Pre-stressed anchor cable installation test system and method

A prestressed anchor cable, installation and testing technology, applied in the direction of applying stable tension/compression to test the strength of materials, measuring devices, instruments, etc., can solve the problems that the installation effectiveness of prestressed anchor cables cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

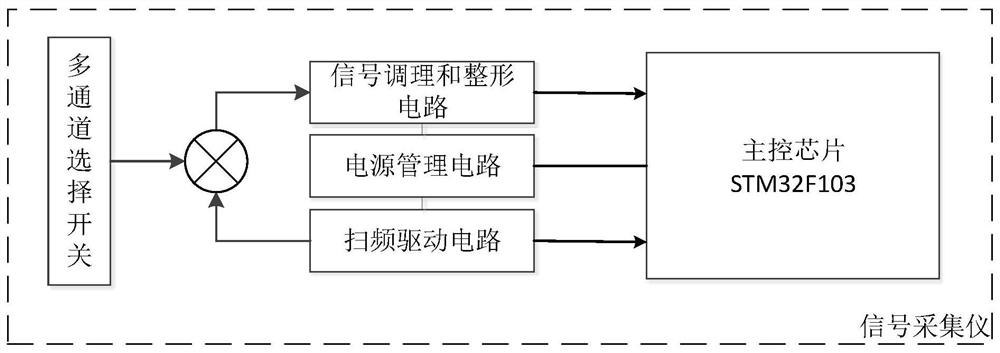

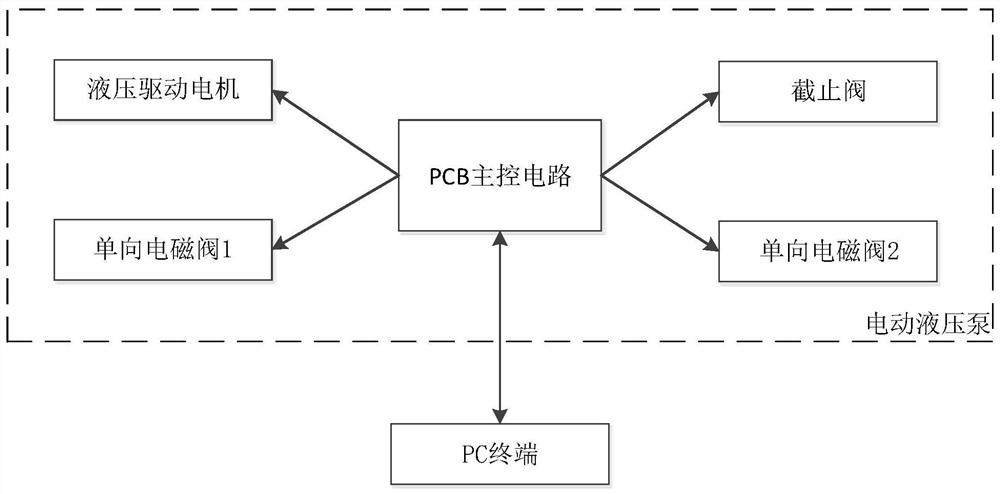

[0035] Such as figure 1 As shown, a prestressed anchor cable installation test system includes an anchor cable dynamometer, a signal acquisition instrument, an electric hydraulic pump, a hydraulic jack, and a PC terminal; the PC terminal communicates with the electric hydraulic pump; the electric The hydraulic pump is connected to the hydraulic jack; the PC terminal is used to receive the configured pressurization parameters and control the electric hydraulic pump to apply hydraulic pressure to the hydraulic jack according to the pressurization parameters, and the hydraulic jack is used for The prestressed anchor cable is pressurized; the anchor cable dynamometer is connected to the signal acquisition instrument; the signal acquisition instrument is connected to the PC terminal in communication; the anchor cable dynamometer is used to sense the prestressed cable dynamometer. The stress anchor cable is subjected to stress changes caused by pressurization to generate vibrating w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com