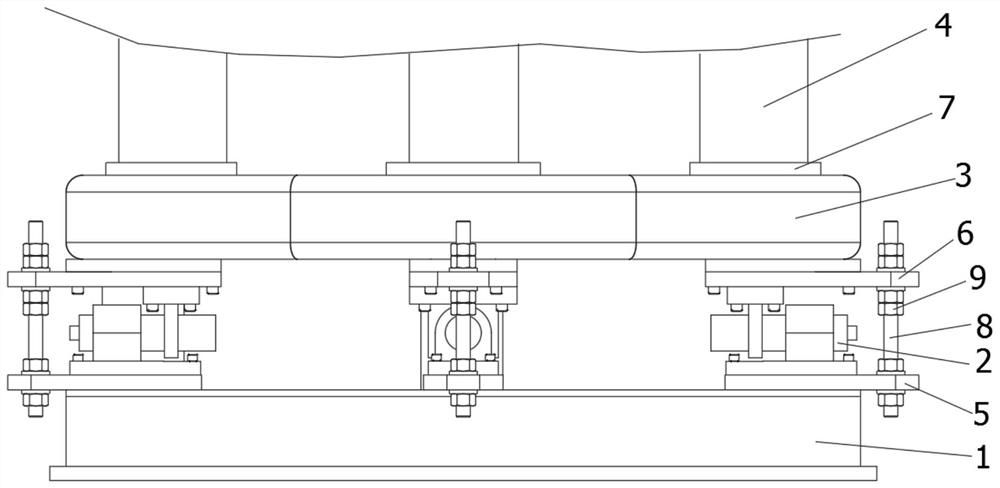

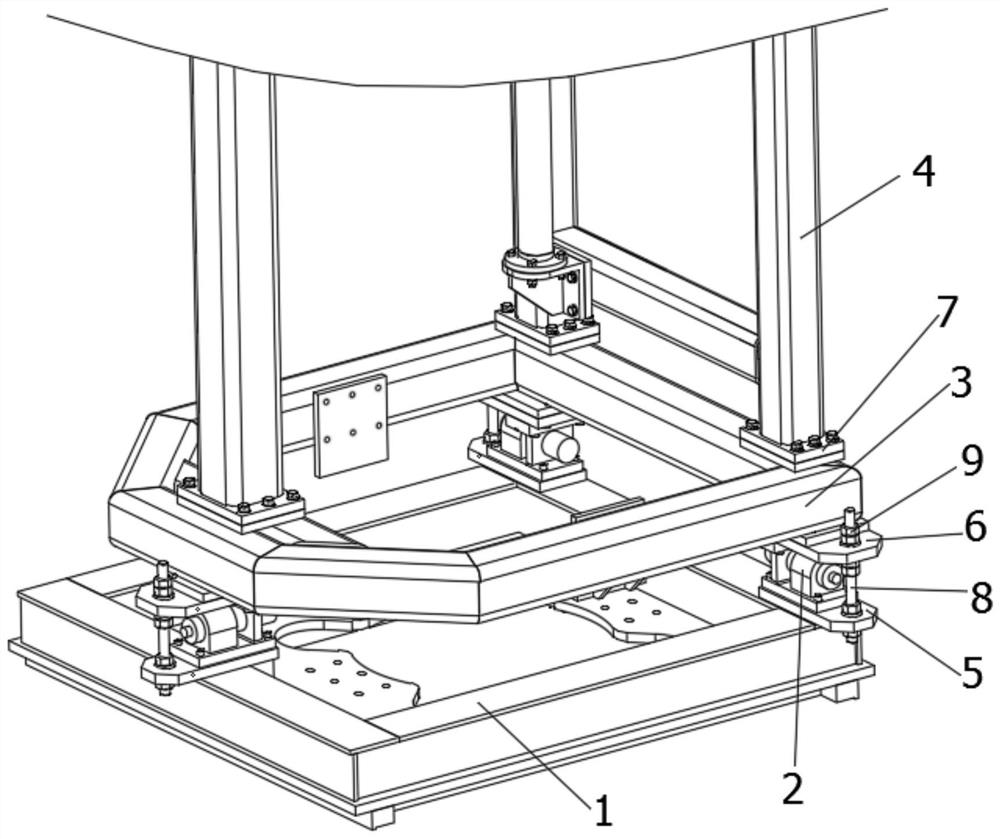

High-precision suspension frame weighing device of electroslag furnace

A weighing device and high-precision technology, applied in the field of special metallurgical equipment, can solve problems such as defects in the weighing method of the weighing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First of all, the design original intention of the present invention is explained, because existing weighing devices all adopt four supporting point weighing methods or three-point hinged weighing methods; The flatness of the points, the verticality and steel strength of the entire equipment frame are very high, and there are high requirements for the basic accuracy of the equipment. Otherwise, the sensors at the four support points will be unevenly stressed and overloaded, which will easily affect The accuracy of continuous weighing in the smelting process leads to the uncontrollability of the automatic melting rate smelting method; while the three-point hinged weighing method is connected by a hinge and its external fixed frame, but the external fixed frame is not included in the scale. Therefore, the accuracy of its continuous weighing will be affected by the pulling force of the external fixed frame; in order to improve the accuracy of weighing and make it more suita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com