Linear motor structure

A technology of linear motor and structure, applied in the direction of structural connection, manufacture of motor generators, magnetic circuit shape/style/structure, etc., can solve problems such as large stator volume, increase magnetic flux density, reduce weight and thickness, and increase thrust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Based on the above technical features, the main functions of the linear motor structure of the present invention will be clearly presented in the following embodiments.

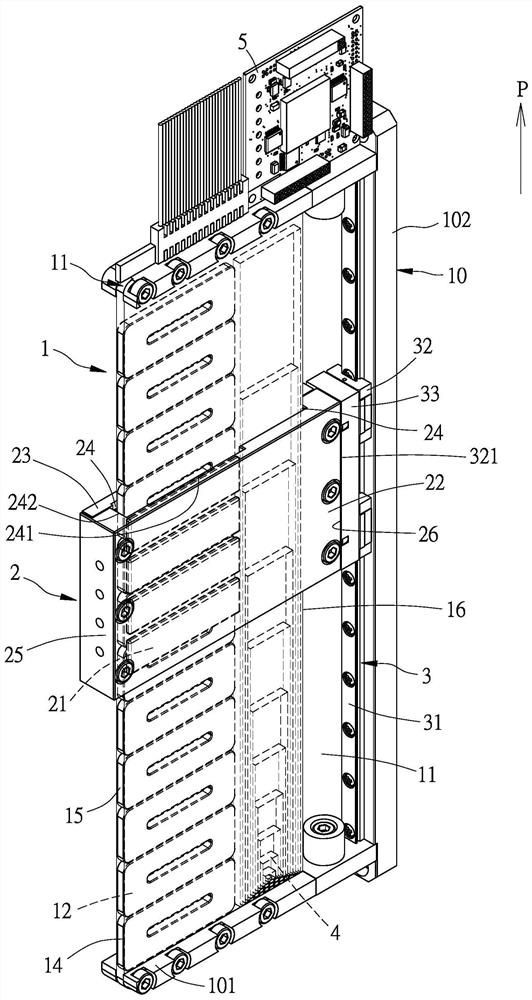

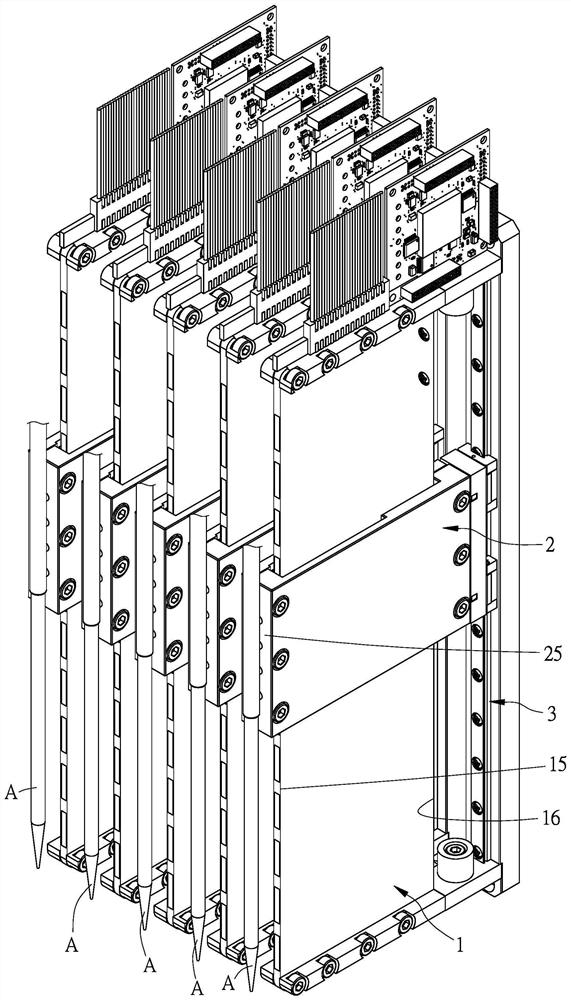

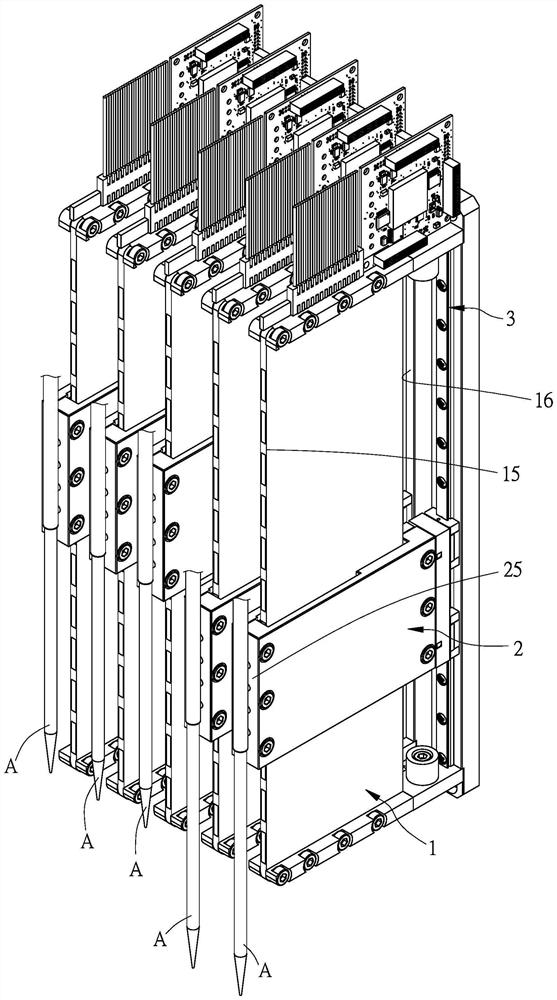

[0048] refer to figure 1 As shown, the linear motor of this embodiment includes a stator 1, a mover 2, a linear element 3 and a frame 10, wherein:

[0049] The stator 1 extends along an axial direction P. In this embodiment, the stator 1 is a printed circuit board 11 in the shape of a sheet, and the printed circuit board 11 is printed with a plurality of coils arranged along the axial direction P. 12, and the stator 1 is fixed by the frame 10, and the frame 10 is further fixed on a working machine table. The frame 10 includes two end plates 101 connected to the two ends of the printed circuit board 11, and a base plate 102 connected to the The plane of the two end plates 101, the coils 12 is an electromagnetic action surface 14, and the printed circuit board 11 has a first side portion 15 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com