Humidity control unit and method

An air chamber, ambient air technology, used in heating methods, lighting and heating equipment, space heating and ventilation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

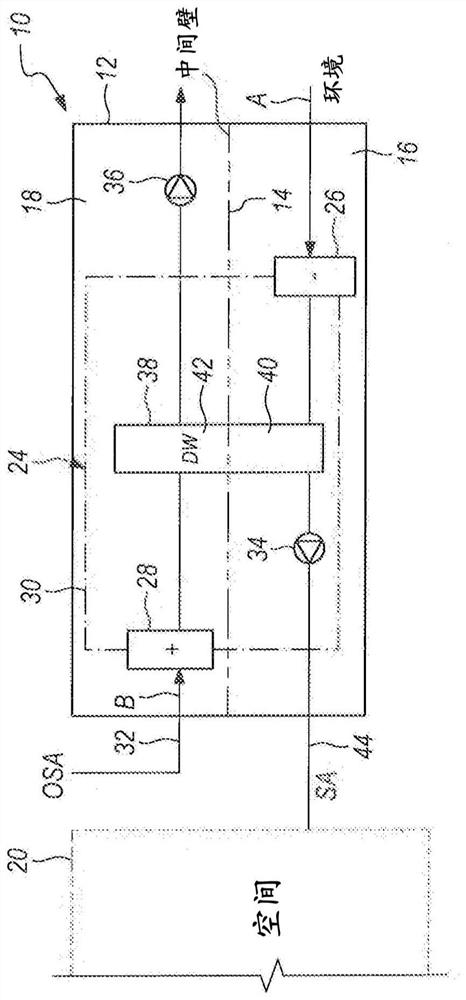

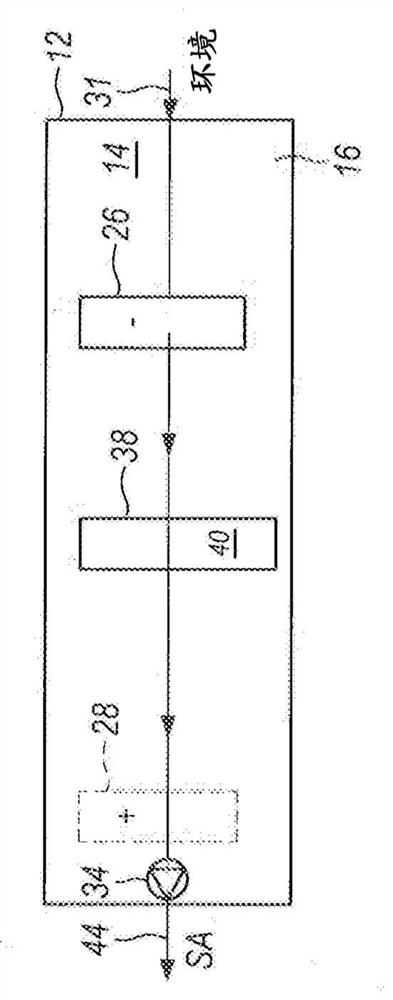

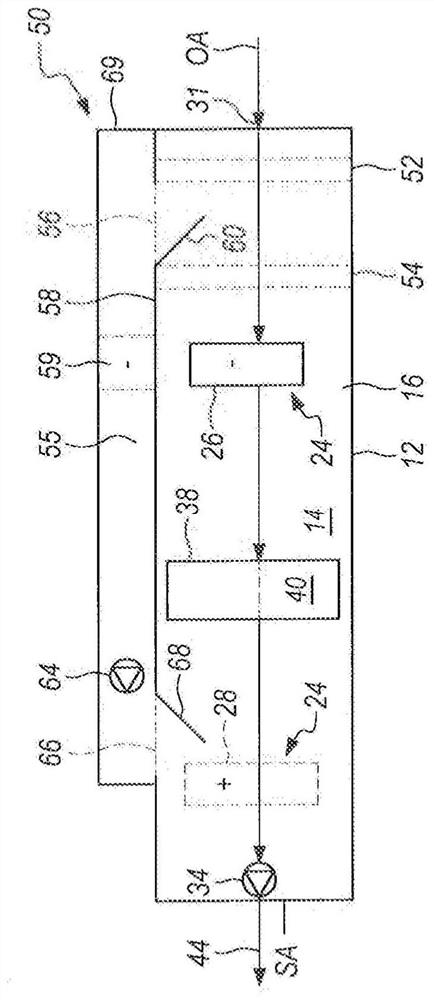

[0026] Referring now to the drawings in detail, and initially to FIGS. 1 and 2, there is shown a prior art air conditioning unit 10, generally of the type disclosed in US Patent Nos. 6,557,365, 6,711,907 and 7,047,751. The unit 10 includes an air chamber 12 having a dividing wall 14 generally centrally located in the air chamber and dividing the air chamber into separate air chambers, namely a first air chamber 16 and a second air chamber 18 . The unit is intended to use substantially only external ambient air in order to supply conditioned dehumidified air to the enclosure or space 20 under suitable or desired temperature and humidity conditions.

[0027] The prior art air conditioning unit of FIG. 1 also includes an associated direct liquid vapor compression expansion refrigeration system (DX) 24, which includes an evaporator or cooling coil 26 and a condenser coil 28, and not shown. The conventional compressor and expansion valve are connected by a liquid vapor pipeline 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com