Circulating spray absorption tower for flue gas purification treatment

A technology of spray absorption tower and treatment cycle, which is applied in the direction of gas treatment, chemical instruments and methods, cleaning hollow objects, etc., and can solve the problems of poor waste gas treatment effect, inconvenient cleaning, increased equipment investment cost and operating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

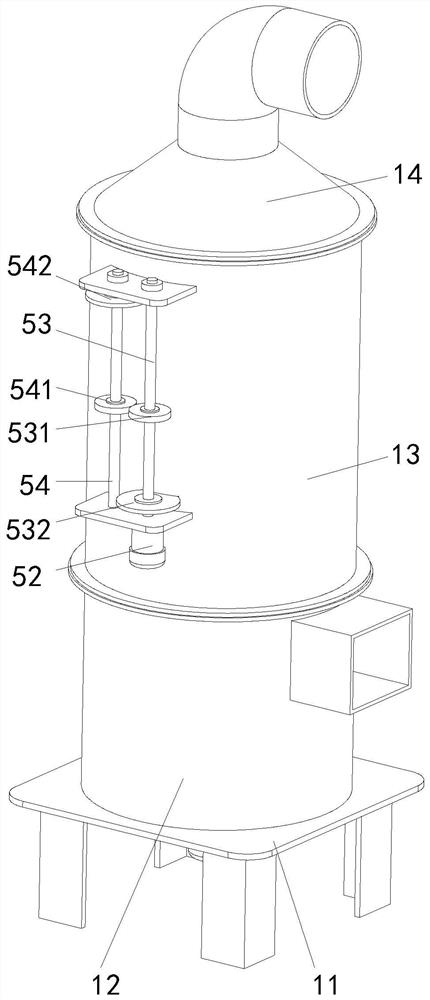

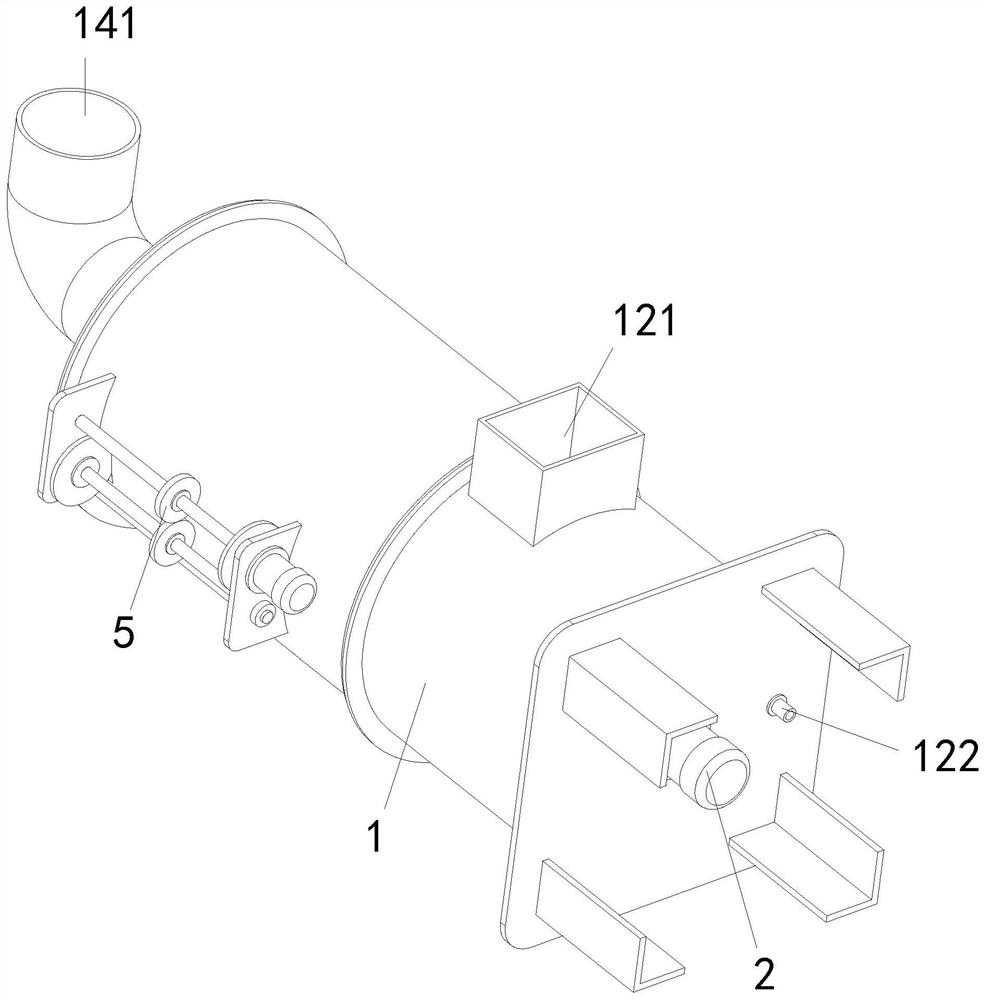

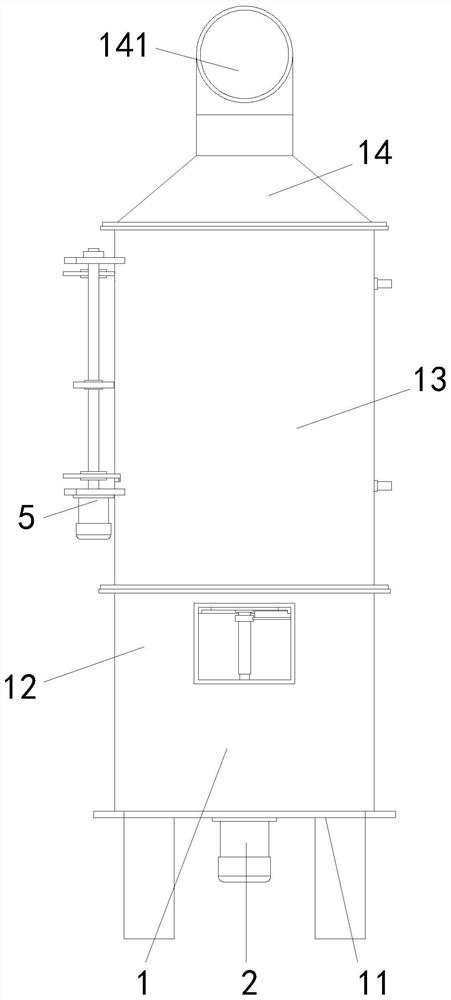

[0031] See attached Figure 1-11 As shown, a flue gas purification treatment circulating spray absorption tower includes an absorption tower body 1, and the absorption tower body 1 includes a cylindrical liquid storage tower body 12 for storing the spray medium liquid and is connected to the top of the liquid storage tower body 12. A cylindrical spray tower body 13, a flue gas inlet 121 for introducing flue gas is provided on the side wall of the liquid storage tower body 12, and a cleaning scraper for scraping and cleaning sediment is provided on the liquid sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com