A heat pipe soil treatment device

A soil treatment and heat pipe technology, applied in the field of heat pipes, can solve problems such as failure to save energy, and achieve the effects of improving the utilization rate of heat energy, increasing the liquid absorption capacity, and enhancing the effect of soil remediation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

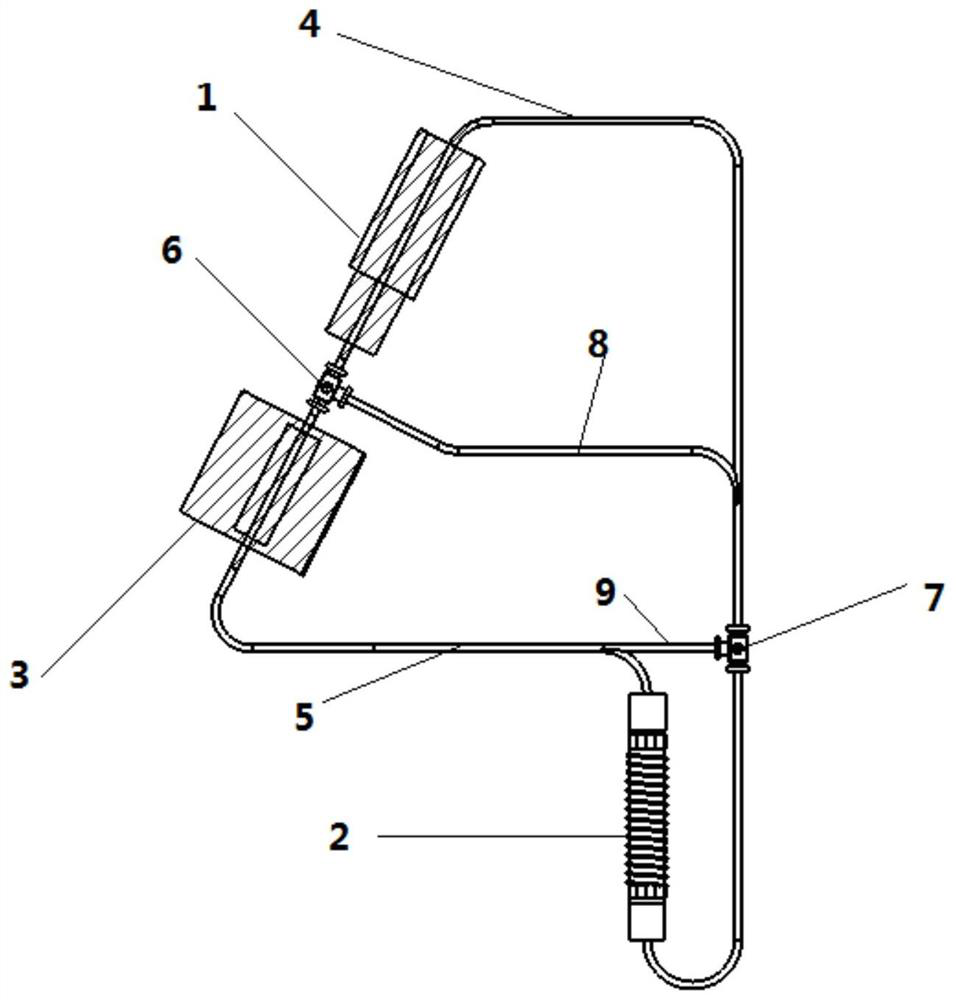

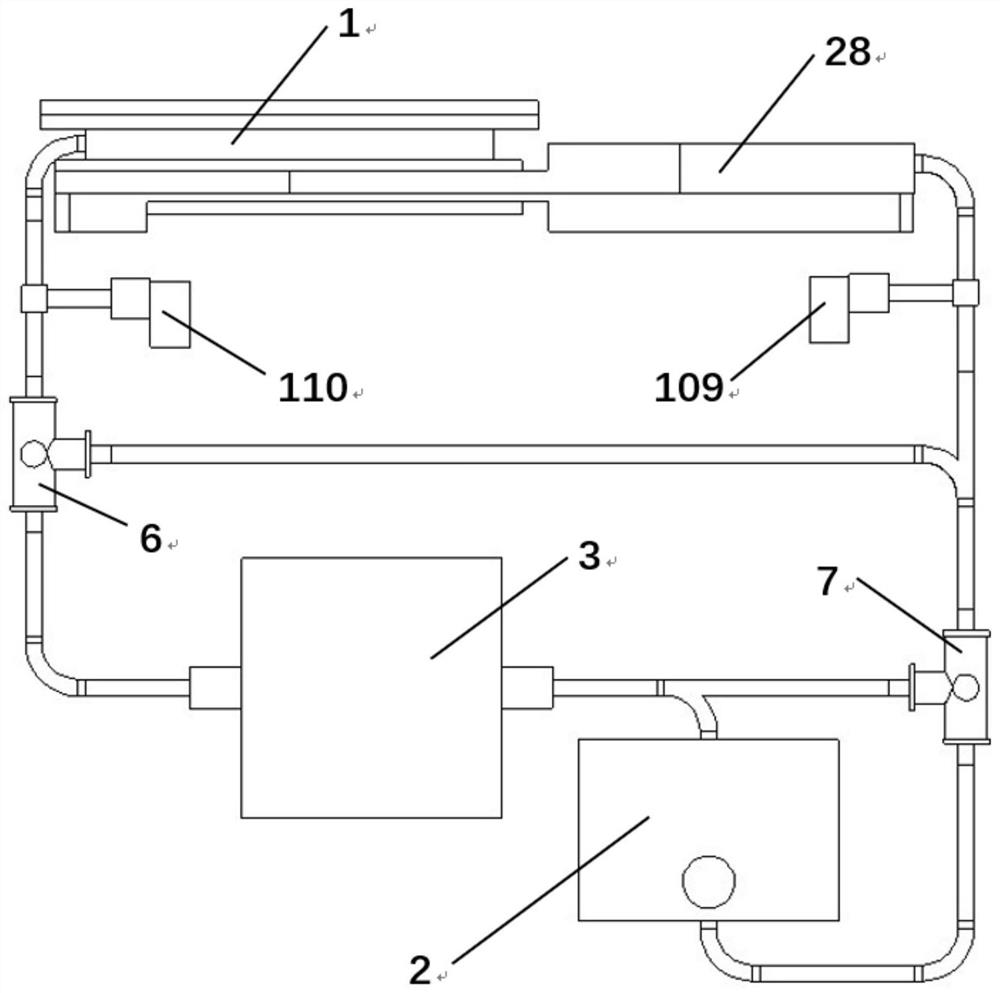

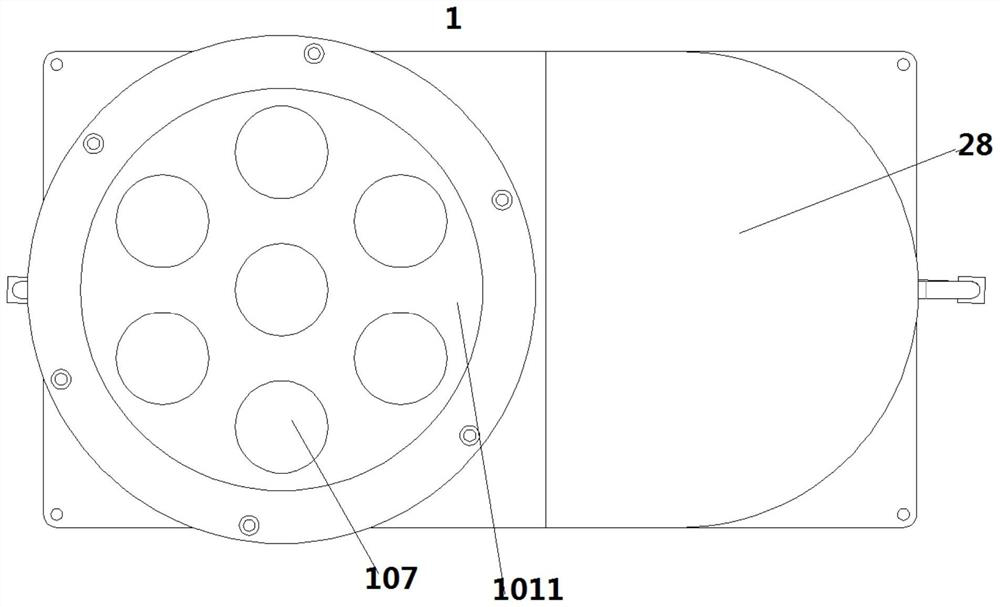

[0046] like figure 1 As shown, a loop heat pipe includes an evaporator 1, a condenser 2 and a heat accumulator 3, and the evaporator 1 and the condenser 2 form a circulation pipeline through a first pipeline 4 and a second pipeline 5, so The fluid absorbs heat and evaporates in the evaporator, then enters the condenser 2 to release heat through the first pipeline 5, and then circulates the fluid from the condenser 2 back to the evaporator 1 through the second pipeline 5, and the heat accumulator 3 Set in the second line. By setting the heat accumulator, excess heat can be stored in the heat accumulator, so as to better realize the utilization of heat.

[0047]Preferably, the heat pipe further includes a first three-way valve 7 and a second three-way valve 6, the first three-way valve 7 is set on the first pipeline 4, and the second three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com