Capacitive microbial desalination battery device and method applied to chemical tail water treatment

A microbial desalination and battery device technology, which is applied in the field of microbial desalination battery devices, can solve the problems of short service life of cathode electrodes and difficult recovery of added value salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Using the microbial desalination battery device of the present invention to treat the salt in the tail water of the pesticide production industry and recover the salt comprises the following steps:

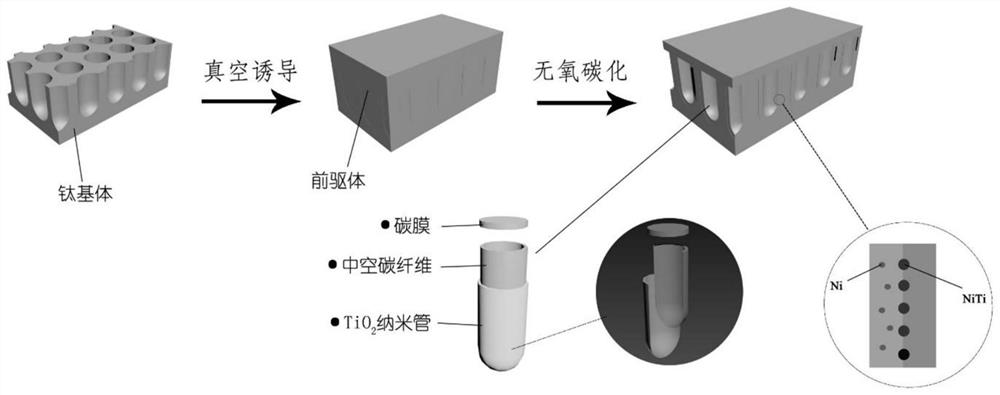

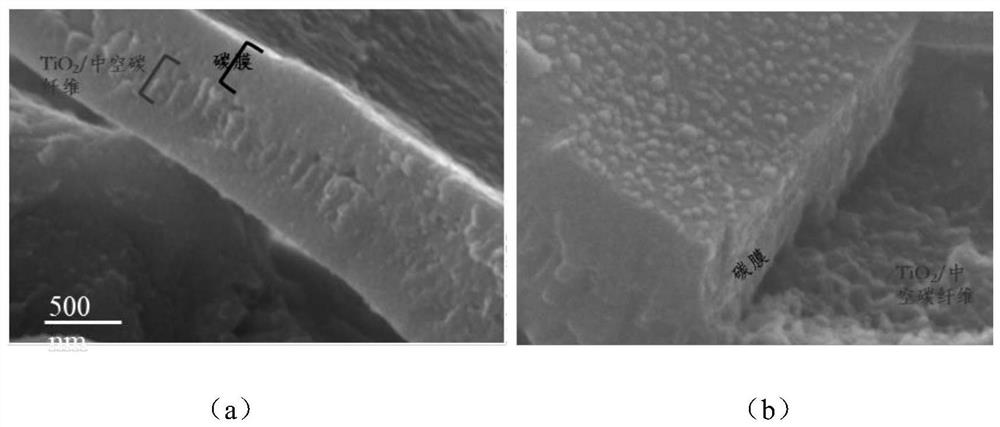

[0067] Step 1. Preparation of hollow carbon fiber-carbon film capacitor electrode

[0068] Step 1: Prepare 100mL of 120g / L glucose aqueous solution at room temperature, weigh 4g of nickel acetate solid, add it to the glucose aqueous solution, stir and dissolve to obtain the precursor.

[0069]Step 2: Put the titanium-based titania nanotube array (5cm×5cm×0.5mm, the thickness of the titanium matrix is 0.02mm) in a two-necked flask with stoppers, with the pure titanium side facing down, one port of the flask is connected to a vacuum pump, and the other port is connected to a tool Plug the constant pressure dropping funnel, and the precursor is housed in the funnel. Vacuumize to 0.03MPa, then open the constant pressure dropping funnel, drop the precursor into the two-necked...

