A stepped n-speed wet clutch structure

A wet clutch, stepped technology, used in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as waste, achieve long service life, compact structure, and reduce structural complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

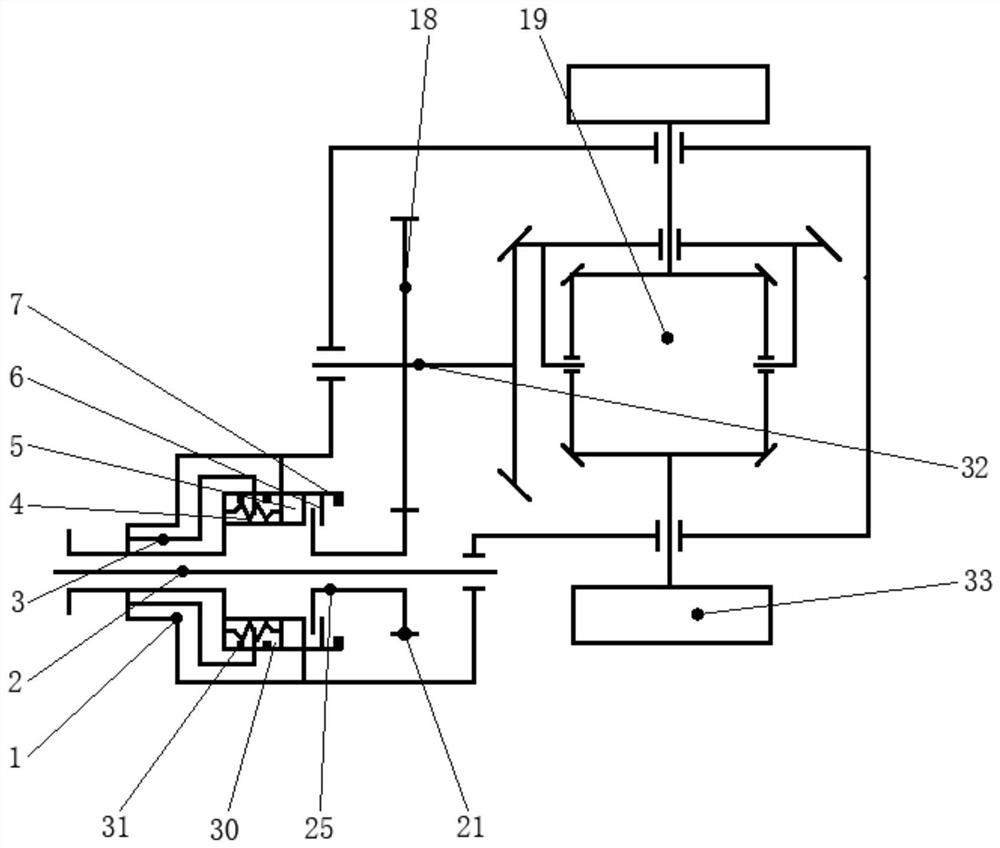

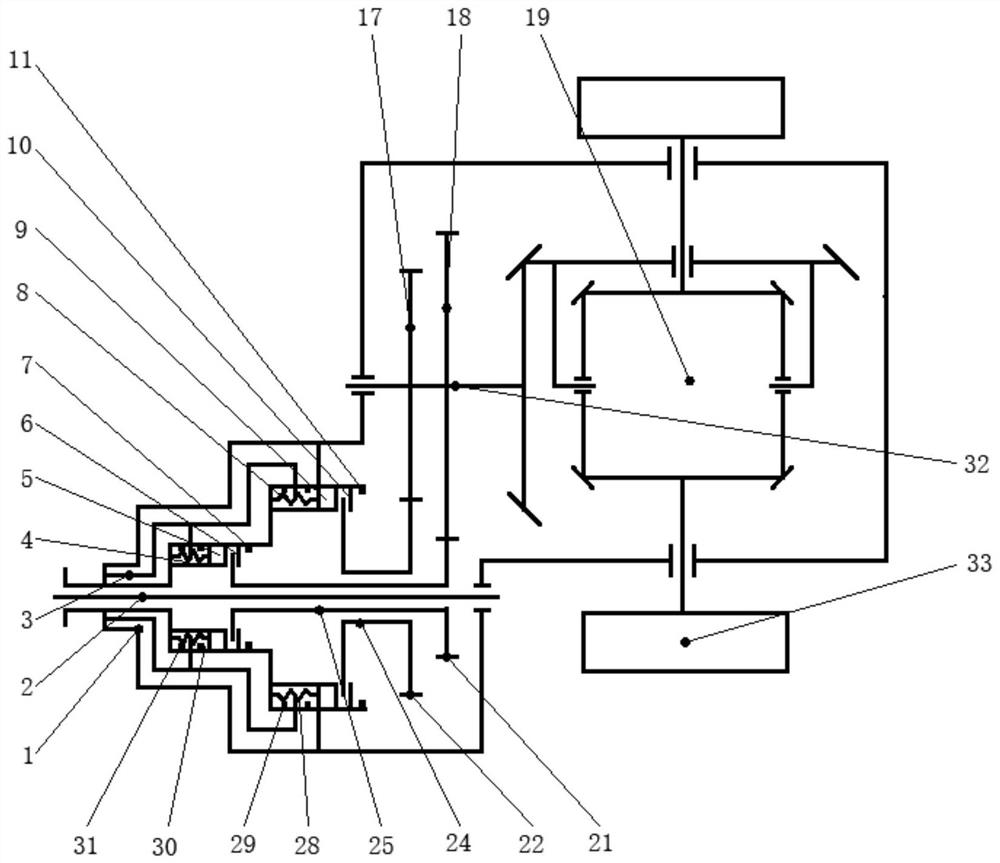

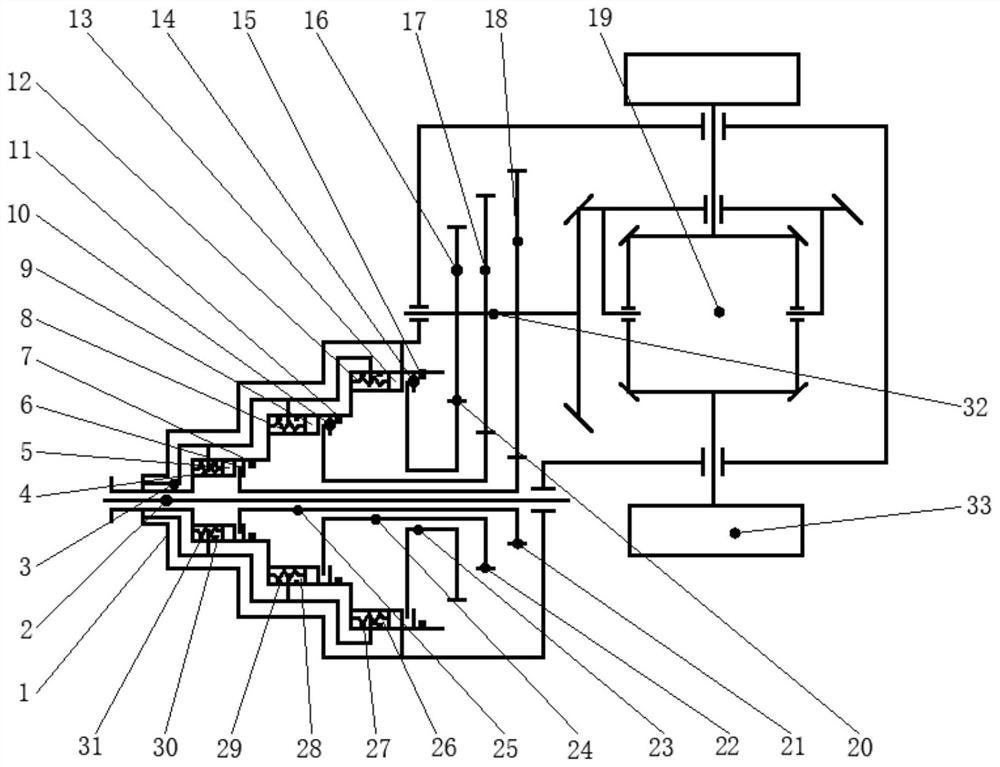

[0020] combine figure 1 The present invention is further described with specific examples, appended figure 1 It is a simplified structural diagram of the stepped third gear clutch proposed by the present invention, taking the third gear as an example. Including housing 1, input shaft 2, oil delivery pipe 3, first-gear return spring 4, first-gear piston 5, first-gear clutch disc 6, first-gear stop washer 7, second-gear return spring 8, second-gear piston 9, second-gear clutch Plate 10, second gear stop washer 11, third gear return spring 12, third gear piston 13, third gear clutch plate 14, third gear stop washer 15, third gear far gear 16, second gear far gear 17, first gear far gear 18. Differential 19, third-gear ring gear 20, first-gear ring gear 21, second-gear ring gear 22, third-gear shaft 23, second-gear shaft 24, first-gear shaft 25, third-gear hydraulic chamber 26, third-gear sealing washer 27, second gear hydraulic cavity 28, second gear sealing washer 29, first ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com