Composite material for electrode and preparation method of composite material

A composite material and electrode technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of limited high theoretical specific capacity and low conductivity of semiconductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] This example prepares a composite material for electrodes, including the following steps:

[0039] S1: Dissolve 2 mmol of hexahydrate nickel chloride and 9 g of sodium lauryl sulfate in 400 ml of water, and stir for 30 min to form a clear liquid;

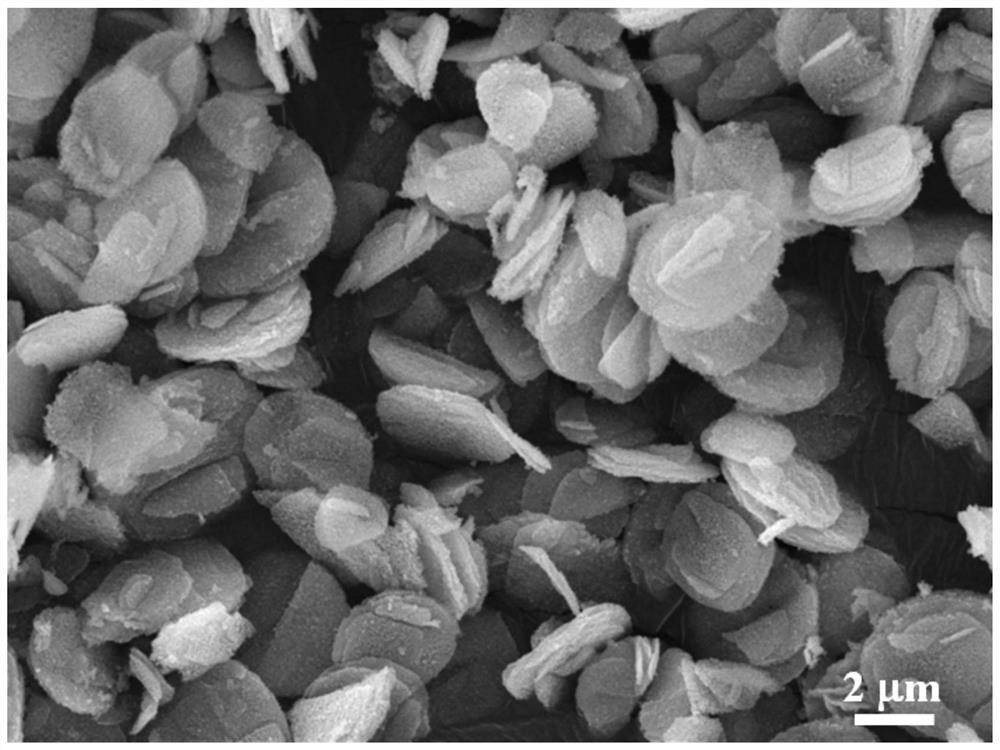

[0040] S2: Dissolve 2 mmol of potassium tetracyanonickelate in 400ml of water and stir for 30 min, then slowly add the solution prepared in step S1 into the potassium tetracyanonickelate solution, stir evenly, and leave it for 24 hours to obtain a nickel metal organic framework, such as figure 1 As shown, the synthesized nickel metal organic framework has a sheet-like structure with a diameter of about 2 μm. This two-dimensional structure is not easy to deform during the charging and discharging process of the battery, and can better maintain the capacity retention rate, and is not easy to decay. The large surface area can also provide a wide range of reaction sites for subsequent processing;

[0041] S3: Put nickel metal or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com