A Large Precision Vibration Isolation Platform Based on Air Spring

An air spring and vibration isolation platform technology, applied in springs/shock absorbers, vibration suppression adjustment, mechanical equipment, etc., can solve problems such as being unsuitable for environmental cleanliness and require dust-free precision equipment laboratories, etc., to improve vibration isolation. effect, strong reliability, good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

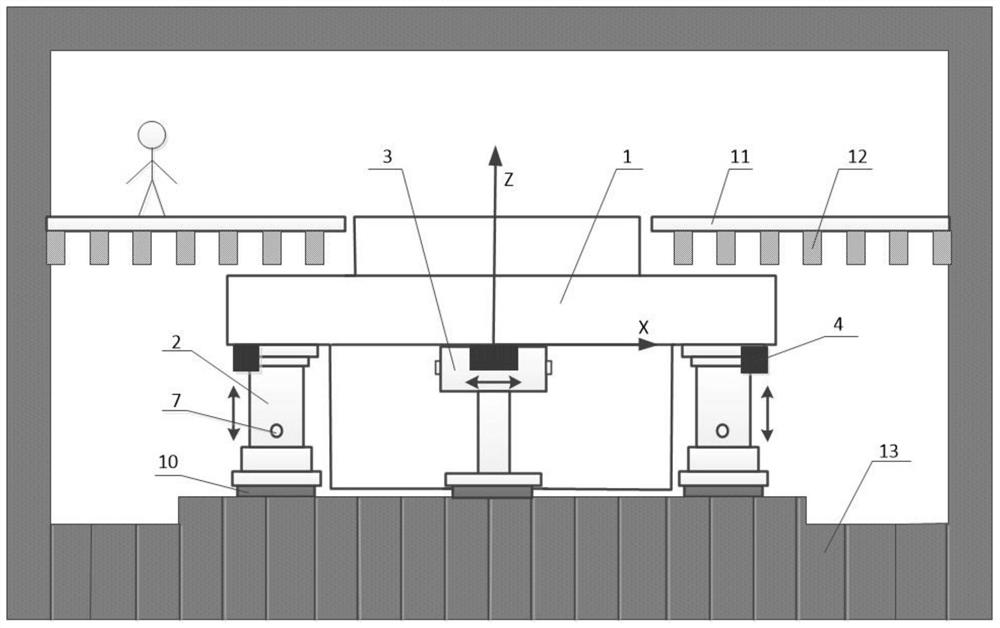

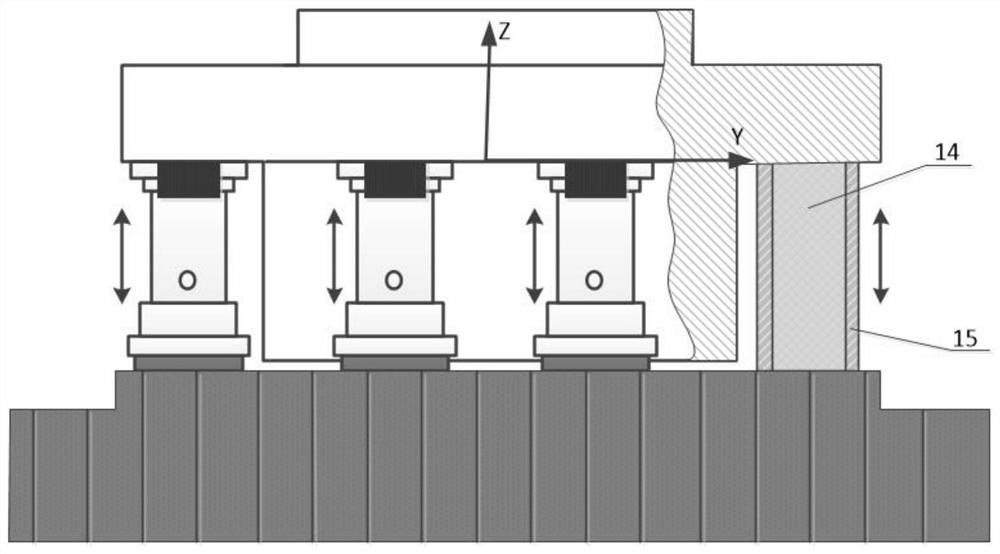

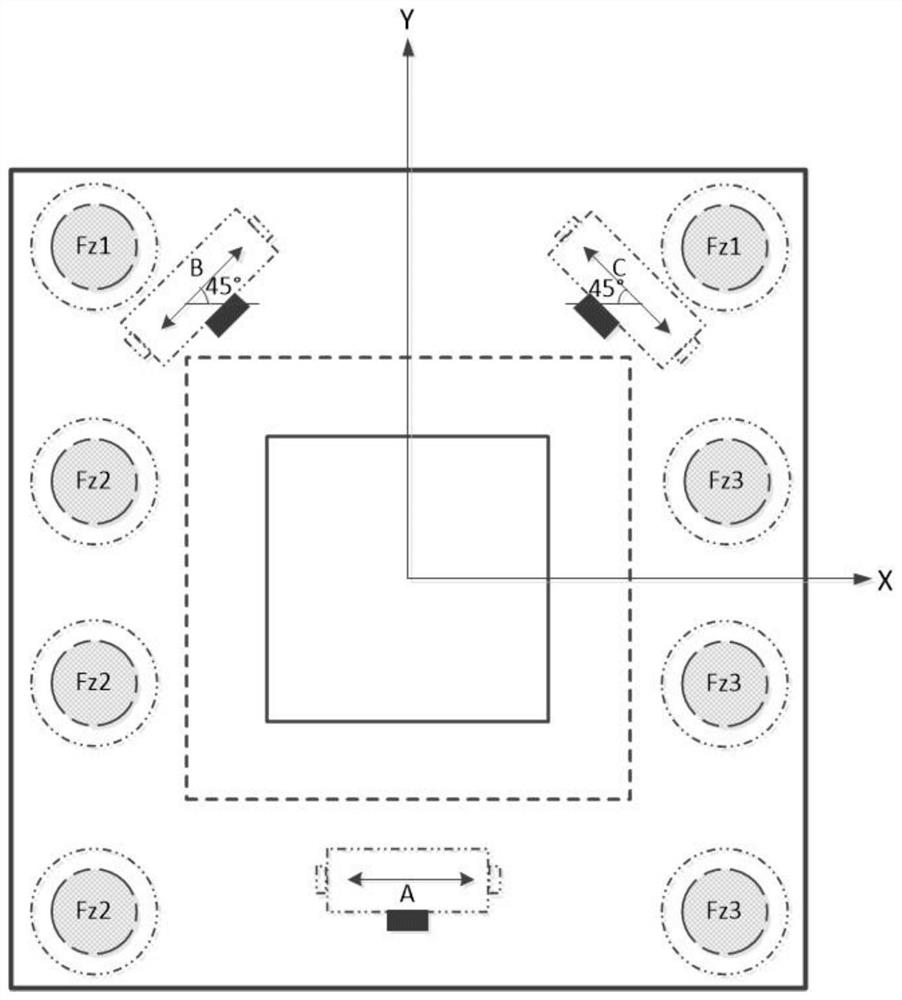

[0035] Such as figure 1 figure 2 As shown, the present invention is a high-precision large-scale vibration isolation platform system based on air springs. The main components include a load platform 1, a vertical air spring vibration isolator 2, a horizontal air spring vibration isolator 3, a pneumatic system and a control system. The load platform 1 is supported by several vertical air spring isolators 2 evenly arranged in two rows; the horizontal air spring isolator 3 is placed in the middle of two rows of vertical air spring isolators; each air spring isolator is equipped with There is a feedback sensor 4 to detect the pressure of the air spring cavity and the acceleration information of the corresponding position of the load platform 1; the control system includes a controller 5, a power unit and a servo valve, the controller is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com