Electric arc additive forming prediction modeling method based on molten drop transition

A droplet transfer and modeling method technology, applied in additive processing, arc welding equipment, electrode support devices, etc., can solve problems such as limiting simulation prediction accuracy and increasing simulation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] Below in conjunction with accompanying drawing, the present invention is described in further detail:

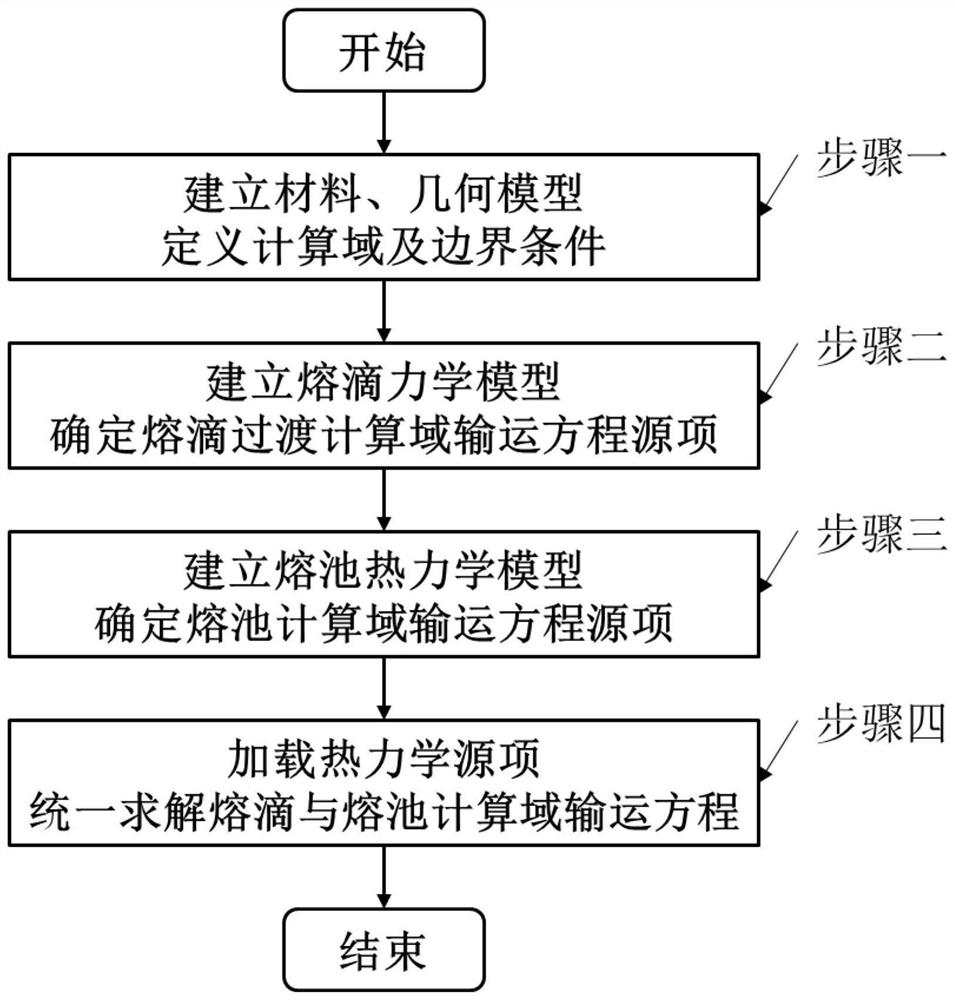

[0111] The present invention proposes a numerical calculation modeling method for arc additive manufacturing based on droplet transfer, which couples the calculation of molten pool flow field with the droplet transfer process, and updates the grid of the calculation domain by considering the movement of the welding torch. Boundary, in the droplet transition calculation domain and molten pool calculation domain, the heat and mass transfer equations are uniformly solved to realize the accurate calculation of the cladding layer morphology, temperature field and flow field in arc additive manufacturing. The main process is as follows: figure 1 shown.

