Motor module

A technology of motors and printed circuit boards, applied in the field of motor modules, can solve the problems of difficult modularization and thinning, and difficult assembly of circuits and motor systems, so as to improve the qualified rate, improve the efficiency of motor assembly, and reduce the number of motor parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

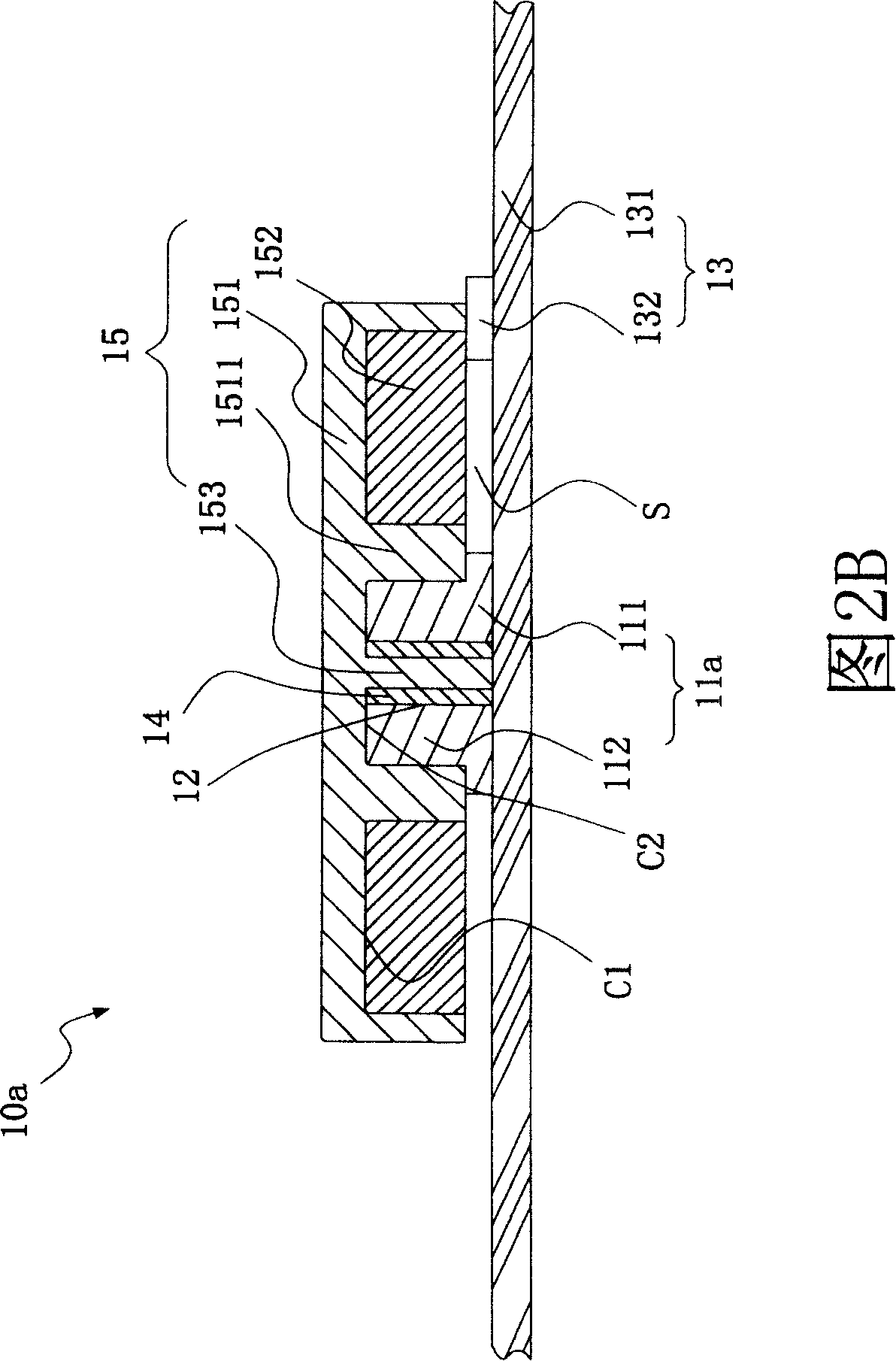

[0044] Please refer to Fig. 2A and Fig. 2B, a motor module of the present invention, the first embodiment of the motor module 10a includes a seat 11a, a set of holes 12, an electrical unit 13, a bearing 14 and a magnetic rotor unit 15 , the seat 11a has a supporting plate 111, and one end of the supporting plate 111 is extended with a set portion 112, and the set hole 12 runs through the above set portion 112, and extends through the supporting plate 111 for later description In other applications, the sleeve hole 12 can also be a stepped through hole, which runs through the sleeve part 112 and the bearing plate 111 at the same time, for the bearing 14 described later to be installed. Furthermore, the electrical unit 13 includes a printed circuit board 131 and several inductive components 132, the above-mentioned seat 11a is stacked on the printed circuit board 131, wherein the printed circuit board 131 forms a signal circuit 134 and a motor winding 135 by way of wiring, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com