Embodiment 2

[0079] Using the microbial desalination battery of the present invention to process pharmaceutical intermediates to produce salt in chemical industry tail water and to recover the salt comprises the following steps:

[0080] Step 1, preparing a hollow carbon fiber-carbon film capacitive electrode, which is the same as in Example 1;

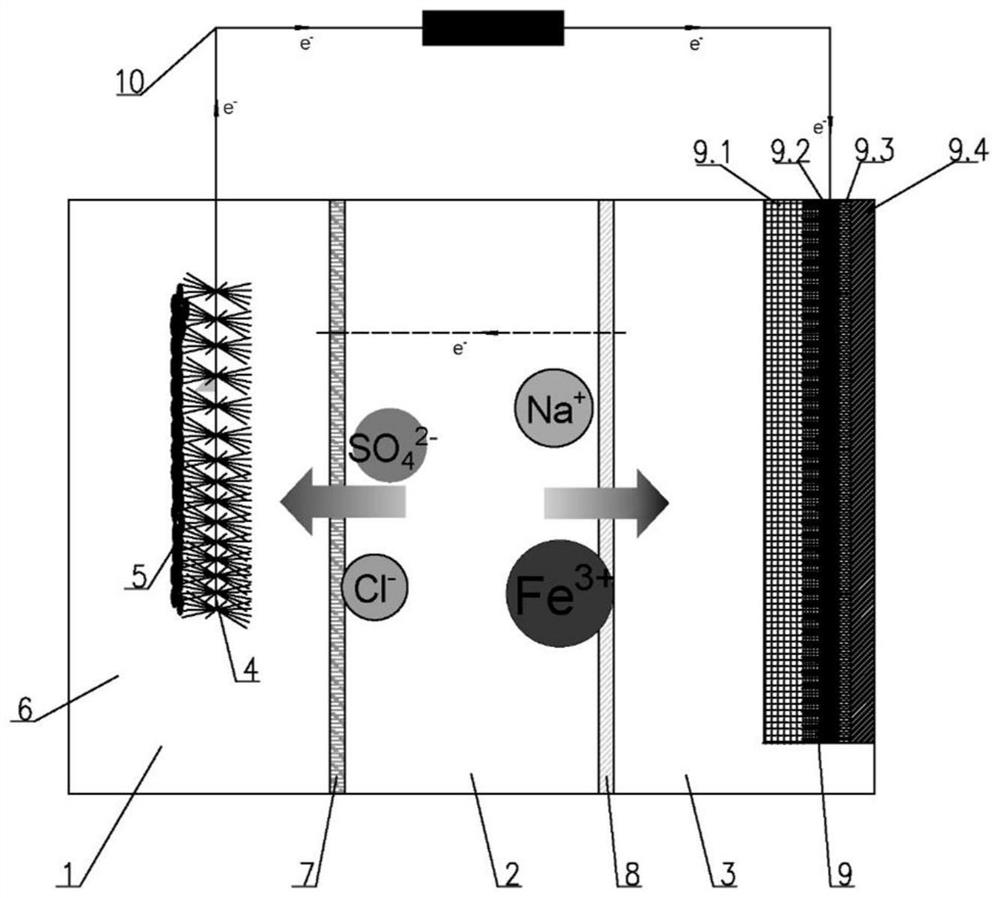

[0081] Step 2. Assembly of microbial desalination battery

[0082] Soak the anode carbon felt in the acclimated electricity-generating composite bacteria solution for more than 12 hours, then place the carbon felt in the anode chamber, and separate the anode chamber and the desalination chamber with an anion exchange membrane with a thickness of 0.25 mm; The prepared hollow carbon fiber-carbon film capacitor electrode is placed on the cathode, the capacitor layer is placed facing the desalination chamber, the catalytic layer is facing the air, and the cathode chamber and the desalination chamber are separated by a 0.25mm cation exchange membrane, ...

Embodiment 3

[0086] Using the microbial desalination battery of the present invention to integrally treat the residual organic pollutants and salt in the tail water of pesticide and chemical industry comprises the following steps:

[0087] Step 1. Preparation of hollow carbon fiber-carbon film capacitor electrode

[0088] Step 1: Prepare 100mL of 100g / L glucose aqueous solution at room temperature, weigh 2g of nickel acetate solid, add it to the glucose aqueous solution, stir and dissolve to obtain the precursor.

[0089] Step 2: Put the titanium-based titania nanotube array (5cm×5cm×0.5mm, the thickness of the titanium matrix is 0.02mm) in a two-necked flask with stoppers, with the pure titanium side facing down, one port of the flask is connected to a vacuum pump, and the other port is connected to a tool Plug the constant pressure dropping funnel, and the precursor is housed in the funnel. Vacuumize to 0.01MPa, then open the constant pressure dropping funnel, drop the precursor into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com