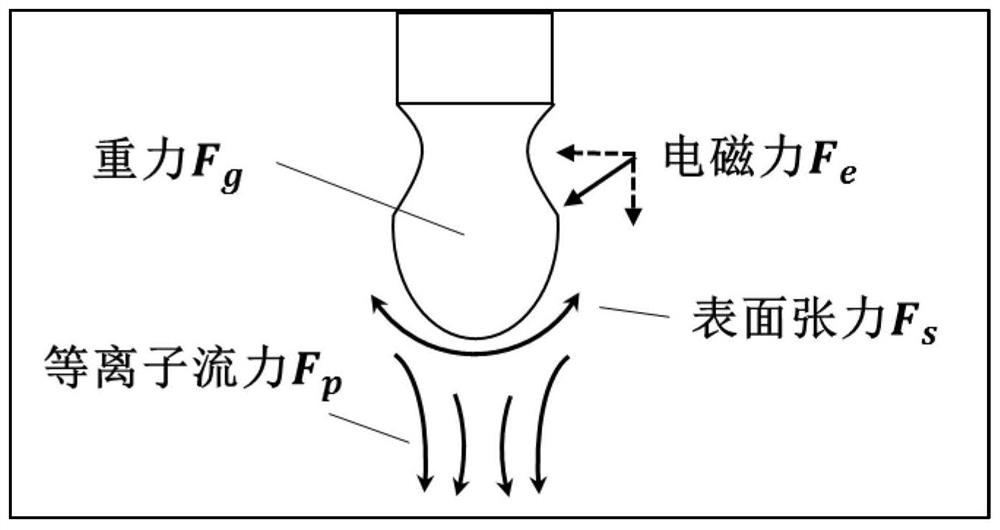

[0112] The numerical calculation and modeling method of arc additive manufacturing based on droplet transfer in the present invention is realized through the following steps:

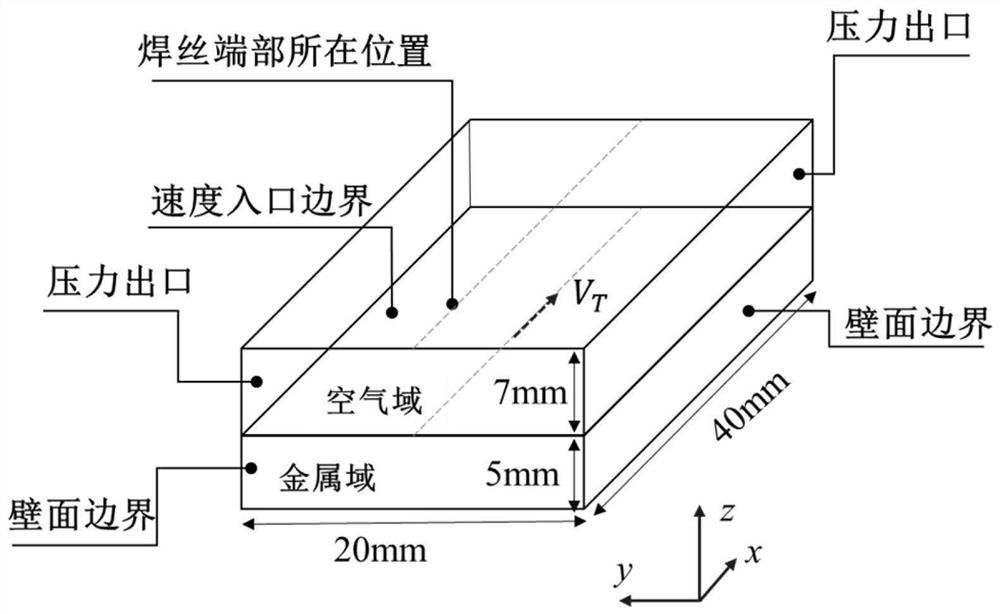

[0113] Step 1: Establish material and geometric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com