. Yield 98%.

[0039] Add 200mL DMF, 115g potassium carbonate, 50g ethyl p-hydroxyphenylacetate and 76g bromoisobutane into a 500mL four-neck flask, stir and heat to 75-80°C for 2 hours, cool and filter to remove solids, add water and ethyl acetate ester, the organic phase was separated and concentrated to obtain the product ethyl 4-isobutoxybenzoate with a yield of 90%.

[0040] Add 100g of ethyl 4-isobutoxybenzoate, 500mL of ethanol, 100mL of 80% hydrazine hydrate into a 1000mL reaction flask, heat and reflux to keep the reaction until the ethyl 4-isobutoxybenzoate is less than 0.5%, and recover ethanol by distillation About 300mL, stop the distillati...

Embodiment 2

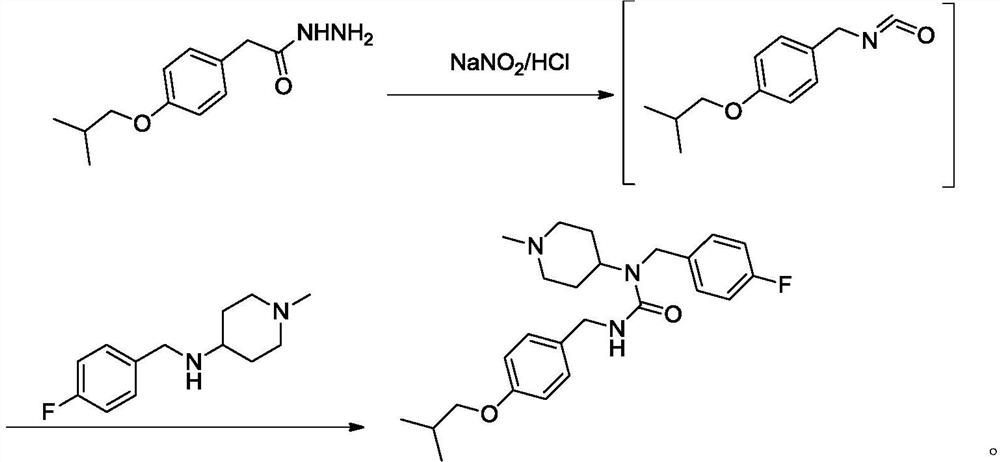

[0041] Embodiment 2: microchannel reaction synthesis pimavanserin

[0042]

[0043] Material A: hydrazide compound (I) is dissolved in dichloromethane

[0044] Material B: Sodium Nitrite / Water

[0045] Material C: 30% hydrochloric acid

[0046] Material D sodium hydroxide / water

[0047] Material E: (4-fluorobenzyl)-(1-methylpiperidin-4-yl)amine in dichloromethane

[0048] Silicon carbide reactor holding liquid 20.8mL

[0049] Advection pump 4 sets

[0050] The reactor equipment holds 20 mL of liquid, and there are 10 reaction sheets in total. The first sheet is connected to material A, material B and material C, the fifth sheet is connected to material D, and the sixth sheet is connected to material E. The flow rate of each pump is set according to the molar ratio A: B:C:D:E=1:1.05:1.1:0.95:0.95

[0051] The back pressure valve is connected to the back of the tenth piece, and the set pressure is 1.5MPa

[0052] The temperature of 1-4 reaction sheets is 15-20°C, the tem...

Embodiment 3

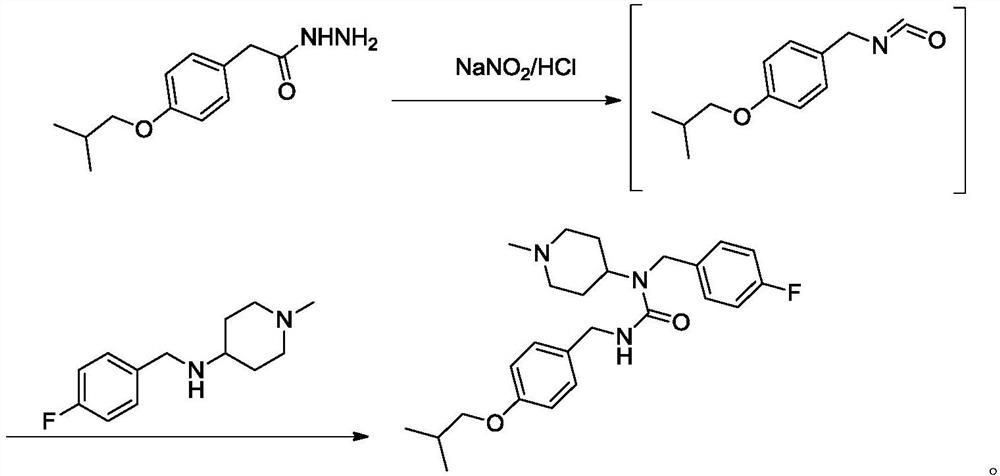

[0054] Embodiment 3: microchannel reaction synthesis pimavanserin

[0055] Material A: hydrazide compound (I) is dissolved in dichloromethane

[0056] Material B: Sodium Nitrite / Water

[0057] Material C: 30% hydrochloric acid

[0058] Material D sodium hydroxide / water

[0059] Material E: (4-fluorobenzyl)-(1-methylpiperidin-4-yl)amine in dichloromethane

[0060] Silicon carbide reactor holding liquid 20.8mL

[0061] Advection pump 4 sets

[0062] The reactor equipment holds 20 mL of liquid, and there are 10 reaction sheets in total. The first sheet is connected to material A, material B and material C, the fifth sheet is connected to material D, and the sixth sheet is connected to material E. The flow rates of each pump are set according to the molar ratio A: B:C:D:E=1:1.2:1.25:0.95:0.95

[0063] The back pressure valve is connected to the back of the tenth piece, and the set pressure is 1.5MPa

[0064] The temperature of 1-4 reaction sheets is 15-20°C, the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com